Trailer card cycloidal tool

A cycloid and jig technology, applied in the field of jigs, can solve problems such as easy lifting of wires, unstable placement, long manual operation time, etc., to reduce manual operation time, quickly place and fix, and improve work efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

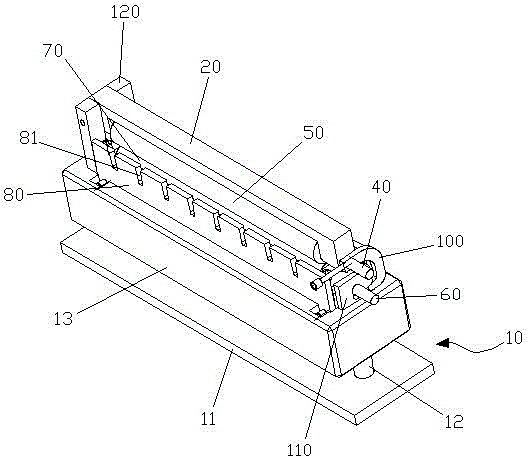

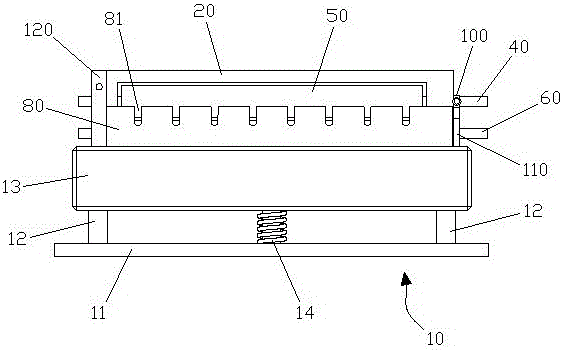

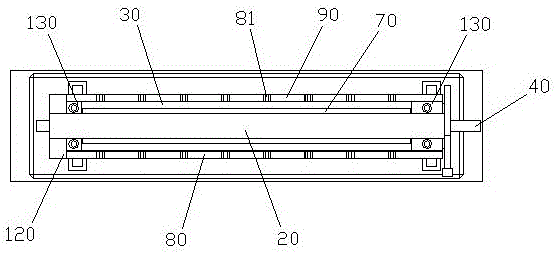

[0027] Below with reference to accompanying drawing and in conjunction with embodiment, describe the present invention in detail:

[0028] Such as Figure 1~5 As shown, a tail clip cycloid fixture includes: a base 10, and an upper clamp 20 and a lower clamp 30 arranged on the base 10, the upper clamp 20 is provided with a first groove (not shown), The upper bearing roller 50 is rotated through the first pin 40 in the first groove, and the second groove (not shown) is opened on the lower clamp 30, and the second groove is passed through the second pin 60. A lower bearing roller 70 is provided for rotation, and a limiting space (not shown) is formed between the upper bearing roller 50 and the lower bearing roller 70 to limit the up and down shaking of the wire rod, and the front and rear sides of the lower clamp 30 are respectively provided with front plates 80 and the rear plate 90, the front plate 80 and the rear plate 90 are provided with a number of parallel and one-to-one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com