Automatic wire clamping and drawing device

A stretching device and wire clamping technology, applied in the field of new automatic auxiliary equipment, can solve the problems of large waste of manual operation time, large size error, low efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

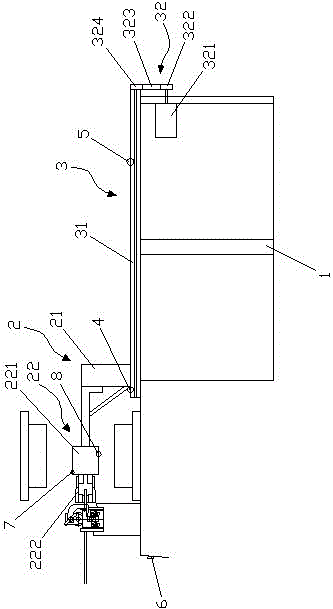

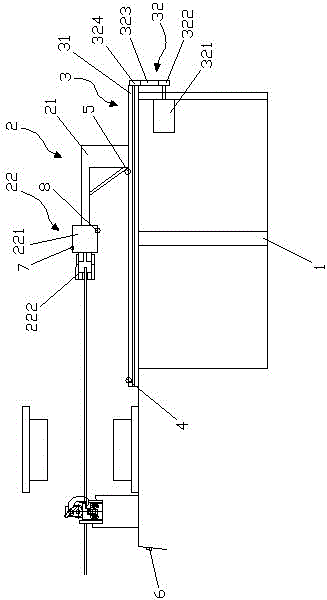

[0021] Below with reference to accompanying drawing and in conjunction with embodiment, describe the present invention in detail:

[0022] Please refer to figure 1 , figure 2 , the present invention provides an automatic clamping and stretching device, comprising: a frame 1, a clamping fixture 2 and a stretching device 3 arranged on the frame 1, the frame 1 is a metal frame, and the pulling The extension device 3 includes a guide rod 31 and a drive unit 32, the drive unit 32 is in transmission connection with the guide rod 31, and the drive unit 32 is composed of a servo motor 321, a first gear 322 connected with the rotor of the servo motor 321, The second gear 324 is connected to the first gear 322 through the belt 323. The servo motor 321 is provided with a power switch (not shown), and the power switch is activated, and the servo motor 321 drives the first gear. 322 operation, the first gear 322 drives the second gear 324 to rotate through the belt 323 under the transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com