Visual measurement twisting system method and device for multifunctional aluminum electrolysis unit

A multifunctional unit and visual measurement technology, applied in the field of aluminum electrolysis, to reduce labor intensity, reduce manual work time, and improve safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

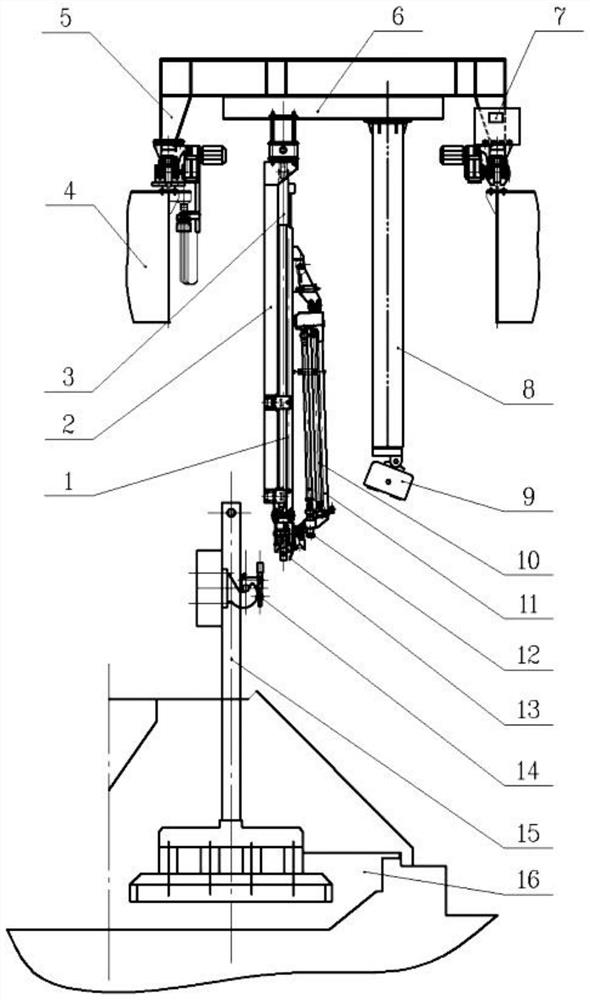

[0028] Such as figure 1 As shown, the present invention is constituted as follows: including an anode lifting frame device 1, a fixed guide frame 2, a twisting and lifting servo hydraulic cylinder 3, a unit cart device 4, a unit trolley device 5, a tool turning mechanism 6, a control device 7, Visual lifting mechanism 8, visual sensor 9, head screwing frame lifting servo cylinder 10, fixture screwing head frame device 11, clamp screwing head 12, anode guide rod chuck 13, small box fixture 14, anode guide rod 15, electrolytic cell 16.

[0029] The unit trolley device 4 runs on the track of the aluminum electrolysis workshop, the unit trolley device 5 runs on the rails on the two main beams of the trolley, and the tool turning mechanism 6 is installed on the unit trolley device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com