A method of improving the surface finish of wooden mould

A technology of smoothness and wood mold, applied in casting and molding equipment and other directions, can solve the problems of long manual operation time, easy sand sticking, mold surface damage, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific examples. In general, the present invention provides a method for improving the surface finish of wooden formwork, and the following examples illustrate the features of the present invention.

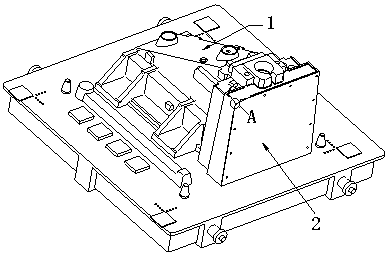

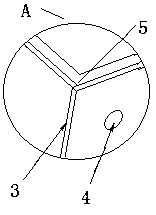

[0015] The invention provides a method for improving the plane finish of wooden formwork, according to an embodiment of the invention, figure 1 It is a structural representation of the method of the present invention, figure 2 It is the partial A structure schematic diagram of wood formwork of the present invention, with reference to figure 1 with figure 2 As shown, the method includes the following steps: (1) Designing the mold: use software to design the wooden mold structure, and reduce all plane parts of the wooden mold 1 by 1 mm for installing the aluminum plate 3. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com