Intelligent rotary adsorption feeding and discharging device for anti-overflow cover plates of electric rice cooker covers

An adsorption type, electric rice cooker technology, applied in the directions of feeding devices, positioning devices, storage devices, etc., can solve the problems of increased shutdown probability of automatic loading and unloading devices, no buffering function, and increased labor costs, so as to reduce manual work time. , Improve the efficiency of loading and unloading, and save space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

[0025] The object of the present invention is to provide an intelligent rotary adsorption type electric rice cooker pot lid overflow prevention cover plate loading and unloading device for the deficiencies in the prior art.

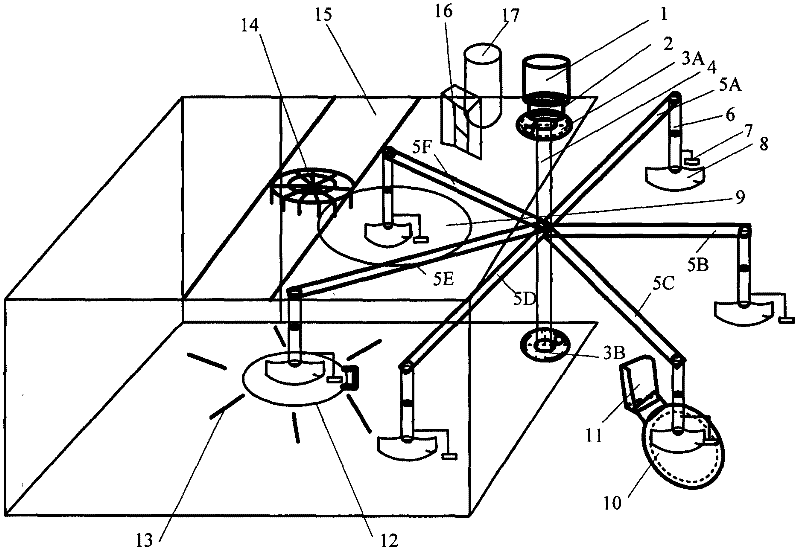

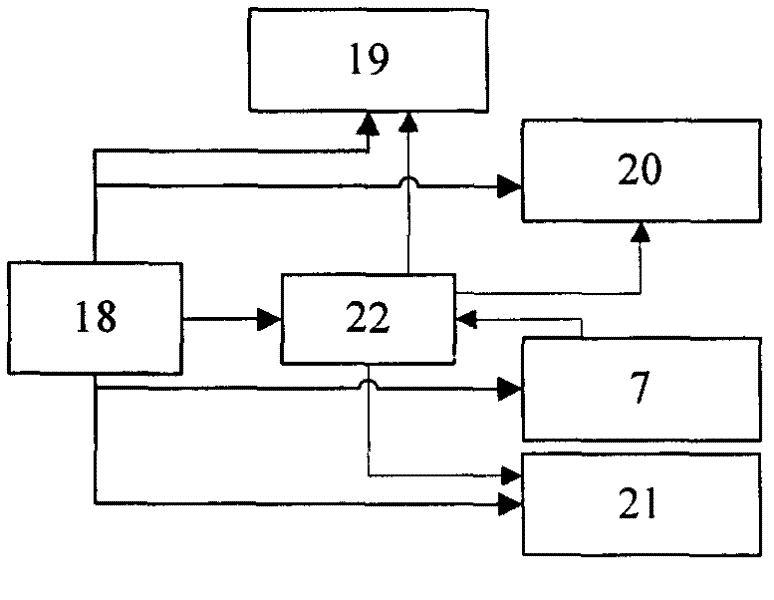

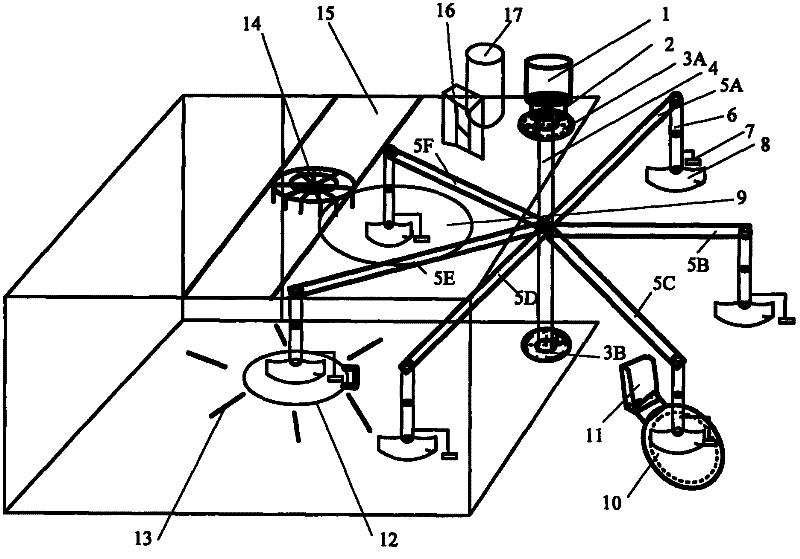

[0026] The present invention includes a stepper motor 1, a shaft coupling 2, an upper bearing 3A, a lower bearing 3B, a transmission shaft 4, a controller 16, an air source 17, mechanical arms 5A, 5B, 5C, 5D, 5E, 5F, and a retractable cylinder 6. Limit contact switch 7, suction cup 8, U-shaped card slot 11, etc.

[0027] The stamping machine 15 is rectangular (0.65m in length, 0.65m in width, and 0.70m in height). The stamping processing station 12 is located at the center of the bottom surface of the stamping machine 15. A stamping head 14 is installed directly above the stamping processing station 12. The stamping processing station 12 is evenly dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com