Combined rotating paddle no-seal paper pulp stirring equipment assembly and use method thereof

A rotary paddle and no seal technology, which is applied to mixers with rotary stirring devices, mixer accessories, chemical instruments and methods, etc., can solve the problems of inconvenient operation for workers, uneven mixing of single-axis rotation, waste of resources, etc., and achieve The effect of saving manual work time, convenient and safe operation, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in combination with specific embodiments.

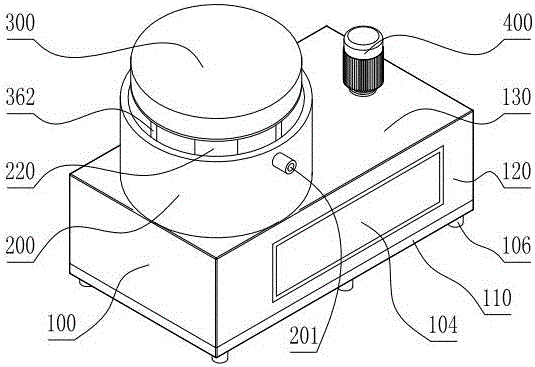

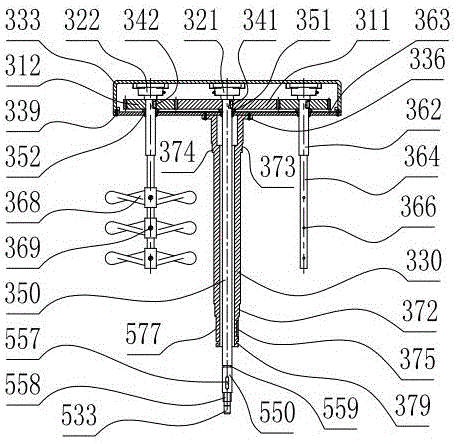

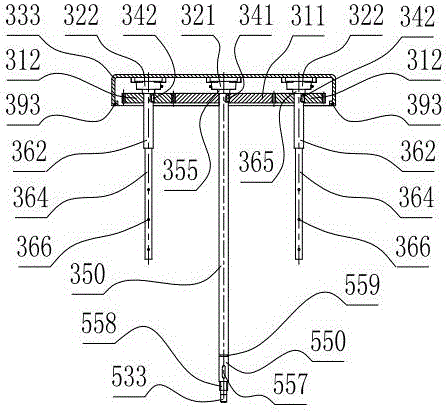

[0046] Such as Figure 1 to Figure 4 as well as Figure 5 with Figure 10 As shown, the combined rotary blade sealless stirring pulp equipment assembly and its use method include: a base part 100, a pulp stirring tank 200, a combined rotating mechanism 300 and a motor 400, and both the motor 400 and the pulp stirring tank 200 are located at the base Above the seat part 100, the shell of the base part 100 is composed of the base bottom plate 110, the side plates 120 around the base and the base cover plate 130. Composed of the slurry tank bottom plate 230, the combined rotating mechanism 300 includes a driven shaft 350, a revolving hollow shaft 330, a gear box 333, a gear box cover 363, a central gear 311, an autorotation gear 312, and an autorotation paddle shaft 362 and stirring blades 368, a pulp feed pipe 201 and a pulp discharge pipe 202 are arranged on the pulp tank...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com