Patents

Literature

51results about How to "Improve the safety of production operations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

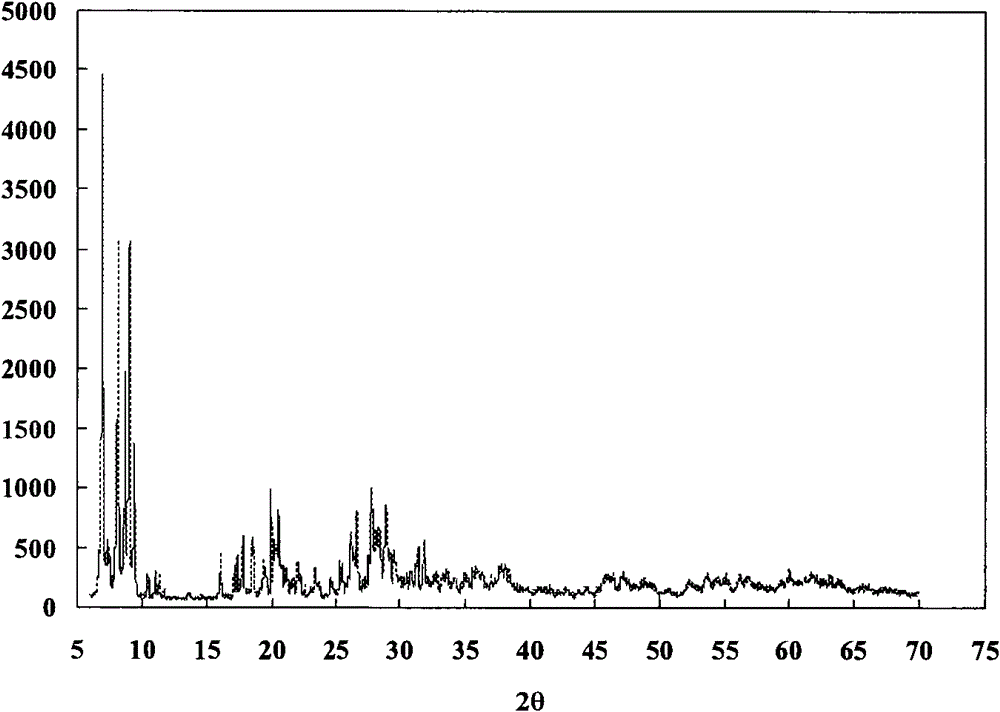

Process for preparing alpha-arbutin through fermentation

ActiveCN1635139AIncrease productionReduce manufacturing costFermentationXanthomonas campestrisALPHA-ARBUTIN

The invention relates to a method for preparing alpha-arbutin which comprises steps of preparing slope seeds, selecting culture mediums, optimizing reaction conditions and extracting products and so on. The invention employs Xanthomonas campestris to ferment to produce the alpha-arbutin without use of organic solvents during the production and generation of harmful substances during the fermentation process. The invention has advantages of low production cost, simple process, and safe operation. And the alpha-arbutin yield produced by the method is high, the alpha-arbutin content in fermentation liquor is 8-11g / L, and the conversion rate of the hydroquinone can be 91%. The alpha-arbutin can obviously inhibit activities of tyrosinase, reduce tyrosinase deposition in skins, and bleach skins, remove freckles.

Owner:CHENGZHI LIFE SCI CO LTD

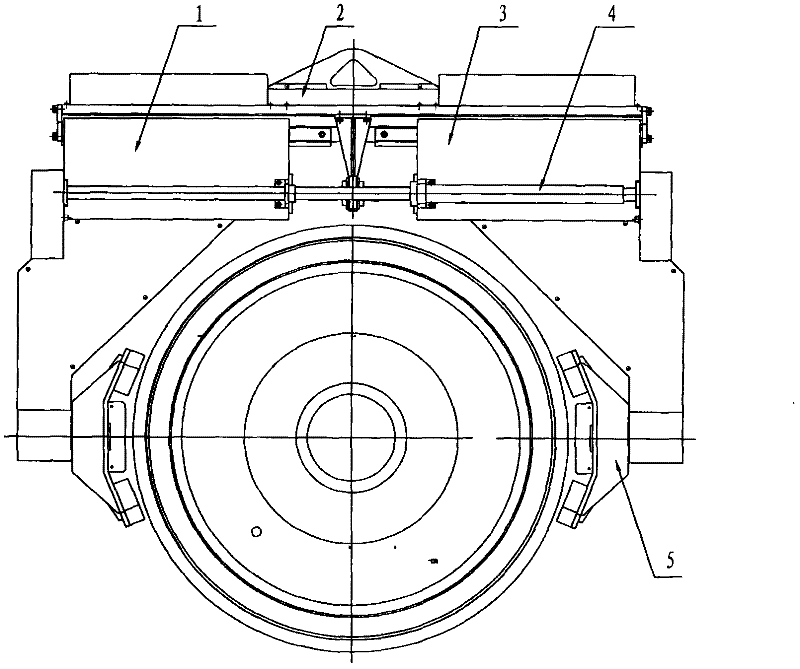

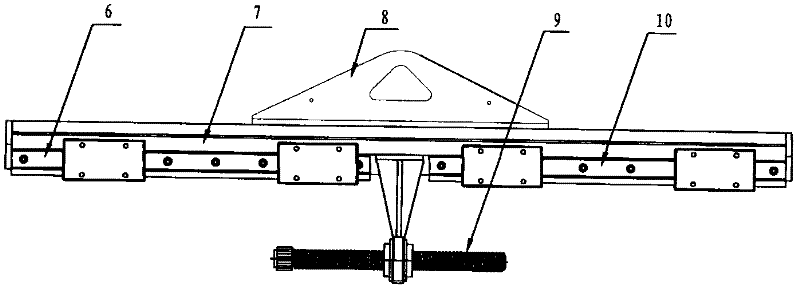

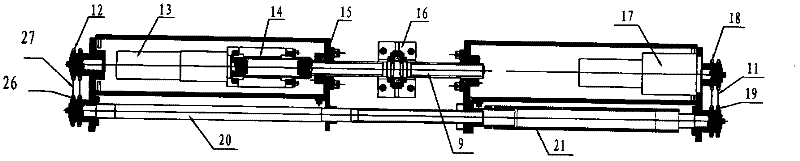

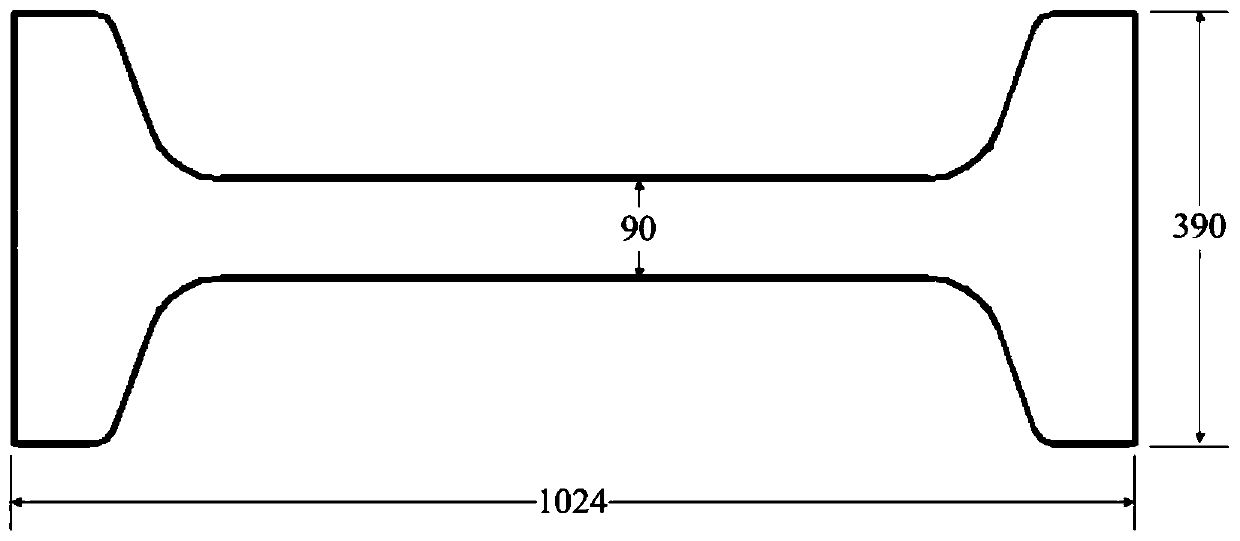

Wheel turning sling of high speed motor train unit

ActiveCN102408061AReduce turnaround timeIncrease productivityLoad-engaging elementsSprocketDouble chain

The invention discloses a wheel turning sling, which solves the problem that the sling needs to be replaced for two times in turning over the wheel once in the prior art. The wheel turning sling comprises a lifting beam (2), left and right lifting arms and a transmission mechanism (4); a screw rod (9) is disposed in a screw rod bearing seat (16) in the middle of a transverse beam (7); screw rod nuts are disposed at both sides of the screw rod (9); the screw rod nuts are fixedly connected with the lifting arms movably disposed on guide rails; jaws (5 ) are correspondingly disposed at the lowerends of the left and right lifting arms (1 and 3); one end of the screw rod (9) is fixedly connected with the output shaft of a clamping speed reducing motor (13) through a spline housing (14); a rotary speed reducing motor (17) and the clamping speed reducing motor (13) are arranged on the lifting arm (2); a right rotary double chain wheel (18) is disposed on the output shaft of the rotary speedreducing motor (17); and chains are disposed among a jaw turning chain wheel, a rotary active chain wheel and a force transmission chain wheel. The wheel turning time is shortened by the wheel turning sling.

Owner:ZHIBO LUCCHINI RAILWAY EQUIP

Preparation method of silicotungstic heteropoly acid

ActiveCN102744088AImprove the safety of production operationsPhysical/chemical process catalystsOrganic solventHydrogen phosphate

The invention relates to a preparation method of silicotungstic heteropoly acid, and aims to mainly solve the problem that employment of inflammable low-boiling point organic extracting agent can result in poor production security in the prior art. The method of the invention includes the following steps of: a) dissolving sodium tungstate and sodium hydrogen phosphate in water to generate a mixed solution of phosphotungstic acid and sodium phosphotungstate under heating and acidic conditions, with the sodium tungstate and the sodium hydrogen phosphate in a weight ratio of 1:0.1-1:10; b) dissolving CnH2n+1N<+>Cl<-> in an organic solvent to obtain an organic solution of CnH2n+1N<+>Cl<->, wherein n is a positive integer from 10 to 30, and with the sodium tungstate adding amount as the reference, the adding amount of CnH2n+1N<+>Cl<-> content is 0.01-1 mol / g sodium tungstate; and c) adding the organic solution of CnH2n+1N<+>Cl<-> into the mixed solution of phosphotungstic acid and sodium phosphotungstate for reaction, then carrying out centrifugation, washing, drying and roasting on the product, thus obtaining silicotungstic heteropoly acid. The technical scheme in the method of the invention well solves the problem, and can be used in the industrial production of silicotungstic heteropoly acid.

Owner:CHINA PETROLEUM & CHEM CORP +1

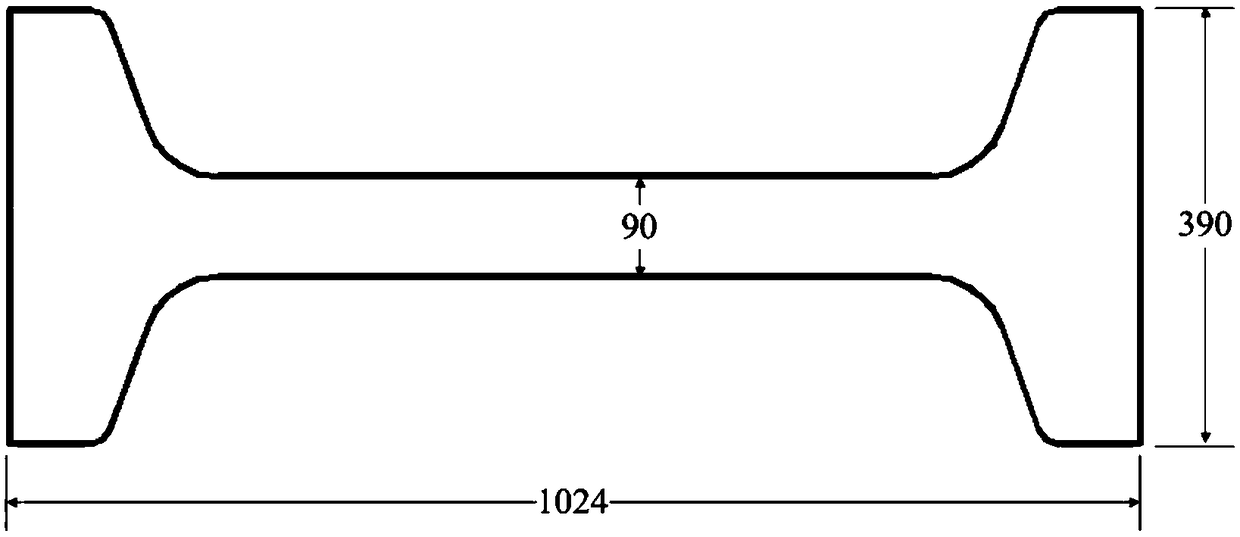

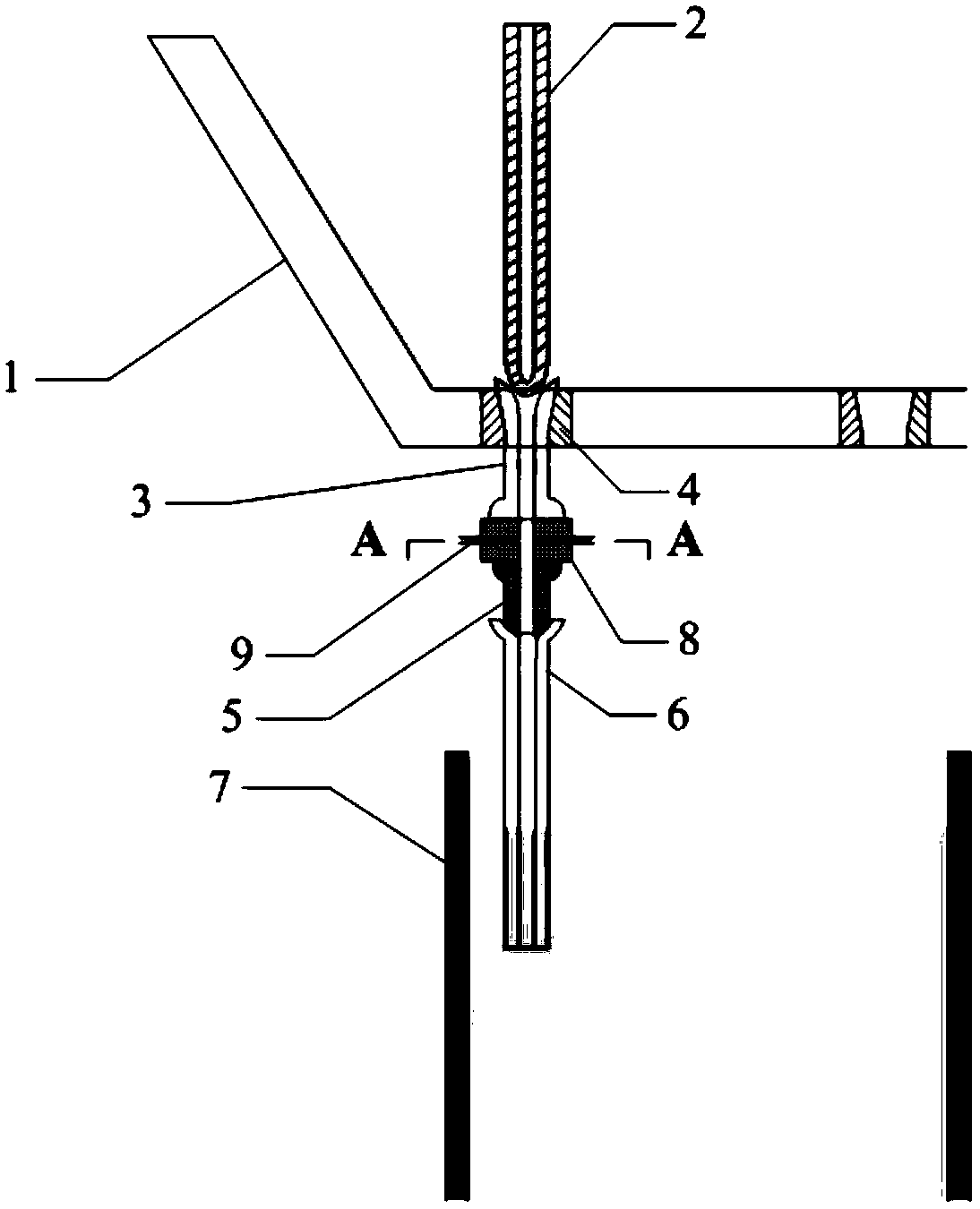

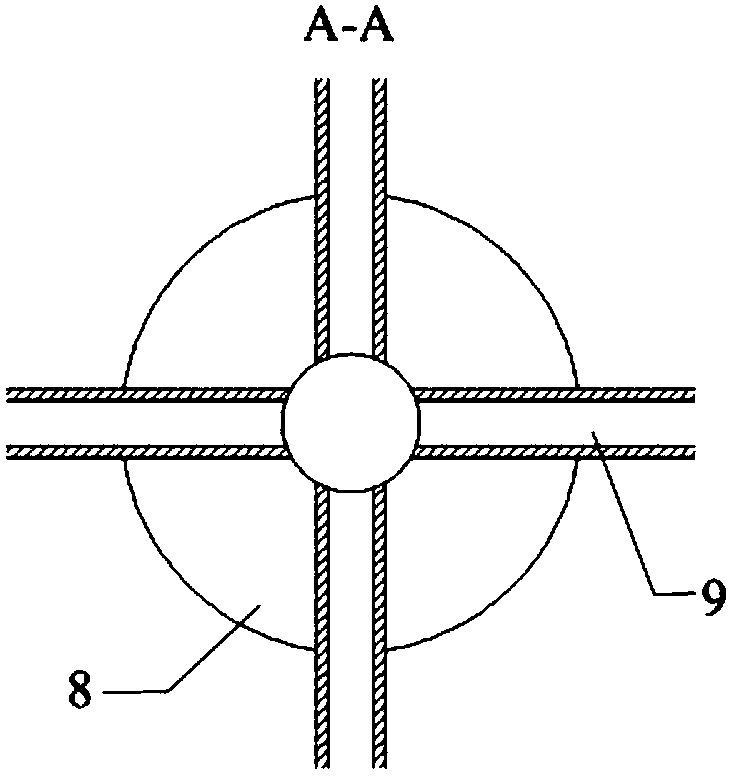

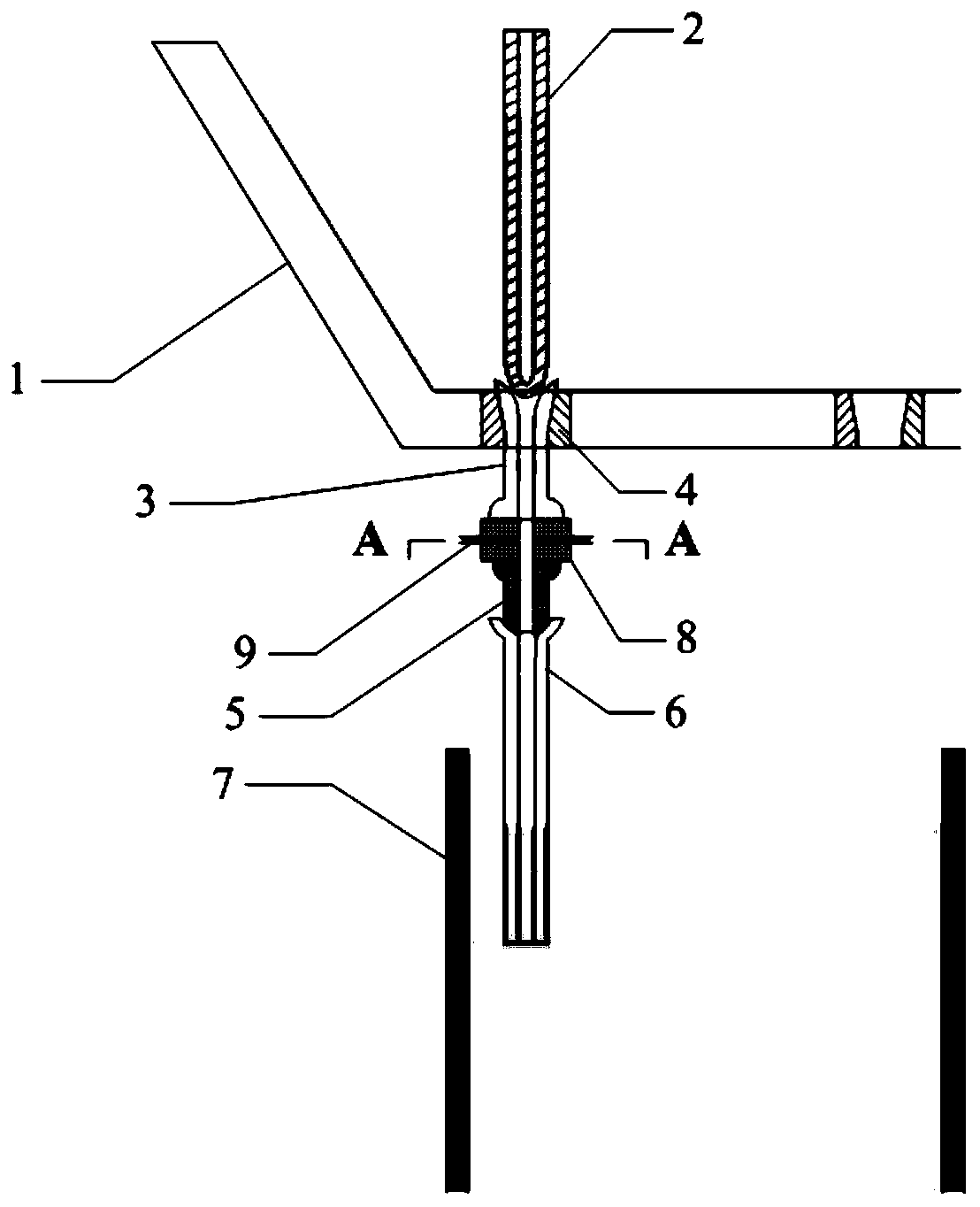

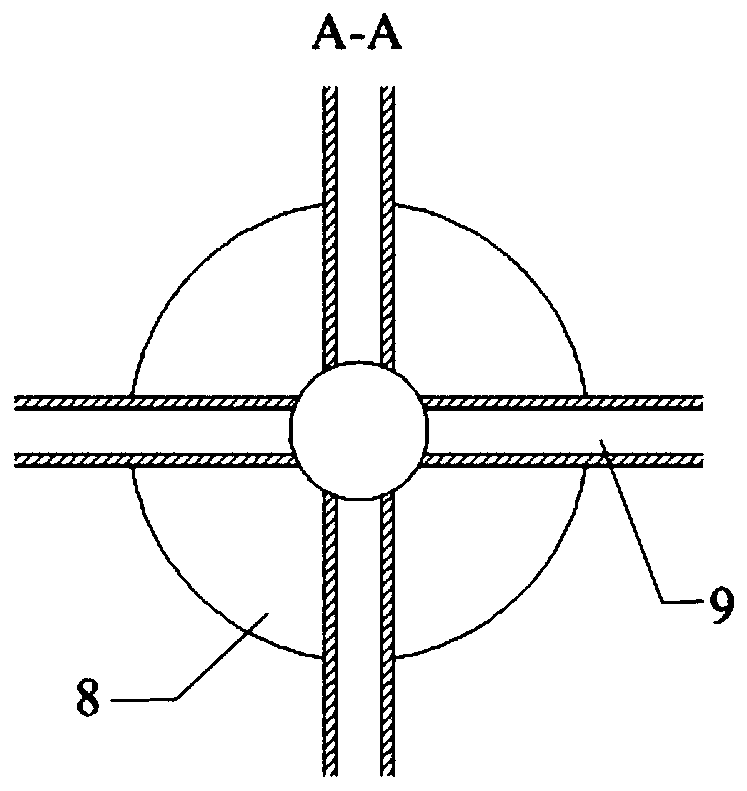

Single-point unbalanced protection casting device for ultra-thin large-size aluminum-containing steel profiled blank and using method thereof

The invention discloses a single-point unbalanced protection casting device for an ultra-thin large-size aluminum-containing steel profiled blank and a using method thereof, and belongs to the technical field of near-net shape continuous casting in the iron and steel metallurgy industry. The single-point unbalanced protection casting device comprises a tundish, a stopper rod, an upper nozzle, a seat brick, a lower nozzle, a submerged nozzle and an H-shaped blank crystallizer; the stopper rod is arranged at an outlet of the tundish; the outlet of the tundish is provided with the upper nozzle and is fixed by the seat brick; the lower end of the upper nozzle is connected with the lower nozzle; the lower end of the lower nozzle is connected with the submerged nozzle; and the submerged nozzle is positioned at the center of a triangular area of a lateral flange of the H-shaped blank crystallizer. The single-point unbalanced protection casting device further comprises a hollow blowing sleevearranged between the upper nozzle and the lower nozzle; the upper nozzle, the sleeve and the lower nozzle form a steel flow channel; the sleeve is provided with air inlets; the number of the air inlets is more than one; and the air inlets communicate with steel flow channel. The quality of a special-shaped blank product can be improved, the yield of casting blanks is increased, the competitivenessof the product in the market is improved, and the single-point unbalanced protection casting device has the advantages of reasonable design and easiness in application.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

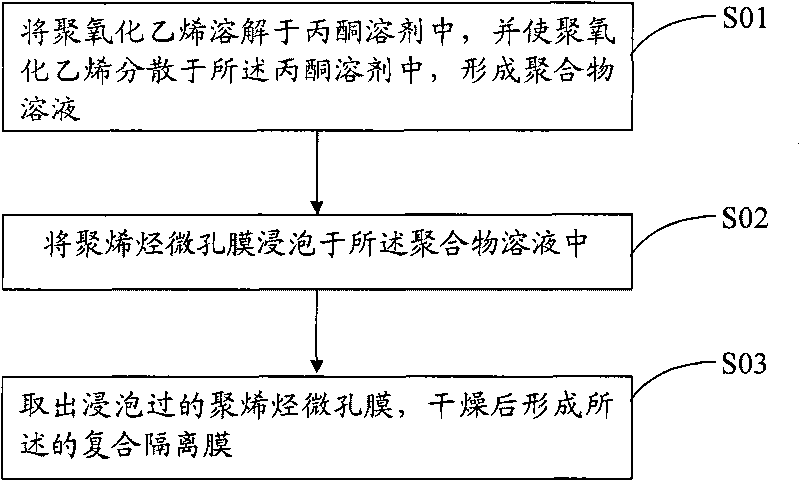

Compound isolating film and formation method thereof

InactiveCN101702426AImprove liquid absorption capacityExcellent ion permeabilityCell component detailsPolyolefinPolymer science

The invention provides a compound isolating film and a formation method thereof. The method comprises the following steps of: dissolving polyethylene glycol oxide in an acetone solvent; dispersing the polyethylene glycol oxide in the acetone solvent to form a polymer solution; soaking a polyolefine microporous film in the polymer solution; taking out the soaked polyolefine microporous film; and drying the polyolefine microporous film to form the compound isolating film. In the method, the acetone solvent is used for compounding the polyethylene glycol oxide and the polyolefine microporous film; and the polyolefine microporous film is modified to obviously enhance the solution absorption capability and the ion penetrating capability of the isolating film. Moreover, the acetone solvent has low price and does not have harm basically, and therefore, the production cost is reduced and the production operating safety is enhanced.

Owner:SHENZHEN SENIOR TECH MATERIAL

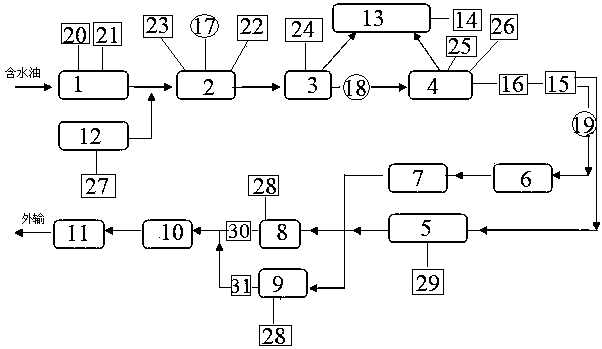

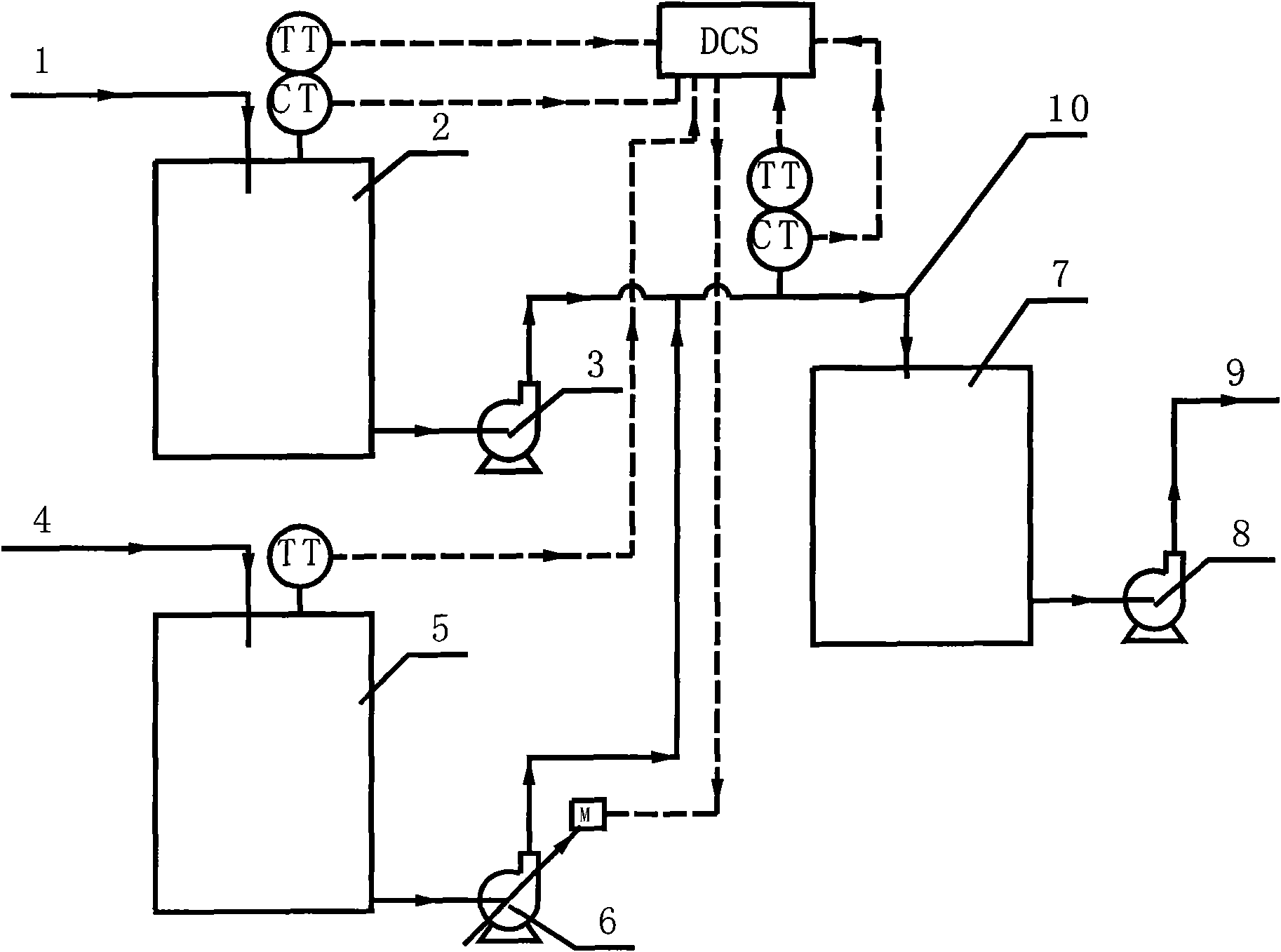

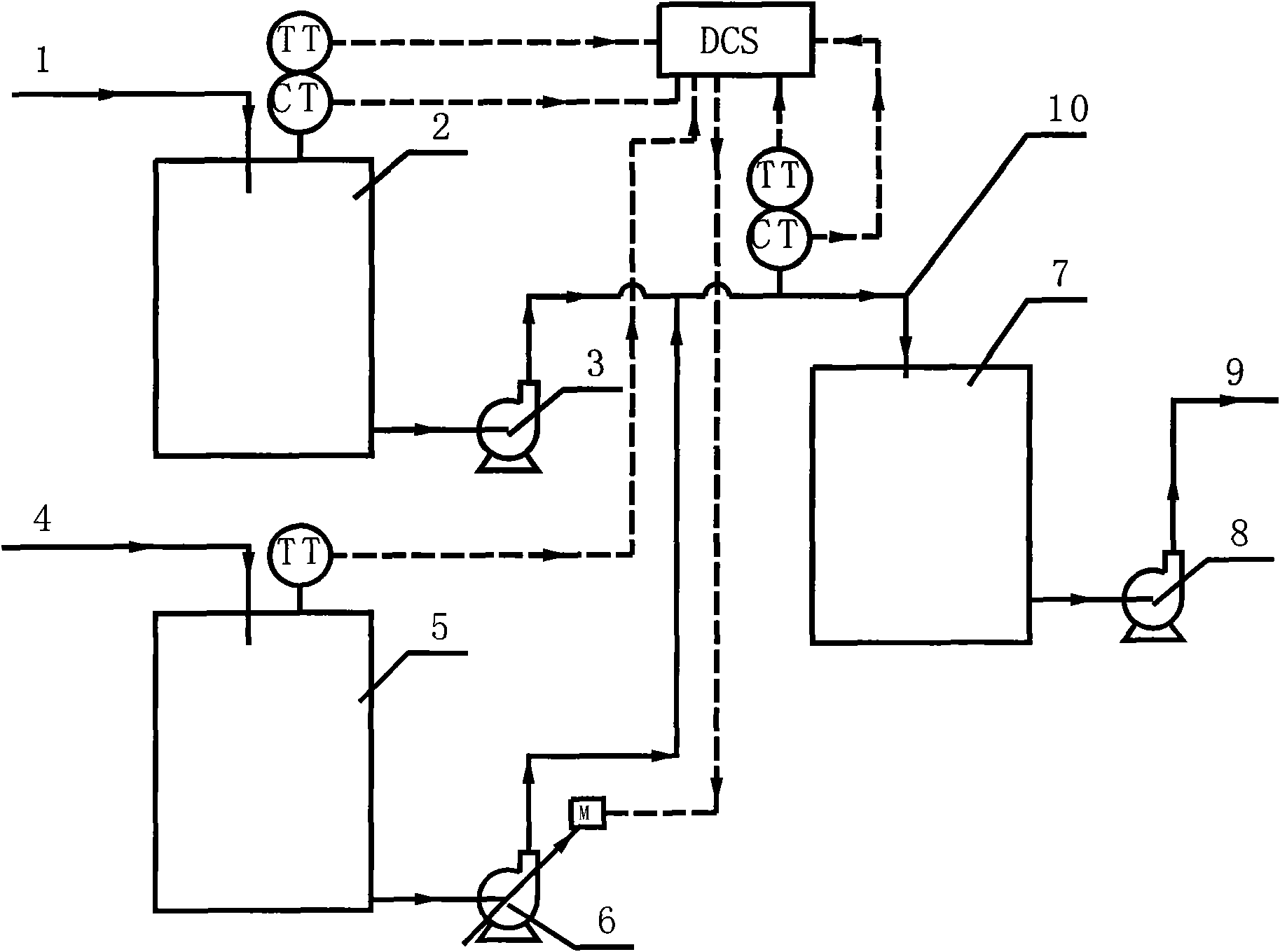

Oil field two-stage dehydration system and method

PendingCN111073682AThe result is accurateSimple processDewatering/demulsification with chemical meansDewatering/demulsification with mechanical meansElectric controlOperation safety

The invention provides an oil field two-stage dehydration treatment system and method. The system comprises a control cabinet and a two-stage dehydration device, the two-stage dehydration device comprises a temperature sensor, a liquid level meter, a pressure sensor and an electric control part, wherein the temperature sensor, the liquid level meter, the pressure sensor and the electric control part are all electrically connected with the control cabinet, and the control cabinet is used for giving an alarm according to temperature, pressure and liquid level signals and controlling starting andstopping of the electric control part. The pressure transmitter and the temperature transmitter are arranged on the ball receiving barrel, so that the safety of a station yard and equipment are protected; a liquid level meter is added to the dosing device, and dosing time is mastered at any time; the first heating furnace is provided with a full-automatic combustor, so that remote automatic ignition and flameout protection are achieved, and the production operation safety of station personnel is improved; an associated gas outlet pressure remote transmission function is added to the buffer tank, and pressure remote transmission, over-limit alarm pump stopping, remote switching of the two pumps and emergency shutdown functions are added to the output pump, so that the number of times of on-site manual operation is reduced; meanwhile, a double-proportion drain valve is additionally arranged at the outlet of the associated gas separator to realize automatic drainage.

Owner:XIAN CHANGQING TECH ENG +1

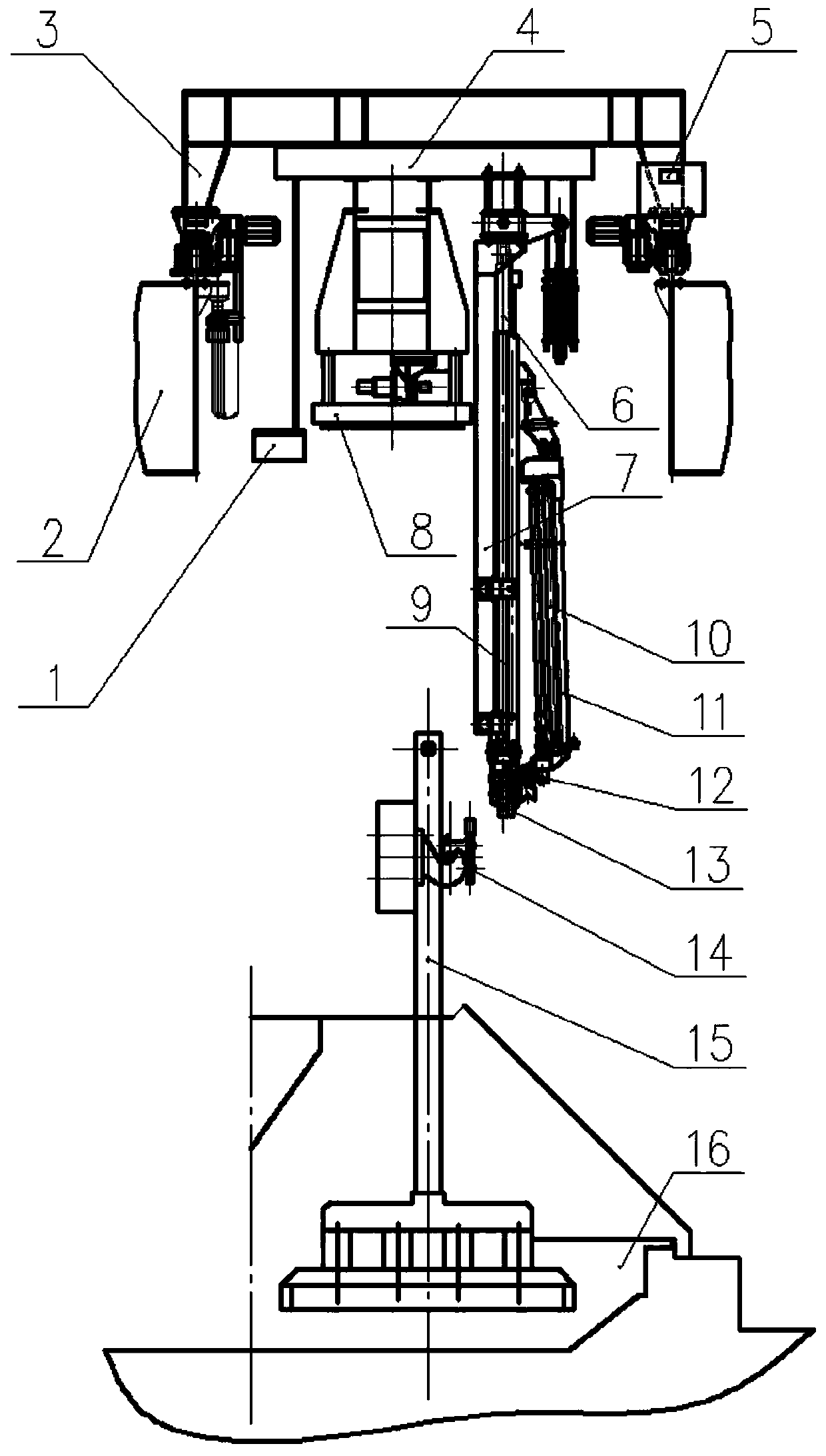

Multifunctional unit intelligent twisting and pulling device and method for aluminum electrolysis

The invention discloses a multifunctional unit intelligent twisting and pulling device and method for aluminum electrolysis. The multifunctional unit intelligent twisting and pulling device comprisesa unit cart device running on an aluminum electrolysis plant warehouse track, tracks on two girders of the unit cart device are provided with a trolley device, and the trolley device is provided witha tool swing mechanism. The cart device, the trolley device and the tool swing mechanism are provided with automatic running and positioning systems. The tool swing mechanism provided with a hydraulicsystem, a measuring and positioning device and a fixing guiding frame. The fixing guiding frame is provided with a lifting servo hydraulic cylinder used for driving an anode lifting frame device anda fixture twisting head frame device to move up and down; and the anode lifting frame device is provided with a twisting head frame servo oil cylinder used for driving the fixture twisting head framedevice and a fixture twisting head to move up and down. By adopting the technical scheme, the anode changing operation efficiency can be improved, the manual operation time is shortened, the labor intensity is relieved, and the production operation safety is improved.

Owner:GUIYANG AL-MG DESIGN & RES INST

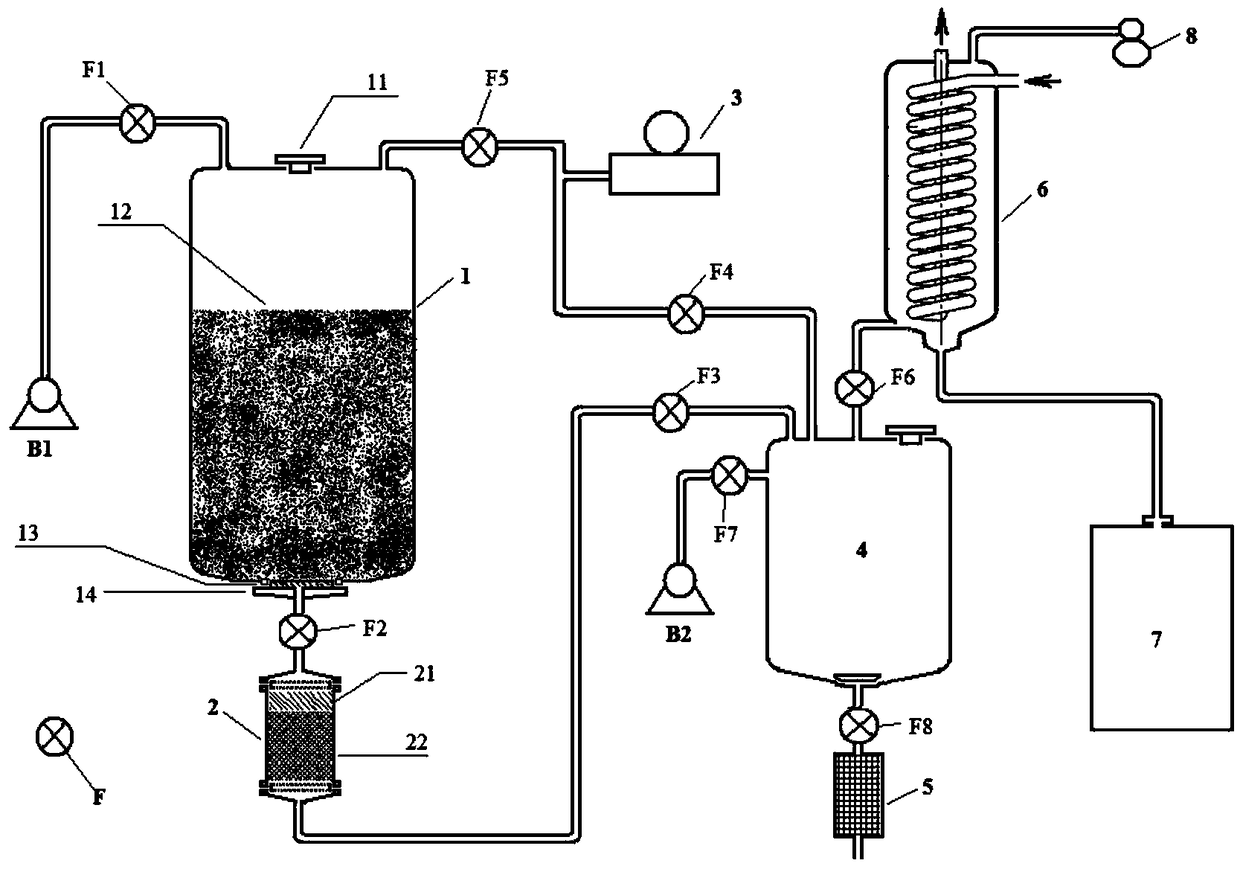

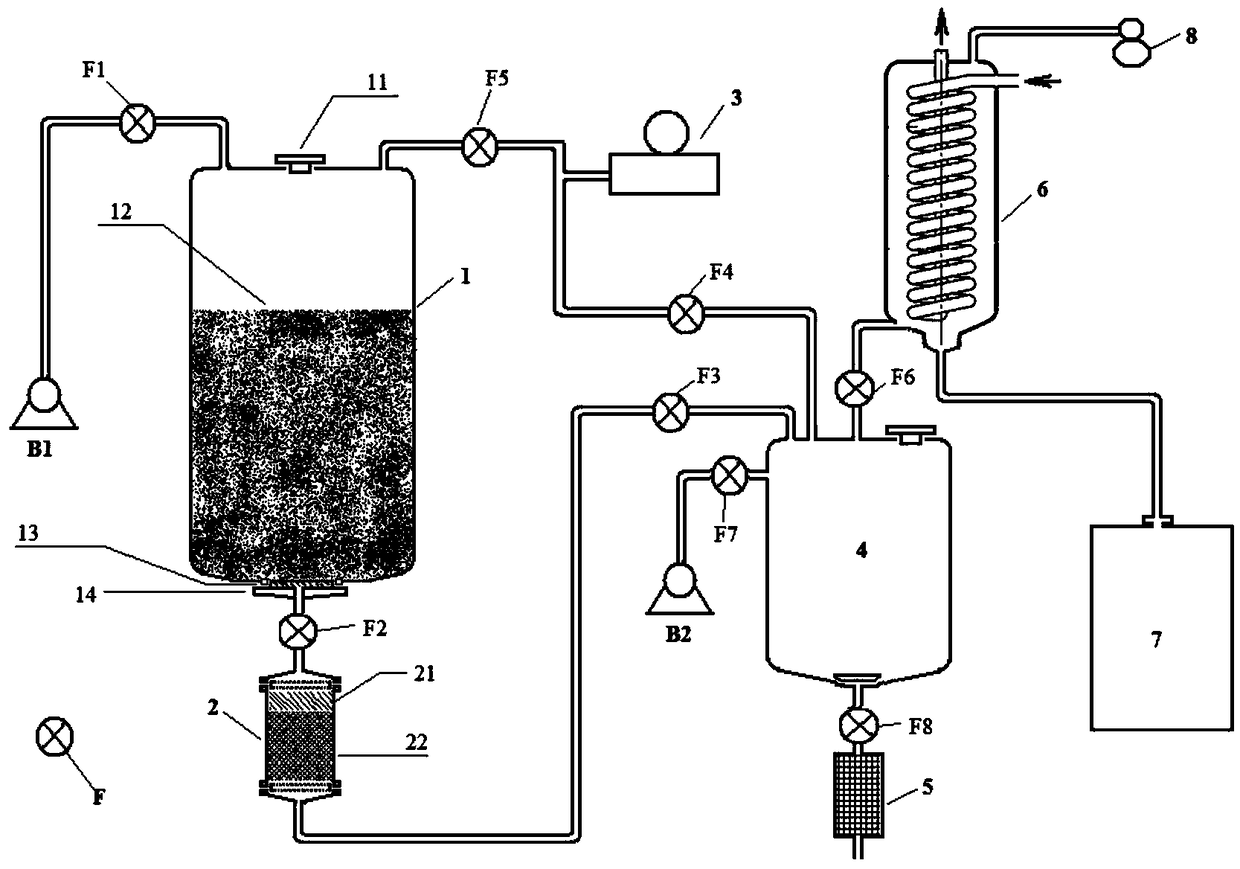

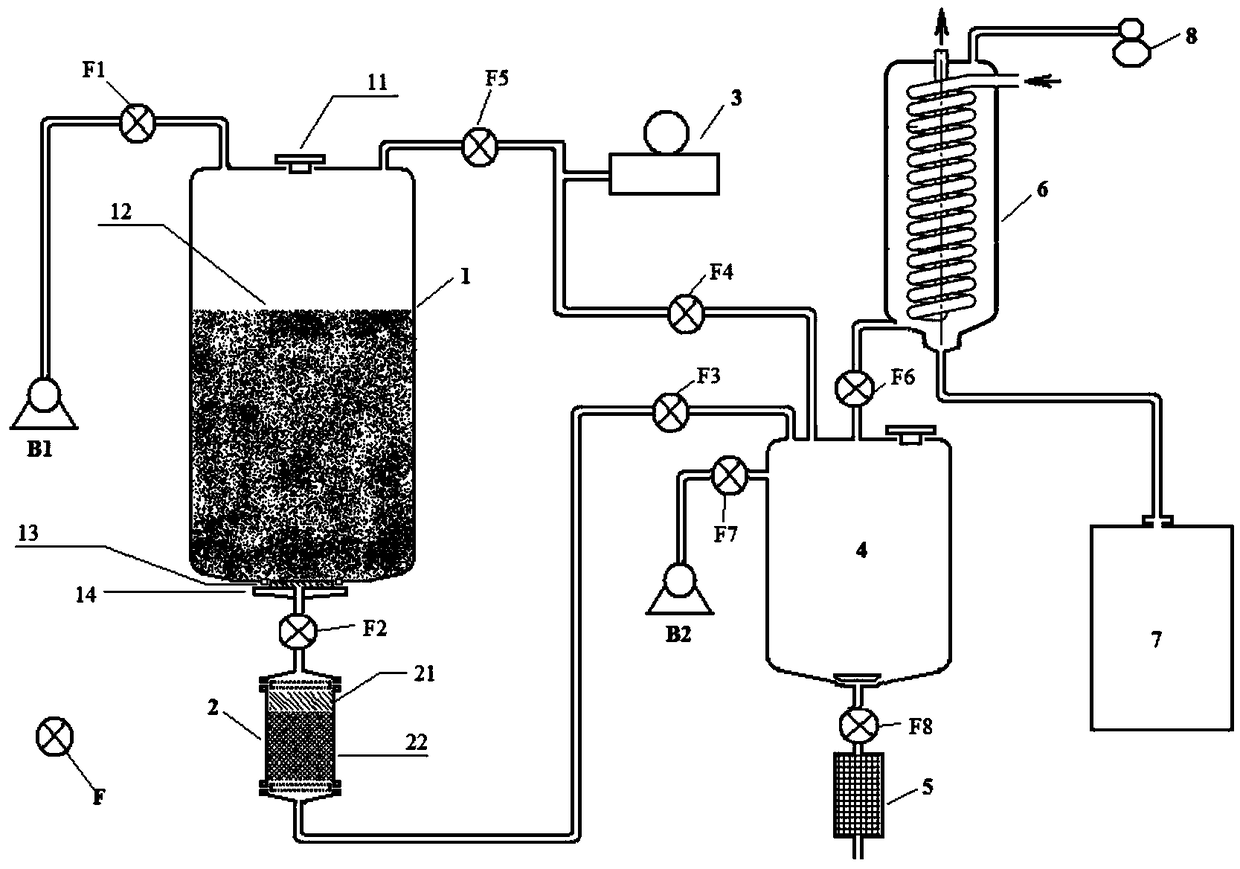

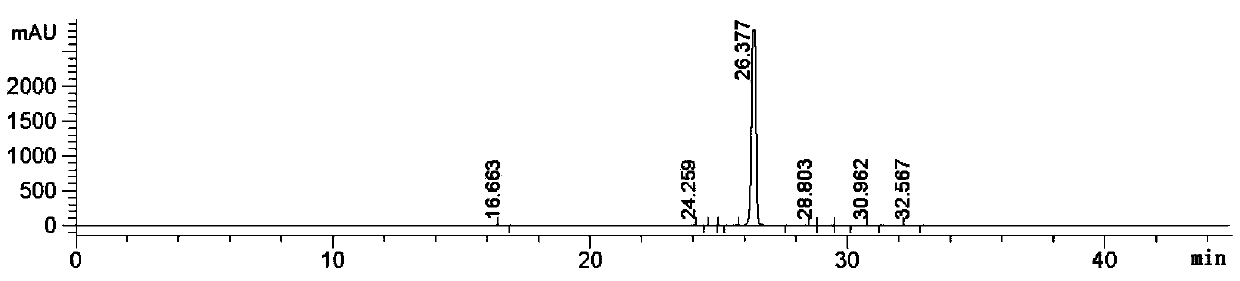

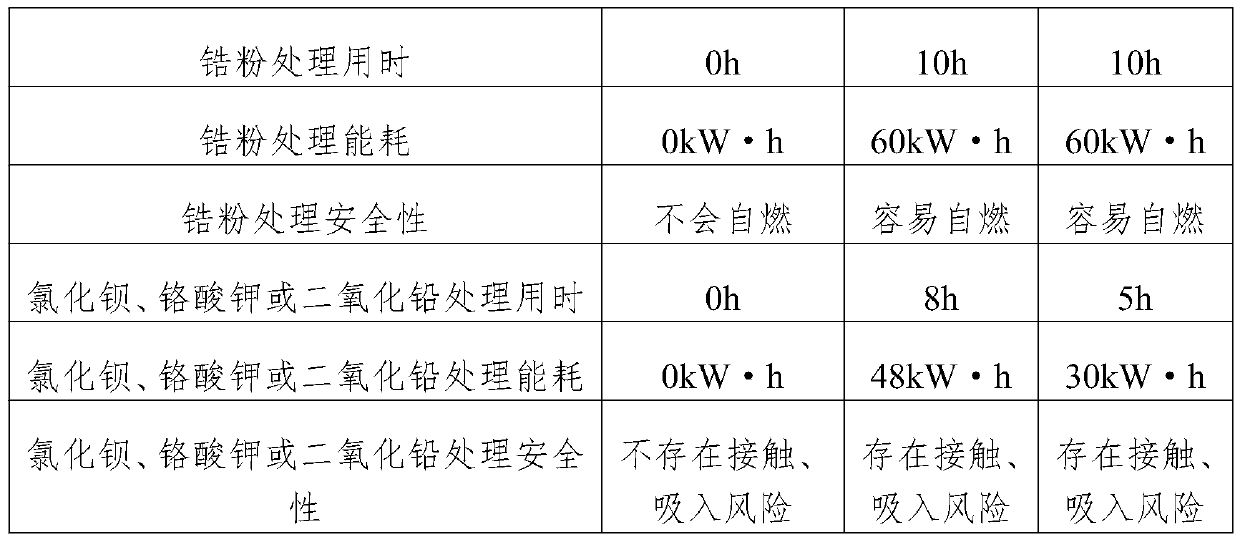

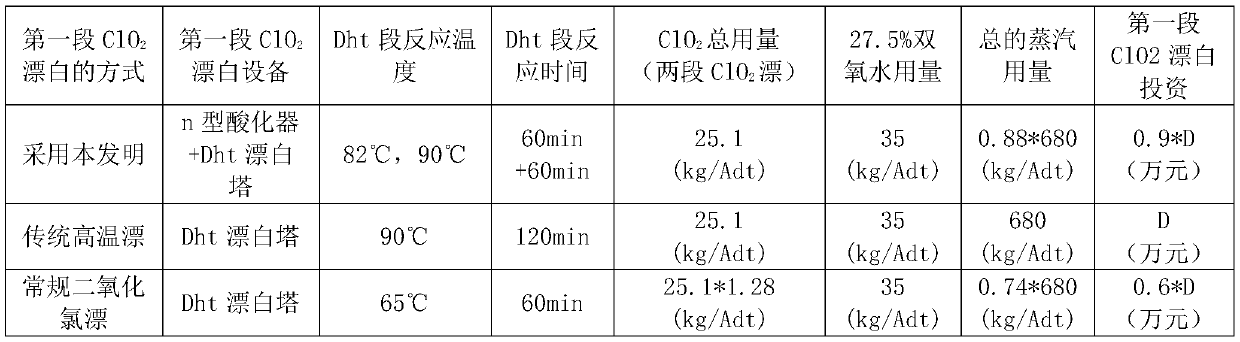

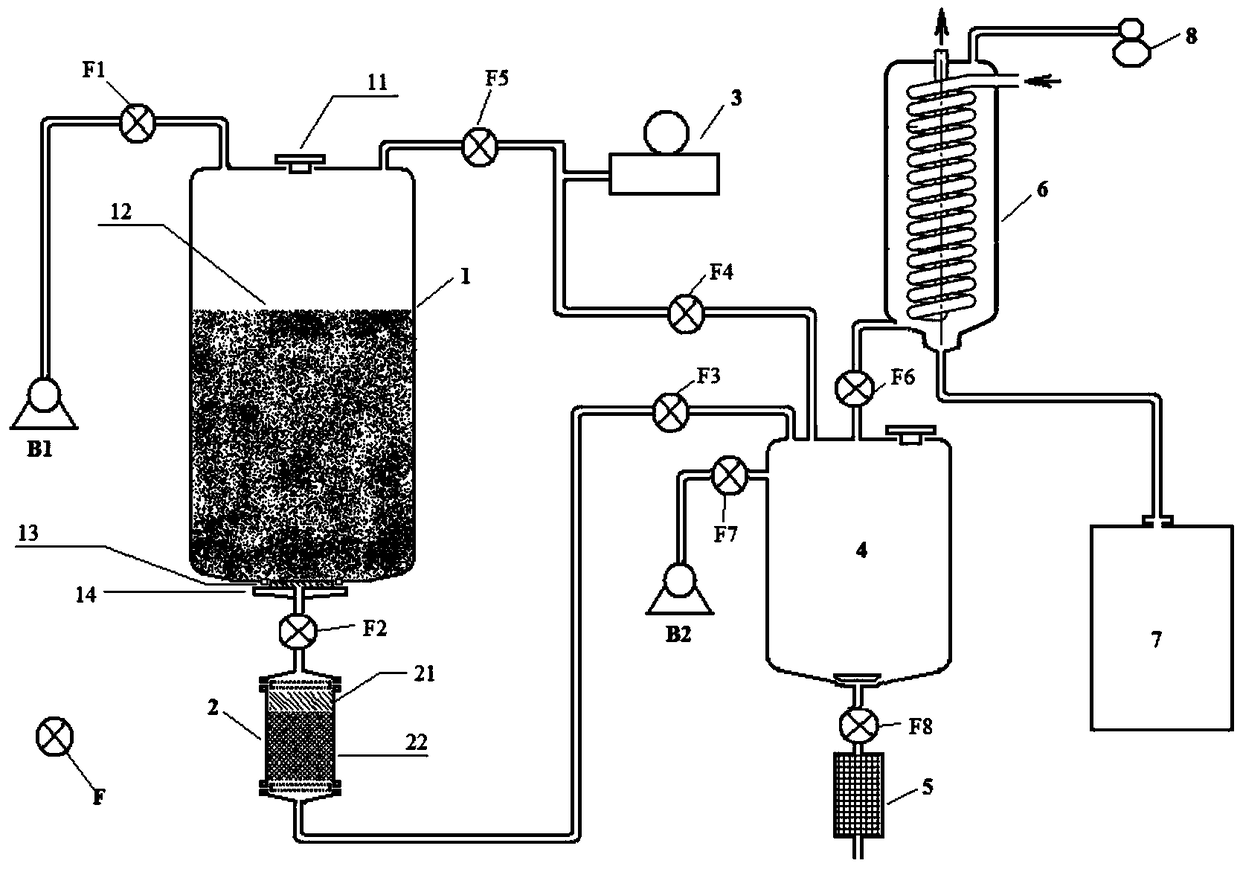

Highly-efficient preparation method and application for tobacco absolute oil

ActiveCN109280581AReduce manufacturing costImprove yield and qualityEssential-oils/perfumesSolventChromatography column

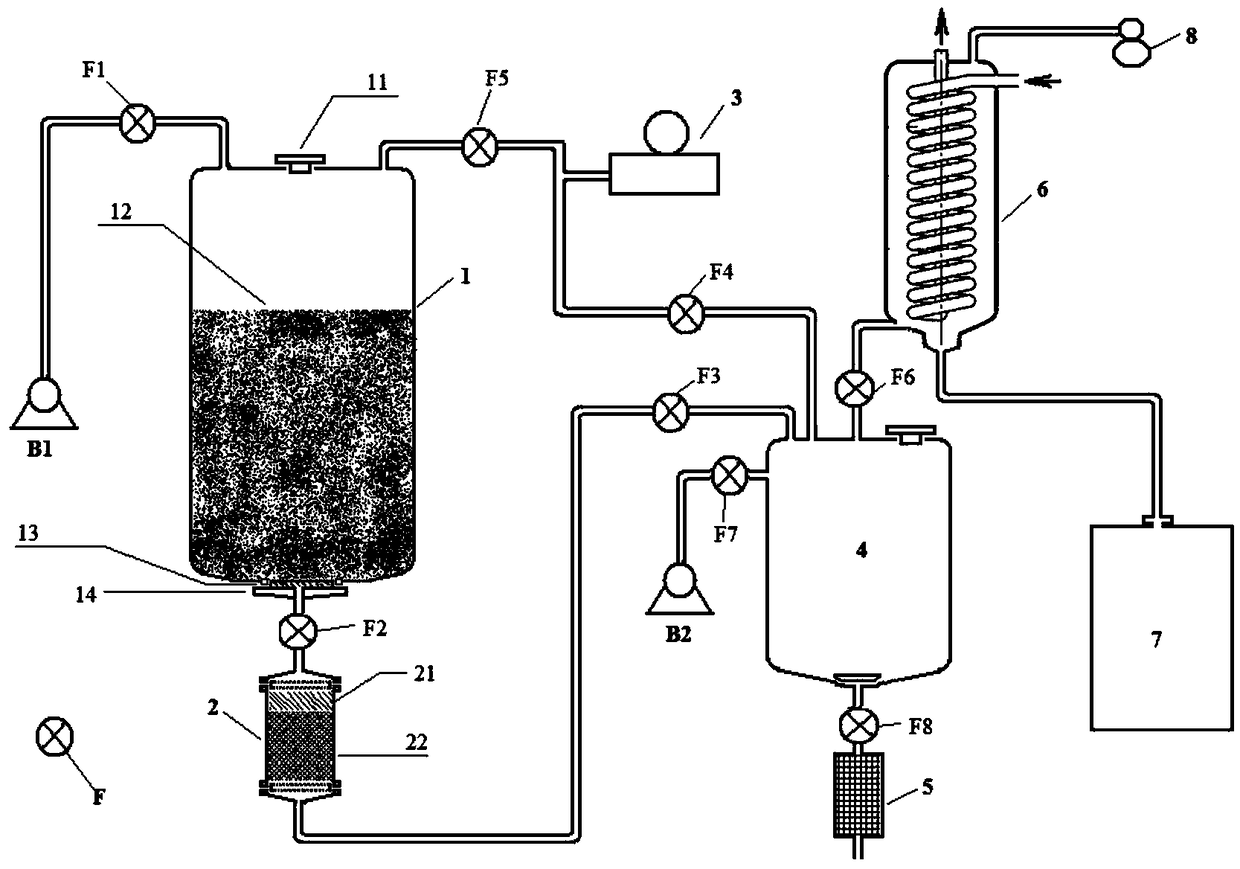

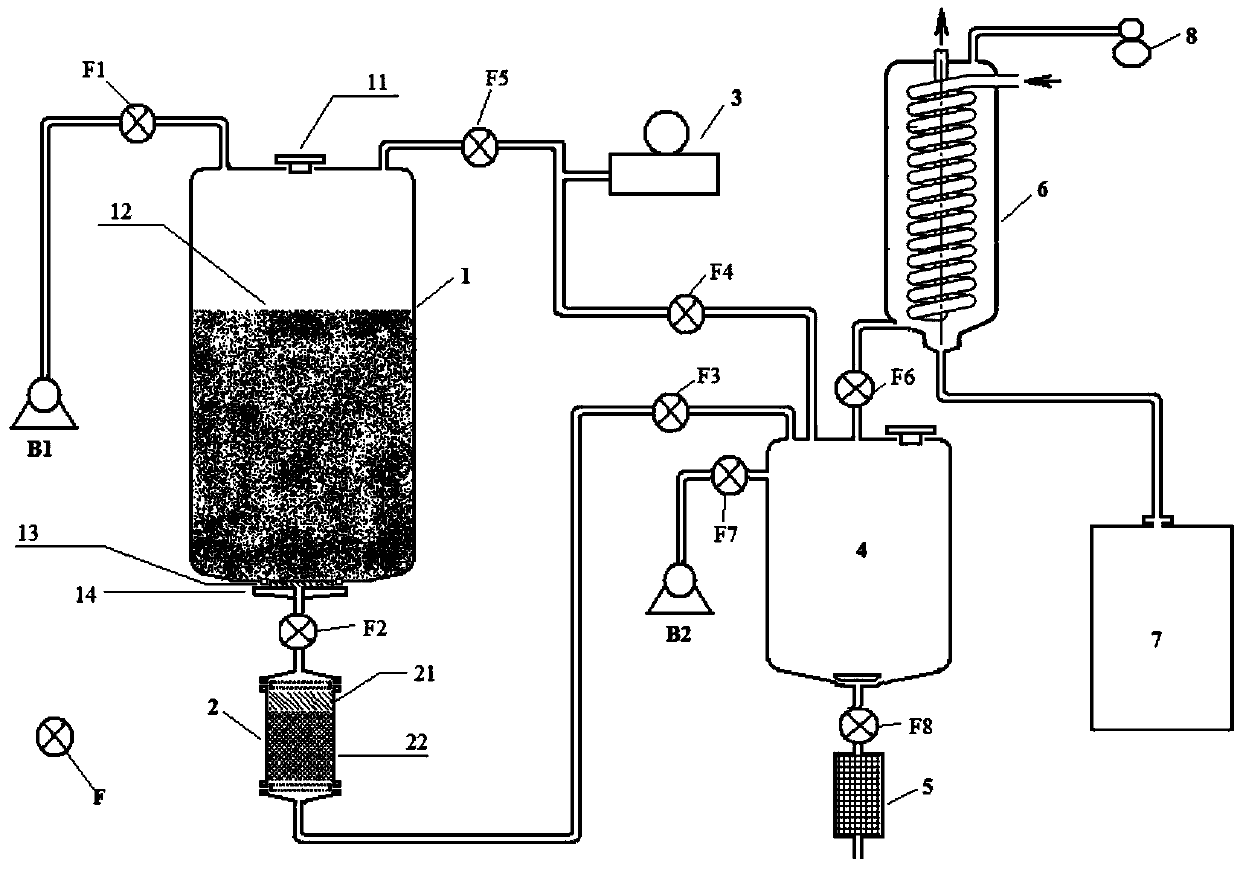

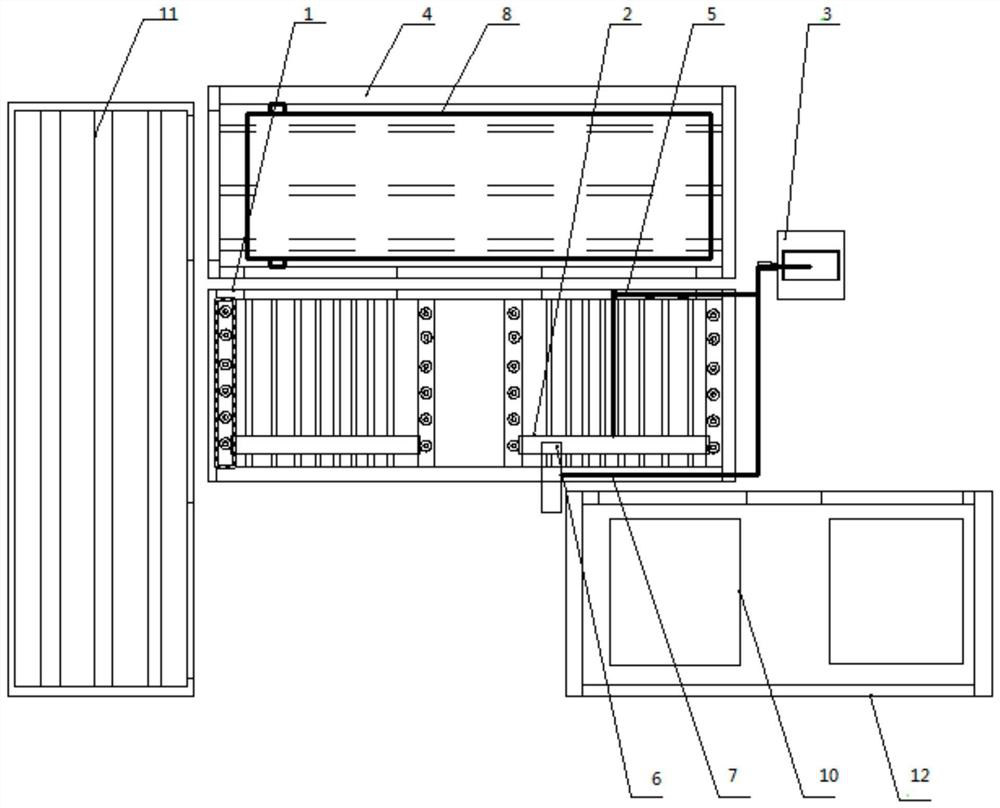

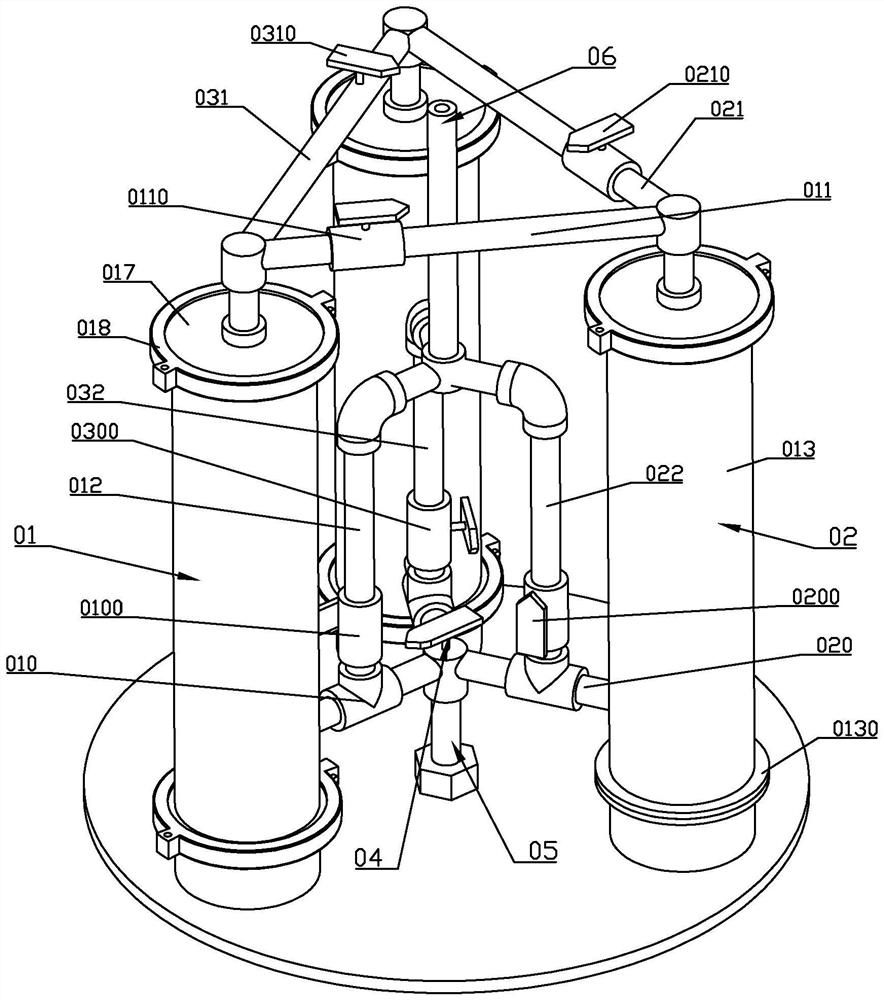

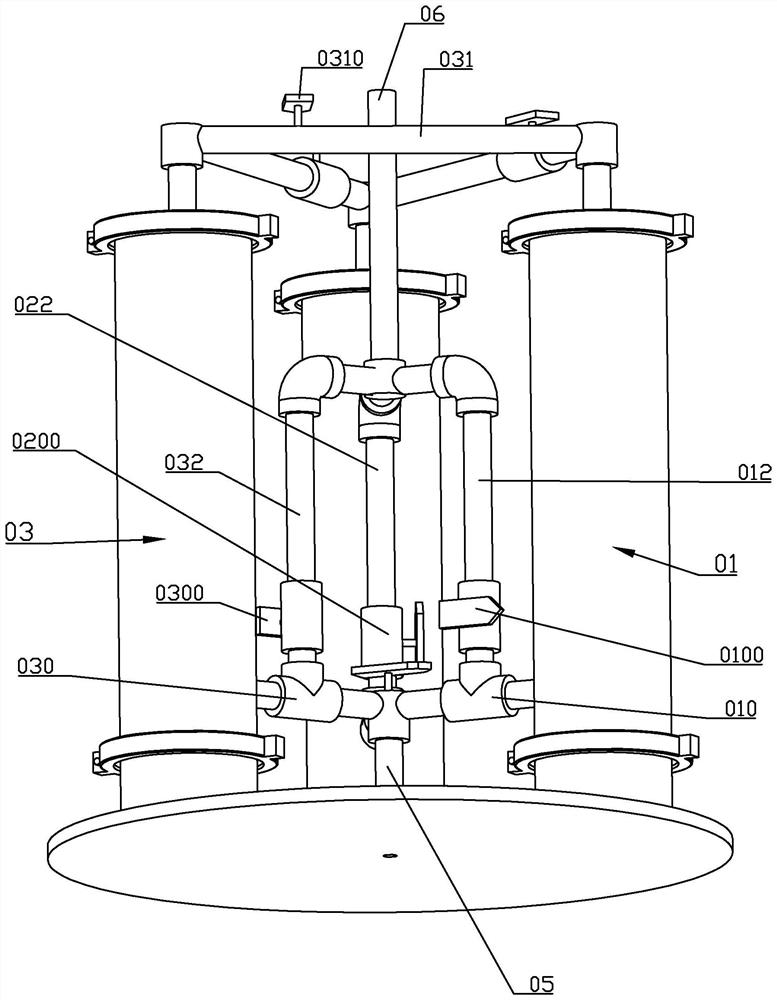

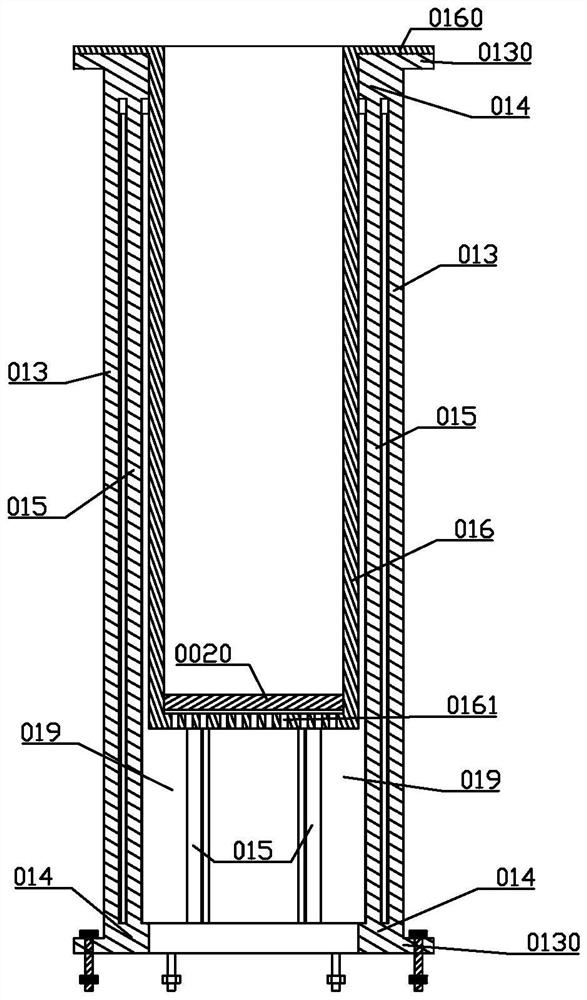

The invention discloses a preparation method for tobacco absolute oil. The preparation method is performed with the following devices: an ultrasonic extraction tank (1), a chromatography column (2), an air compressor (3), a concentration tank (4), a reverse resin column (5), a condenser (6), a vacuum pump (8) and a solvent recovery tank (7). The preparation method comprises the following steps: 1,subjecting a tobacco raw material to ultrasonic extraction; 2, carrying out purification through the chromatography column (2); 3, carrying out concentration; 4, carrying out purification through thereverse resin column ( 5); and 5, carrying out decompressing to remove ethanol so as to obtain the tobacco absolute oil. The devices provided by the invention can realize highly-efficient extractionand purification of the tobacco absolute oil; and the tobacco absolute oil obtained by using the preparation method provided by the invention is used in cigarettes, electronic cigarettes or heat-not-burn cigarettes, and effectively enhances and improves the suction comfort of the cigarettes, the electronic cigarettes and the heat-not-burn cigarettes.

Owner:CHINA TOBACCO YUNNAN IND

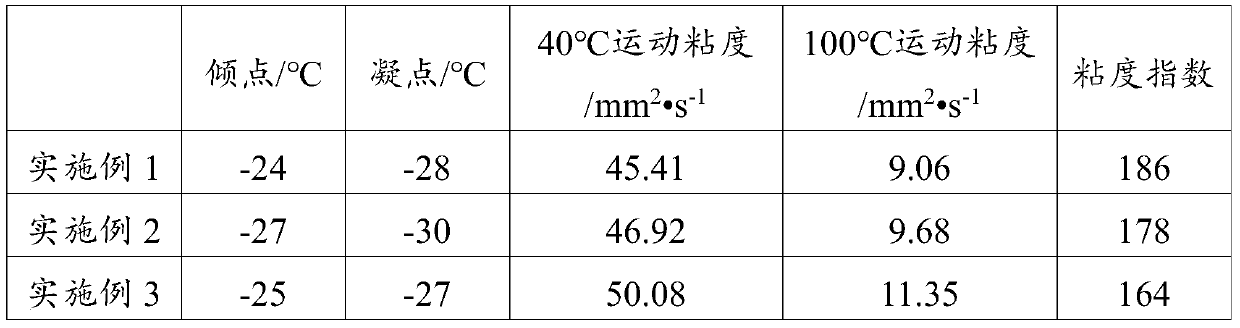

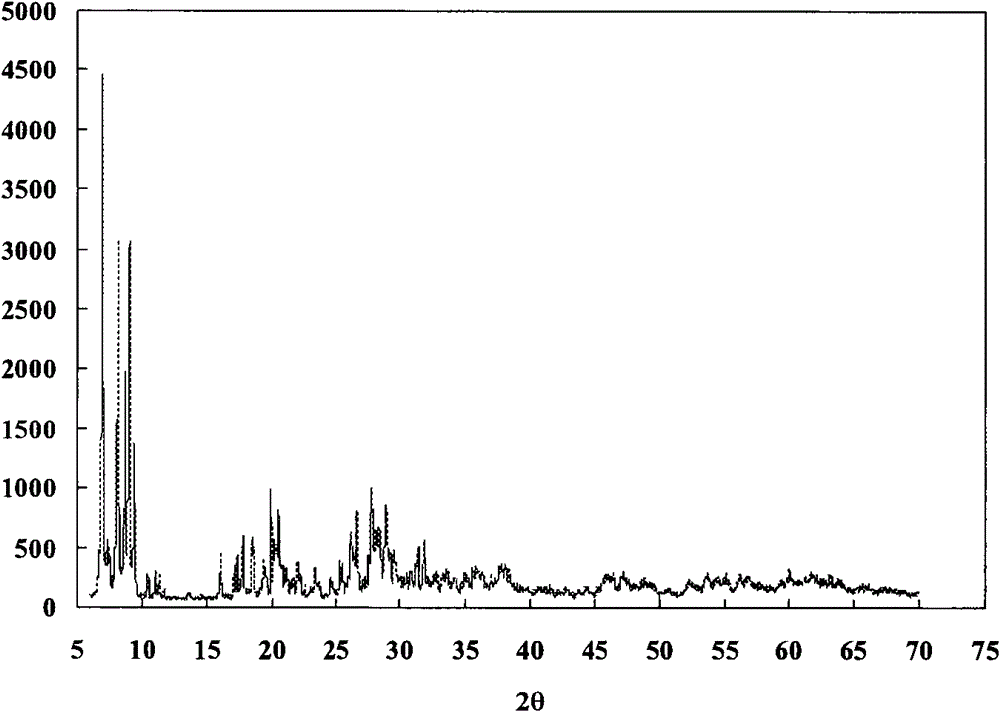

Method for producing fully synthetic lubricating oil from grease

InactiveCN110240937AWide variety of sourcesReduce usageLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesOil and greasePolyolefin

The invention provides a method for producing fully synthetic lubricating oil by using grease as a raw material and by means of three steps of reactions. The method comprises the following steps: 1, deoxidizing the grease under the hydrogen-free condition until long-chain alkenes are obtained; 2, carrying out polymerization on the long-chain alkenes to obtain polyolefin; 3, carrying out hydrogenation on the polyolefin to obtain base oil of the fully synthetic lubricating oil; adding additives and the like into the base oil to prepare the high performance fully synthetic lubricating oil. The method provided by the invention is simple in process; the selected raw material grease comprises non-edible oil or waste catering oil, so that the raw material source is wide, the use of raw materials from fossil energy sources is avoided, and environmental pollution is reduced while the cost is lowered. The product is comb-shaped regular saturated hydrocarbon molecules containing no oxygen, has excellent properties comparable to those of polyamine oxidase (PAO), and is suitable for being used in various harsh conditions.

Owner:EAST CHINA NORMAL UNIV

Preparation method of phosphotungstic heteropoly acid

ActiveCN102744088BImprove the safety of production operationsPhysical/chemical process catalystsHydrogen phosphateOrganic solvent

The invention relates to a preparation method of silicotungstic heteropoly acid, and aims to mainly solve the problem that employment of inflammable low-boiling point organic extracting agent can result in poor production security in the prior art. The method of the invention includes the following steps of: a) dissolving sodium tungstate and sodium hydrogen phosphate in water to generate a mixed solution of phosphotungstic acid and sodium phosphotungstate under heating and acidic conditions, with the sodium tungstate and the sodium hydrogen phosphate in a weight ratio of 1:0.1-1:10; b) dissolving CnH2n+1N<+>Cl<-> in an organic solvent to obtain an organic solution of CnH2n+1N<+>Cl<->, wherein n is a positive integer from 10 to 30, and with the sodium tungstate adding amount as the reference, the adding amount of CnH2n+1N<+>Cl<-> content is 0.01-1 mol / g sodium tungstate; and c) adding the organic solution of CnH2n+1N<+>Cl<-> into the mixed solution of phosphotungstic acid and sodium phosphotungstate for reaction, then carrying out centrifugation, washing, drying and roasting on the product, thus obtaining silicotungstic heteropoly acid. The technical scheme in the method of the invention well solves the problem, and can be used in the industrial production of silicotungstic heteropoly acid.

Owner:CHINA PETROLEUM & CHEM CORP +1

Effective preparation method and application of coffee purified oil

ActiveCN109090700AHigh yieldImprove qualityTobacco preparationTobacco treatmentElectronic cigaretteAir compressor

The invention discloses a preparation method of coffee purified oil. The following devices are used: an ultrasonic extraction tank (1), a chromatographic column (2), an air compressor (3), a concentrating tank (4), a reverse resin column (5), a condenser (6), a vacuum pump (8) and a solvent recycling tank (7). The preparation method comprises the following steps: (1) ultrasonically extracting coffee raw materials; (2) purifying through the chromatographic column (2); (3) concentrating; (4) purifying through the reverse resin column (5); and (5) removing ethanol under reduced pressure to obtainthe coffee purified oil. The coffee purified oil can be effectively extracted and purified by the device, the obtained coffee purified oil is used for cigarettes, electronic cigarettes or cigarettesnot combusting after being heated, and the smoking comfort level is effectively improved.

Owner:CHINA TOBACCO YUNNAN IND

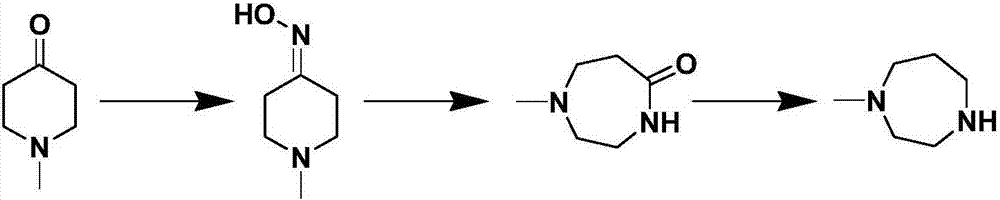

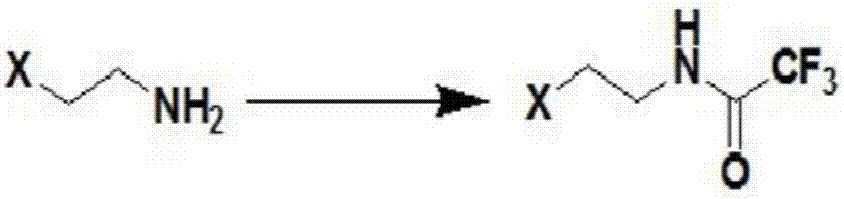

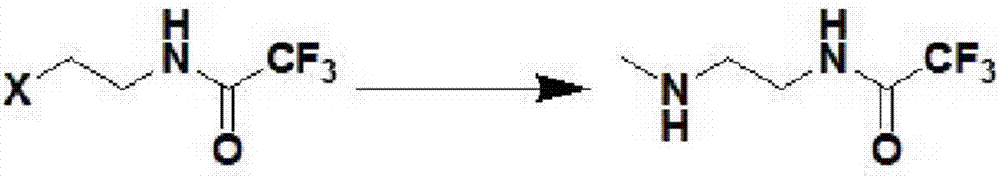

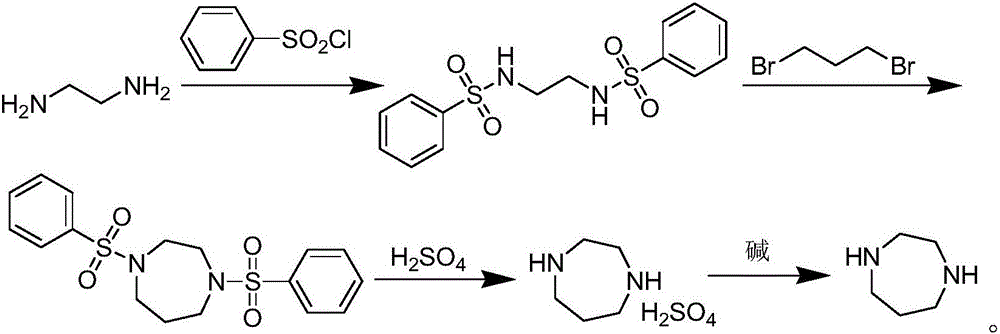

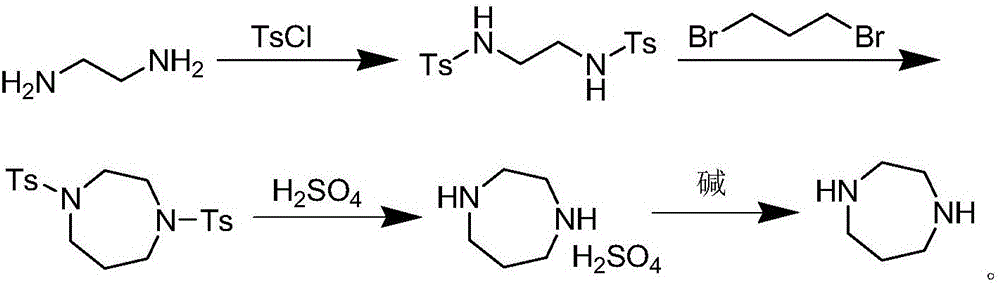

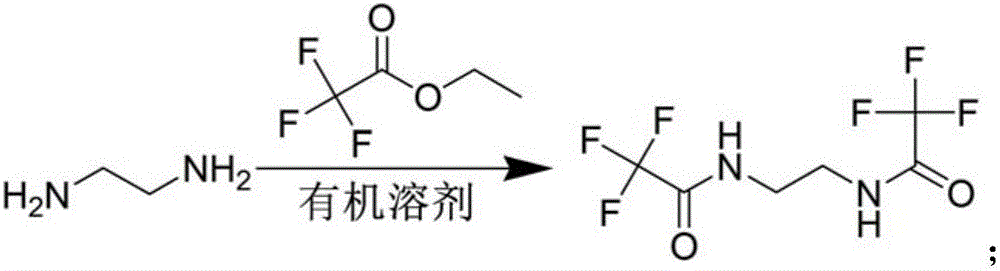

Process for preparing N-methyl homopiperazine from 2-haloethylamine compound

InactiveCN107382883AHigh degree of environmental protectionImprove the safety of production operationsOrganic chemistryEthylenediamineTrifluoroacetic acid

The invention discloses a process for preparing N-methyl homopiperazine from 2-haloethylamine compound, and the process comprises the following steps: Step 1, taking the 2-halogenated ethylamine compound as a raw materia to react with ethyl trifluoroacetate to obtain N-(2-Haloethyl) trifluoroacetamide; Step (2) taking the N-(2-Haloethyl) trifluoroacetamide as a raw material to react with methylamine or methylamine hydrochloride to obtain N-methyl-N'-trifluoroacetyl ethylenediamine; Step (3) taking the N-methyl-N'-trifluoroacetyl ethylenediamine as a raw material to react with 1,3-disubstituted propane compound to obtain N-methyl-N'-trifluoroacetyl homopiperazine; Step (4) taking the N-methyl-N'-trifluoroacetyl homopiperazine as a raw material to react with a hydrogen chloride ethanol solution to obtain N-methyl homopiperazine dihydrochloride; and Step (5) taking the N-methyl homopiperazine dihydrochloride as a raw material to prepare the N-methyl homopiperazine by alkalization. The process has the advantages of simple operation, low cost, high yield, low pollution and suitability for industrialized production.

Owner:SUZHOU BAILINGWEI HYPERFINE MATERIAL

High-efficient preparation method and application of red jujube purified oil

ActiveCN109123754AHigh yieldImprove qualityTobacco preparationTobacco treatmentElectronic cigaretteSolvent

The invention discloses a preparation method of red jujube clean oil, which uses the following devices: an ultrasonic extraction tank (1); a chromatographic column (2); an air compressor (3); a thickening tank (4); a reverse resin column (5); a condenser (6); a vacuum pump (8); a solvent recovery tank (7). The method includes the steps of (1) ultrasonic extraction of red jujube raw material; (2),purifying by chromatographic column; (3); concentration; (4) purifying by a reverse resin column; (5) removing ethanol under reduced pressure to obtain the pure red jujube oil. The device of the invention can efficiently extract and purify the red jujube clean oil, and the obtained red jujube clean oil can be used in cigarette, electronic cigarette or heated non-combustible cigarette, so as to effectively improve and improve the smoking comfort of the cigarette.

Owner:CHINA TOBACCO YUNNAN IND

System and method for preparing alkaline water used for preparing flocculating agent

InactiveCN101885524AShorten the conveying distanceReduce consumptionWater/sewage treatment by flocculation/precipitationHigh concentrationRed mud

The invention discloses the preparation of alkaline water and particularly relates to a system and a method for preparing alkaline water used for preparing a flocculating agent for use in a red mud sedimentation separation and washing process step in an aluminum oxide production process. The system for preparing alkaline water used for preparing the flocculating agent comprises the following structures: a red mud washing liquid tank and a freshwater tank, wherein the red mud washing liquid tank is connected with a qualified alkaline water tank through a combined pipe; and the fresh water tank is connected to the combined pipe through a pipe. The system has the advantages that the substitution of red mud washing liquid for the alkaline liquid eliminates the use of high-concentration alkaline caustic liquid and improves the safety of production operation. The preparation of the alkaline water by using the red mud washing liquid allows for full utilization of the original heat energy of the red mud washing liquid and ensures the temperature can reach a temperature required by qualified alkaline water after the red mud washing liquid is diluted; therefore steam for raising temperature is not required to be added and energy consumption is lowered. The flocculating agent preparation process step is usually performed in a red mud separation and washing area, so as that the preparation of the alkaline water by using the red mud liquid has the advantages of short transport distance and low kinetic energy consumption.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Highly-efficient preparation method for dried orange peel absolute oil for flavoring of tobacco

The invention discloses a preparation method for dried orange peel absolute oil. The preparation method is performed with the following devices: an ultrasonic extraction tank (1), a chromatography column (2), an air compressor (3), a concentration tank (4), a reverse resin column (5), a condenser (6), a vacuum pump (8) and a solvent recovery tank (7). The preparation method comprises the followingsteps: 1, subjecting a dried orange peel raw material to ultrasonic extraction; 2, carrying out purification through the chromatography column (2); 3, carrying out concentration; 4, carrying out purification through the reverse resin column ( 5); and 5, carrying out decompressing to remove ethanol so as to obtain the dried orange peel absolute oil. The devices provided by the invention can realize highly-efficient extraction and purification of the dried orange peel absolute oil; and the dried orange peel absolute oil obtained by using the preparation method provided by the invention is usedin cigarettes, electronic cigarettes or heat-not-burn cigarettes, and effectively enhances and improves the suction comfort of the cigarettes, the electronic cigarettes and the heat-not-burn cigarettes.

Owner:CHINA TOBACCO YUNNAN IND

Method for preparing homopiperazine by utilizing ethyl trifluoroacetate

ActiveCN106699674AHigh degree of environmental protectionImprove the safety of production operationsOrganic chemistrySolventChemistry

The invention discloses a method for preparing homopiperazine by utilizing ethyl trifluoroacetate. The method comprises the following steps: (1) taking ethylenediamine as an initial raw material; enabling the ethylenediamine to react with the ethyl trifluoroacetate under the action of an organic solvent, so as to prepare bistrifluoroacetylethylenediamine; (2) enabling the bistrifluoroacetylethylenediamine obtained by the step (1) to react with a 1,3-disubstituted propane compound under the action of a solvent and a catalyst, so as to obtain bistrifluoroacetyl homopiperazine; (3) enabling the bistrifluoroacetyl homopiperazine obtained by the step (2) to react with a hydrogen chloride ethanol solution to obtain homopiperazine bihydrochloride; recycling the ethyl trifluoroacetate; (4) enabling the homopiperazine bihydrochloride obtained by the step (3) to react with alkali under the action of a solvent and a catalyst, so as to prepare the homopiperazine. The method disclosed by the invention has the beneficial effects of simplicity and convenience for operation, relatively low cost, relatively high yield, relatively small pollution and wide applicable range, and can meet the requirements on industrial production of products.

Owner:SUZHOU BAILINGWEI HYPERFINE MATERIAL

High-efficiency preparation method for rose absolute oil for tobacco flavoring

The invention discloses a preparation method of rose absolute oil. The following devices are used: an ultrasonic extraction tank (1); a chromatography column (2); an air compressor (3); a concentration tank (4); a reverse resin column (5); a condenser (6); a vacuum pump (8); and a solvent recovery tank (7). The method comprises the following steps: 1) performing ultrasonic extraction of a rose rawmaterial; 2) performing purification by the chromatography column (2); 3) performing concentration; 4) performing purification by the reverse resin column (5); and 5) removing ethanol under reduced pressure to obtain the rose absolute oil. The device of the invention can efficiently extract and purify the rose absolute oil, and the obtained rose absolute oil is used in the cigarettes, the electronic cigarettes or the heat-not-burn cigarettes, and can effectively improve the smoking comfort.

Owner:CHINA TOBACCO YUNNAN IND

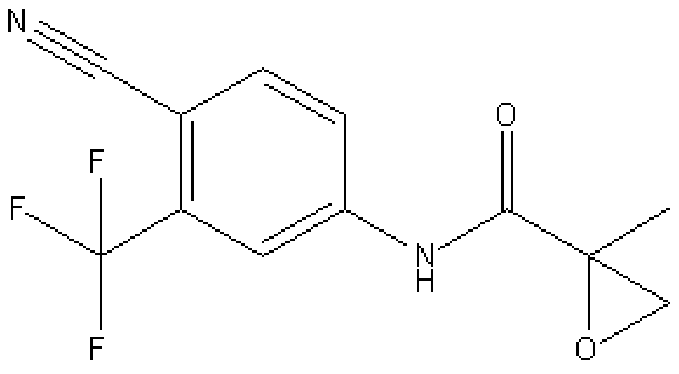

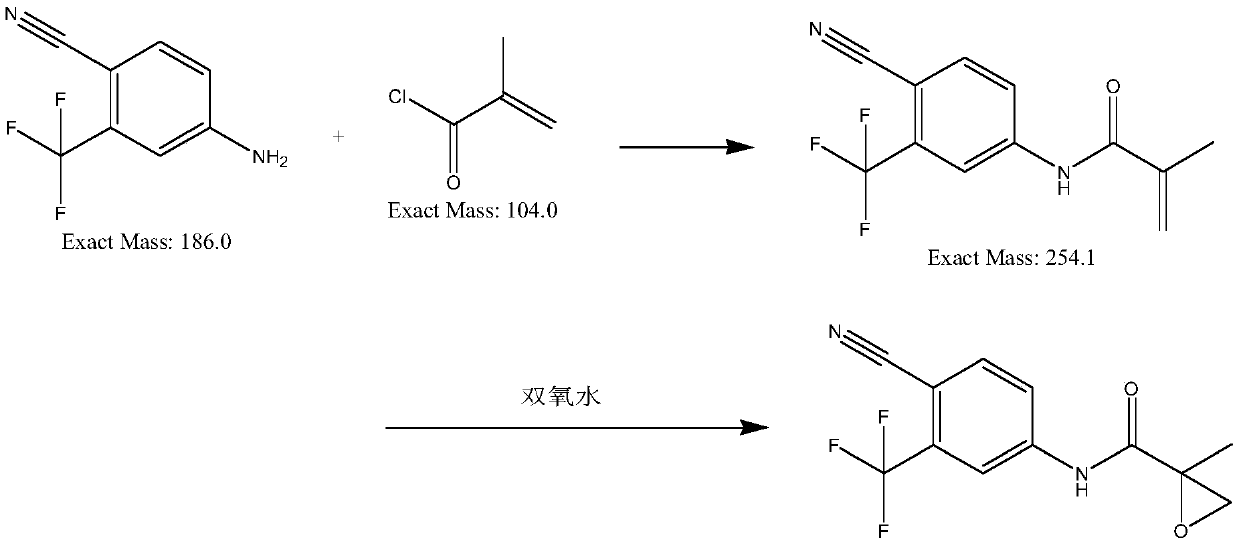

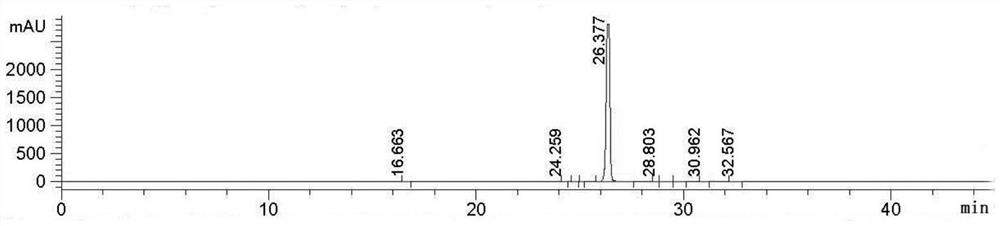

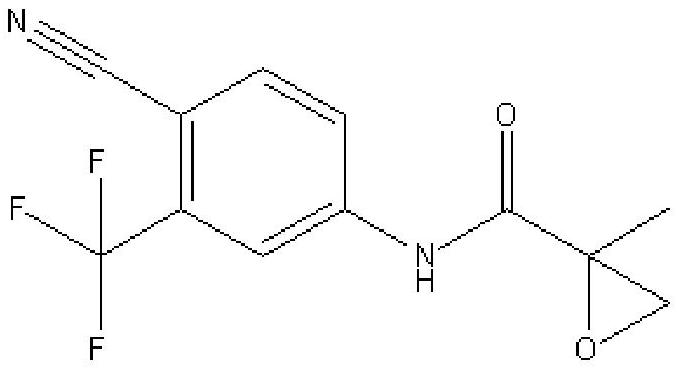

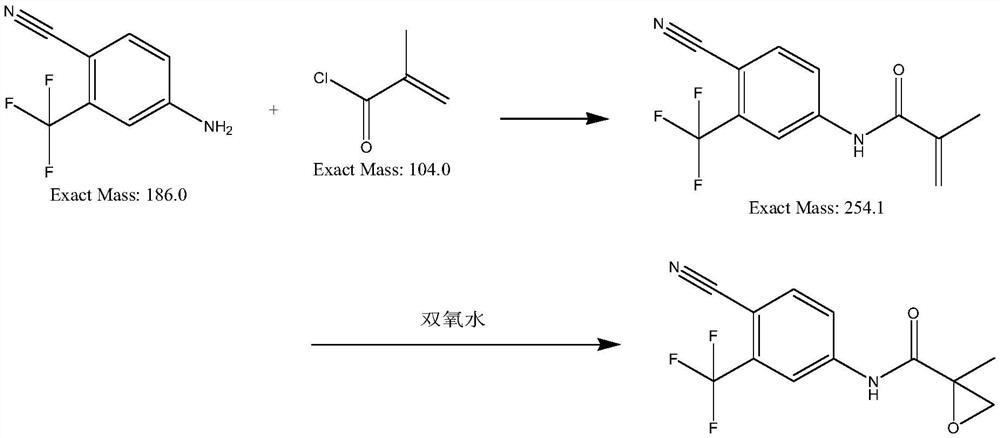

Synthesis method of N-(4-cyano-3-(trifluoromethyl)phenyl)-2-methyl epoxypropylene-2-amide

ActiveCN111087367AMild reaction conditionsImprove the safety of production operationsOrganic chemistryPtru catalystMethacrylate methyl

The invention discloses a synthesis method of N-(4-cyano-3-(trifluoromethyl) phenyl)-2-methyl epoxypropylene-2-amide, which comprises the following processing steps: S1, dissolving 4-amino-2-trifluoromethyl benzonitrile and a catalyst in dichloromethane, adding methyl methacrylate, heating the liquid to 10-65 DEG C, and reacting for 1-10 hours; S2, after the reaction is finished, cooling and filtering the reaction product and drying the reaction product to remove dichloromethane to obtain N-(4-cyano-3-trifluoromethylphenyl)methacrylamide; S3, adding the N-(4-cyano-3-trifluoromethylphenyl)methacrylamide into a solvent, adding a biphasic catalyst and manganese dioxide, and stirring the mixture for 1 to 3 hours; S4, performing a reaction on the mixture liquid for 10-24 hours, cooling a reaction product to 20-25 DEG C, and filtering and drying the reaction product to obtain the N-(4-cyano-3-(trifluoromethyl)phenyl)-2-methyl epoxypropylene-2-amide. The biphasic catalyst is cyclic crown ethers. Raw materials used in the method are easy to obtain and low in price, reagents and solvents used in the method are of conventional industrial specifications, and the method is suitable for industrial production, extremely small in environmental pollution, low in equipment requirement and high in operation safety.

Owner:SUZHOU UUGENE BIOPHARMA

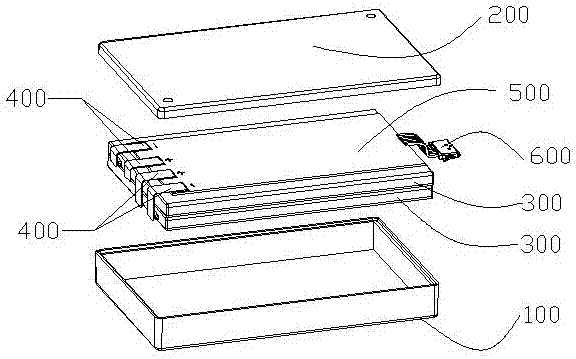

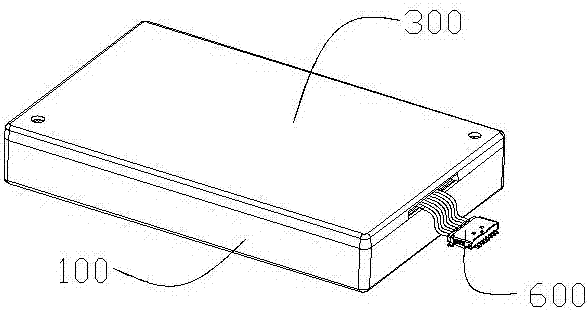

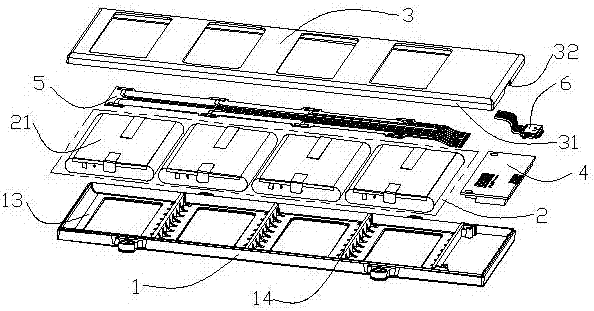

High-voltage explosion-proof battery pack and manufacturing method of battery pack

ActiveCN107146862AAchieve standardizationImprove versatilityFinal product manufactureVent arrangementsElectrical batteryFlexible circuits

The invention relates to a high-voltage explosion-proof battery pack. The high-voltage explosion-proof battery pack comprises a battery box, a battery group and a cover body, wherein the battery group comprises at least two batteries; and the batteries are fixed inside the battery box in a mutual isolation manner. The explosion-proof battery pack also comprises a rigid circuit board, a flexible circuit board and an external connector, one end of the flexible circuit board is connected with the rigid circuit board, the other end of the flexible circuit board is connected with the battery group, and series connection of the batteries is realized; the rigid circuit board and the flexible circuit board are accommodated in the explosion-proof battery box respectively; the rigid circuit board is positioned at the position close to one side of the battery box; the external connector is connected with the rigid circuit board; the cover body also comprises a circular side wall, a through hole is formed in the side wall corresponding to the position of the external connector; the external connector passes through the through hole to be stretched outwards from the cover body; and the box body is assembled with the battery box together.

Owner:POWER IDEA TECH (SHENZHEN) CO LTD

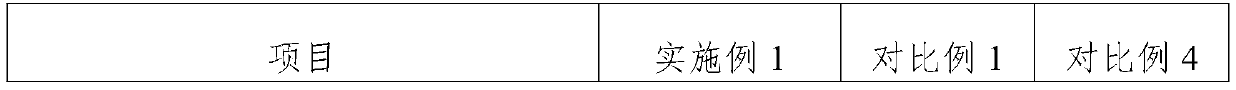

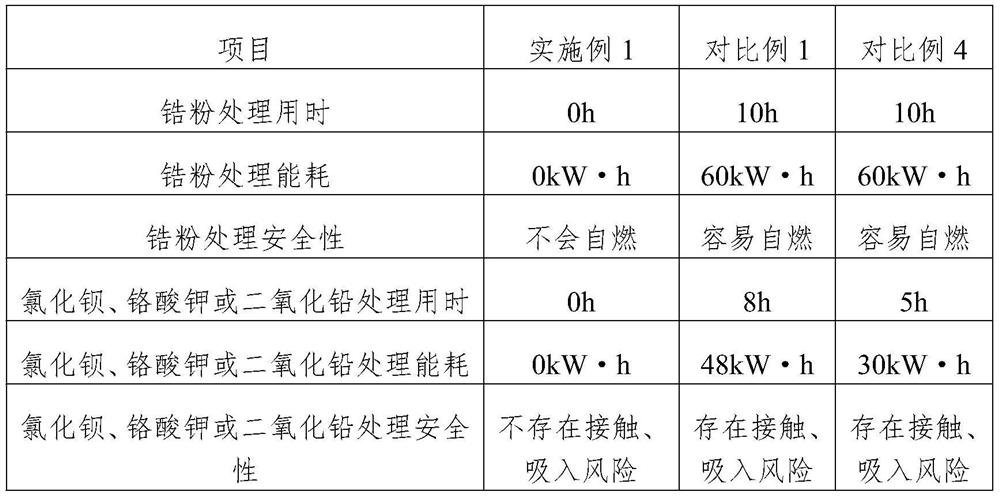

Method for improving safety of ignition paper preparation

ActiveCN109837806AReduce manufacturing costAvoid preprocessingTextiles and paperFiltrationOperation safety

The invention discloses a method for improving safety of ignition paper preparation. The method comprises the following steps: determining the water contents of zirconium powder, barium chloride and potassium chromate, calculating the drying weights of the zirconium powder, the barium chloride and the potassium chromate, and respectively dissolving the barium chloride and the potassium chromate into distilled water so as to obtain a barium chloride solution and a potassium chromate solution; crushing loose asbestos paper into asbestos paper pulp, adding the zirconium powder, uniformly stirringto obtain a mixed solution, sequentially and slowly adding the potassium chromate solution and the barium chloride solution, transferring the mixture into a suction filtration device, standing, and drying to obtain ignition paper. According to the invention, the use safety of the zirconium powder can be effectively ensured, the barium chloride and the potassium chromate are directly used, the pre-treatment of dangerous raw materials is avoided, the contact time of operators and toxic and harmful chemical products is shortened, the production operation safety is improved, the working efficiency of an operator is improved, the energy consumption can be reduced, the preparation working time of each batch of ignition paper is reduced by 24 hours from 68 hours, the electric energy consumptionis reduced from 544 kW * h to 192 kW * h.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

Efficient method for extracting and refining tree moss absolute oil and application thereof

ActiveCN109181877AHigh yieldImprove qualityTobacco treatmentEssential-oils/perfumesHeat not burnElectronic cigarette

The invention discloses an efficient method for preparing tree moss absolute oil. The following devices are used: an ultrasonic extraction tank (1); a chromatography column (2); an air compressor (3);a concentration tank (4); a reverse resin column (5); a condenser (6); a vacuum pump (8); and a solvent recovery tank (7). The method comprises the following steps: 1) performing ultrasonic extraction of a tree moss raw material; 2) performing purification by the chromatography column (2); 3) performing concentration; 4) performing purification by the reverse resin column (5); and 5) removing ethanol under reduced pressure to obtain the tree moss absolute oil. The device of the invention can efficiently extract and purify the tree moss absolute oil, and the obtained tree moss absolute oil isused in the cigarettes, the electronic cigarettes or the heat-not-burn cigarettes, and can effectively improve the smoking comfort.

Owner:CHINA TOBACCO YUNNAN IND

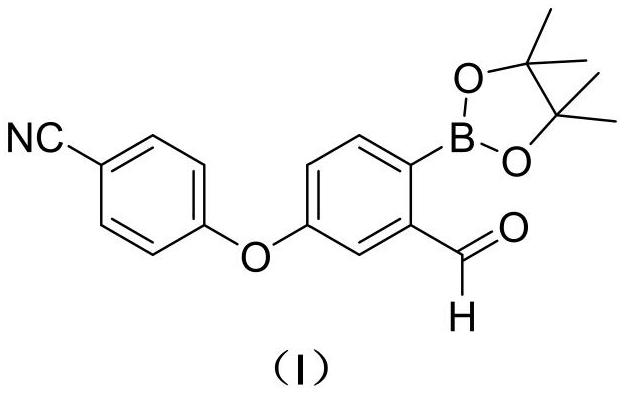

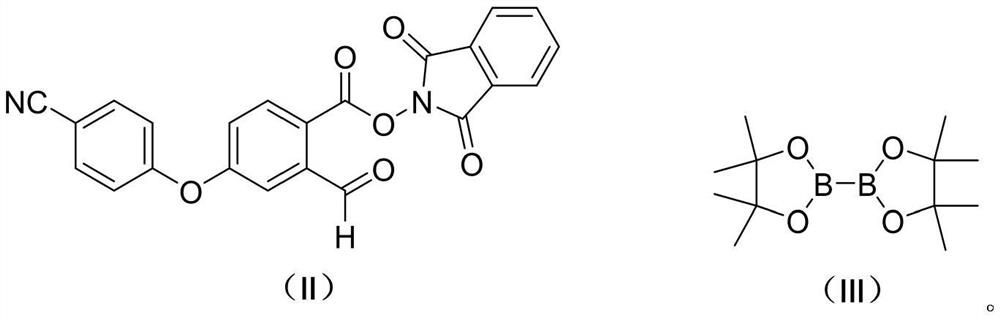

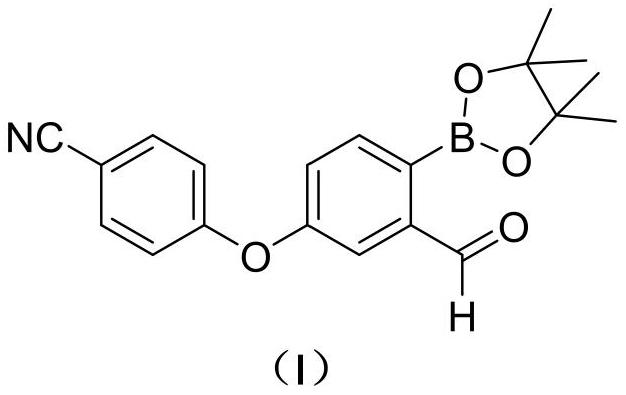

Preparation method of 2-formyl-4-(4-cyanophenoxy) phenylboronic acid pinacol ester

ActiveCN113336780AHigh yieldHigh purityGroup 3/13 element organic compoundsPtru catalystBoronic acid

The present invention relates to a novel process for the preparation of 4-[3-formyl-4-(4, 4, 5, 5-tetramethyl-1, 3, 2-dioxaborol-2-yl) phenoxy] benzonitrile; and the compound is used as an intermediate for the synthesis of crisaborole. The method adopted by the invention is a non-palladium-catalyzed decarboxylation boronation method which takes carboxylic ester as a substrate and isonicotinate as a catalyst; and compared with a palladium-catalyzed coupling boronation method which takes halide as a substrate in the prior art, the method has the advantages of safety in operation, low cost, environmental friendliness and the like.

Owner:SHANDONG ACADEMY OF PHARMACEUTICAL SCIENCES +1

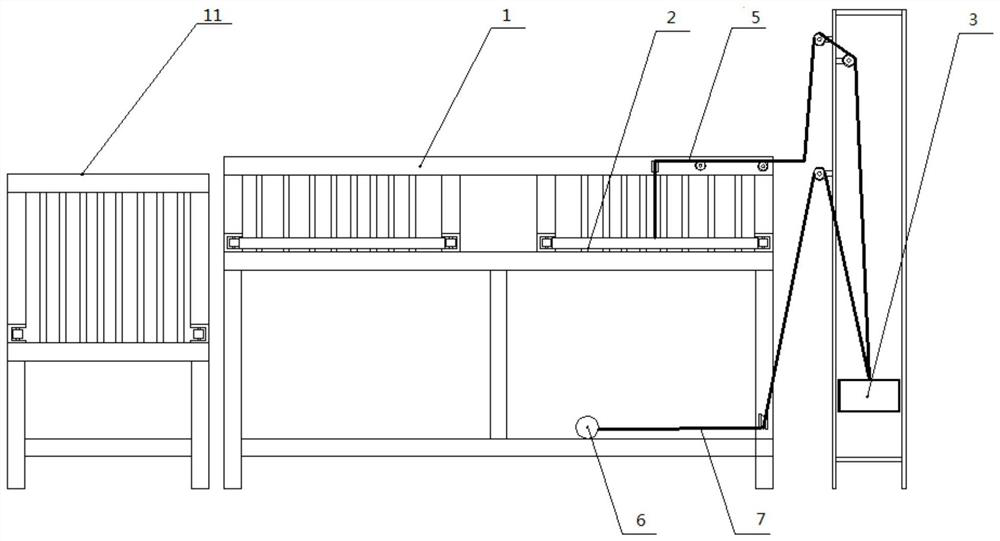

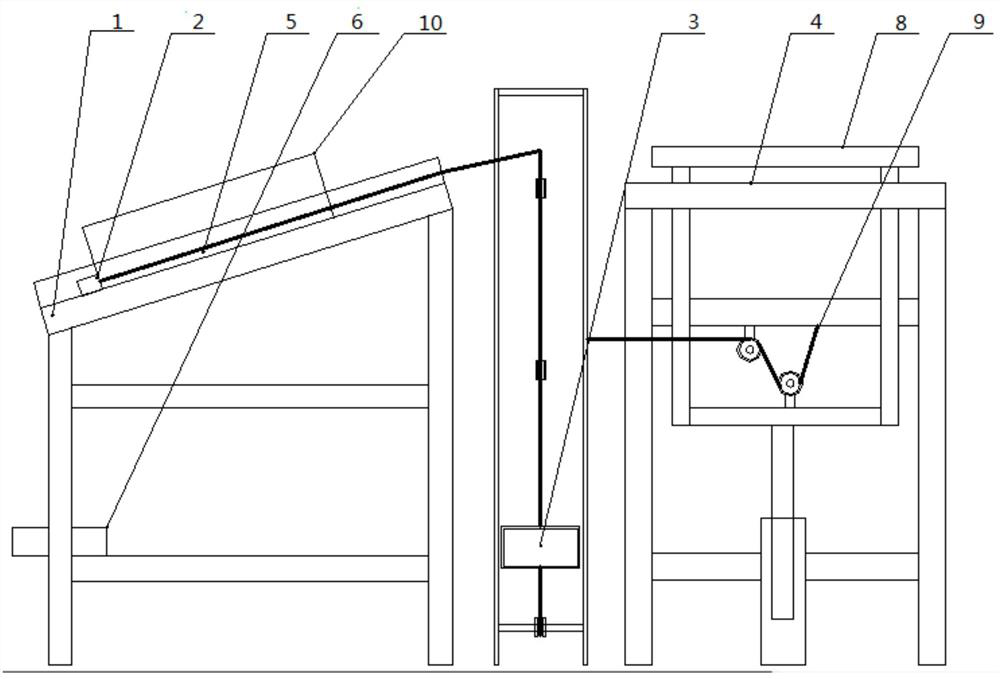

Unpowered loading rack

ActiveCN111348364BImprove feeding efficiencyEliminates lifting actionStorage devicesControl engineeringBlock and tackle

The invention discloses a non-powered loading shelf, which comprises a first station frame with a sloped top, a push rod, a counterweight, a second station frame, and a movable rod arranged on the first station frame; The weight and the movable rod can change the power distance and the power steering principle by using the pulley block. The push rod, the counterweight and the movable rod are linked together. The movement of the movable rod drives the counterweight, and the movement of the counterweight drives the push rod. , the movement of the push rod is used to load the container, which can automatically transport the container with parts to the required place on the shelf, without manual lifting and loading, and solve the problem of handling when the operator is loading the container The problem of difficult operation of heavy objects eliminates the movement of manual loading containers, reduces operating hours, reduces the labor intensity of operators, improves operating efficiency, reduces production costs, and improves the safety of production operations.

Owner:一汽丰田汽车(成都)有限公司

The synthetic method of n-(4 cyano-3-(trifluoromethyl)phenyl)-2-methylepoxypropene-2-amide

ActiveCN111087367BMild reaction conditionsImprove the safety of production operationsOrganic chemistryPtru catalystMethacrylate methyl

The invention discloses a synthesis method of N-(4 cyano-3-(trifluoromethyl)phenyl)-2-methylepoxypropylene-2-amide, which comprises the following processing steps: S1, combining 4- Dissolve amino-2-trifluoromethylbenzonitrile and catalyst in dichloromethane, add methyl methacrylate, raise the temperature to 10~65°C, and react for 1~10h; S2, after the reaction, cool down and filter to dichloro Methane is dried to obtain N-(4-cyano-3-trifluoromethylphenyl) methacrylamide; S3, N-(4-cyano-3-trifluoromethylphenyl) methacrylamide Add to the solvent, add biphasic catalyst and manganese dioxide, stir for 1~3h; S4, pass through the reaction in the mixed solution for 10~24h, cool down to 20~25°C, filter and dry to obtain N‑(4cyano‑ 3‑(trifluoromethyl)phenyl)‑2‑methylepoxypropylene‑2‑amide; the biphasic catalyst is a cyclic crown ether. The raw materials used in the invention are readily available and cheap, and the reagents and solvents used are conventional industrial specifications, suitable for industrial production, with minimal environmental pollution, low equipment requirements and high operational safety.

Owner:SUZHOU UUGENE BIOPHARMA

Cracking catalytic circulation method of three reaction cabins

ActiveCN114405416AImprove mass transfer efficiencyImprove conversion rateCarbon compoundsChemical/physical processesCarbon nanotubeProcess engineering

The invention discloses a cracking catalytic circulation method of three reaction cabins, which comprises the following steps: S2, heating a first reaction cabin, introducing a mixed gas composed of nitrogen and hydrogen into the first reaction cabin through a main feeding gas pipe and a three-way selection valve for reaction, opening a fourth on-off valve and a second on-off valve, and closing other on-off valves; s3, biogas is introduced into a first reaction cabin for reaction through a main feeding gas pipe, and a fourth on-off valve and a second on-off valve are kept in a clamping opening state; s4, biogas enters a second reaction cabin for reaction through a main feeding gas pipe and a three-phase selection valve, and a fifth on-off valve and a third on-off valve are opened; and taking out the carbon nanotubes in the first reaction cabin for recycling. The mass transfer efficiency of the reaction equipment is improved, and efficient utilization of raw material gas and product gas is realized. The continuous production of reaction equipment is realized, the blank time is eliminated, and the utilization rate of the equipment is greatly improved. And the fluid direction opposite to the gravity direction is adopted, so that the production operation safety is improved.

Owner:无锡碳谷科技有限公司

A single-point unbalanced protective casting device for ultra-thin large-scale aluminum-containing steel profile billet and its use method

The invention discloses a single-point unbalanced protection casting device for an ultra-thin large-size aluminum-containing steel profiled blank and a using method thereof, and belongs to the technical field of near-net shape continuous casting in the iron and steel metallurgy industry. The single-point unbalanced protection casting device comprises a tundish, a stopper rod, an upper nozzle, a seat brick, a lower nozzle, a submerged nozzle and an H-shaped blank crystallizer; the stopper rod is arranged at an outlet of the tundish; the outlet of the tundish is provided with the upper nozzle and is fixed by the seat brick; the lower end of the upper nozzle is connected with the lower nozzle; the lower end of the lower nozzle is connected with the submerged nozzle; and the submerged nozzle is positioned at the center of a triangular area of a lateral flange of the H-shaped blank crystallizer. The single-point unbalanced protection casting device further comprises a hollow blowing sleevearranged between the upper nozzle and the lower nozzle; the upper nozzle, the sleeve and the lower nozzle form a steel flow channel; the sleeve is provided with air inlets; the number of the air inlets is more than one; and the air inlets communicate with steel flow channel. The quality of a special-shaped blank product can be improved, the yield of casting blanks is increased, the competitivenessof the product in the market is improved, and the single-point unbalanced protection casting device has the advantages of reasonable design and easiness in application.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

A method for improving the safety of ignition paper preparation

ActiveCN109837806BReduce manufacturing costAvoid preprocessingTextiles and paperBarium dichlorideFiltration

The invention discloses a method for improving safety of ignition paper preparation. The method comprises the following steps: determining the water contents of zirconium powder, barium chloride and potassium chromate, calculating the drying weights of the zirconium powder, the barium chloride and the potassium chromate, and respectively dissolving the barium chloride and the potassium chromate into distilled water so as to obtain a barium chloride solution and a potassium chromate solution; crushing loose asbestos paper into asbestos paper pulp, adding the zirconium powder, uniformly stirringto obtain a mixed solution, sequentially and slowly adding the potassium chromate solution and the barium chloride solution, transferring the mixture into a suction filtration device, standing, and drying to obtain ignition paper. According to the invention, the use safety of the zirconium powder can be effectively ensured, the barium chloride and the potassium chromate are directly used, the pre-treatment of dangerous raw materials is avoided, the contact time of operators and toxic and harmful chemical products is shortened, the production operation safety is improved, the working efficiency of an operator is improved, the energy consumption can be reduced, the preparation working time of each batch of ignition paper is reduced by 24 hours from 68 hours, the electric energy consumptionis reduced from 544 kW * h to 192 kW * h.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

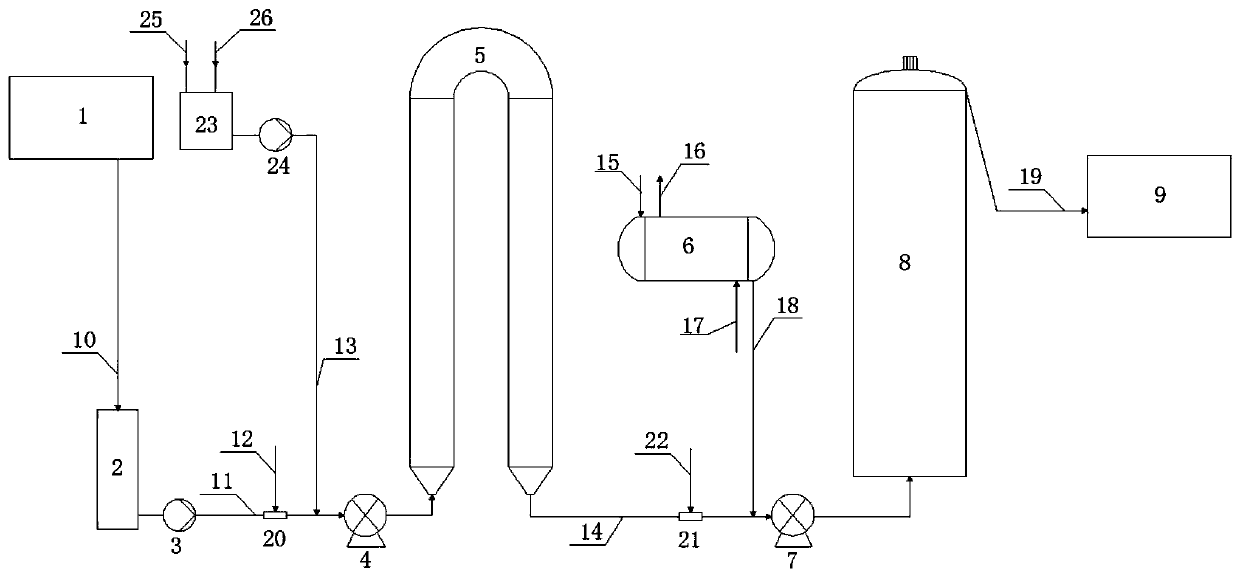

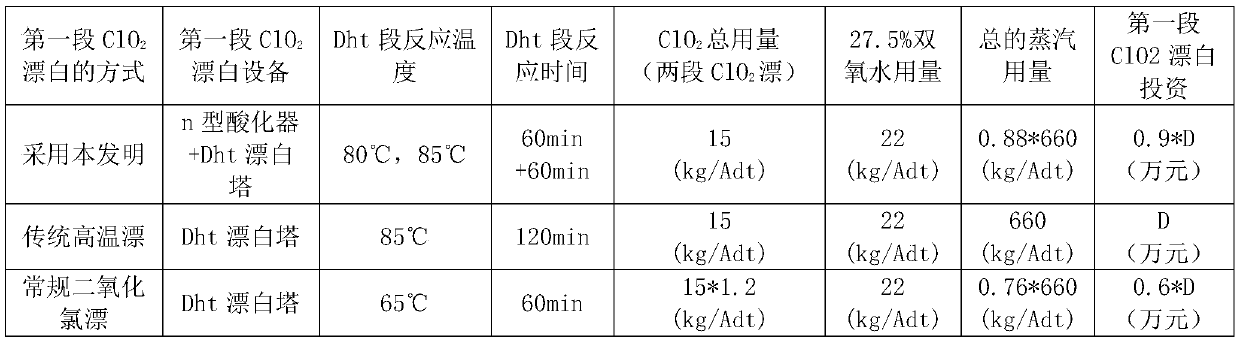

Safe, energy-saving and efficient high-temperature chlorine dioxide paper pulp bleaching method and bleaching device

PendingCN110258160AReduce available chlorine contentReduce consumptionPulp bleachingPipeline systemsChlorine dioxideChloric acid

The invention discloses a safe, energy-saving and efficient high-temperature chlorine dioxide paper pulp bleaching method and a bleaching device. The bleaching device is composed of a pre-bleaching pulp washing machine, a medium concentration standpipe, an acidification steam heater, an acidification mixer, a n-type acidifier, a bleaching steam heater, a bleaching mixer, a high-temperature bleaching tower, a high-temperature leaching stage washer and the like. The bleaching method includes the following steps: firstly, acidifying paper pump in advance by using a high-temperature acidification pretreatment process to acidify and degrade HexA in the paper pulp and neutralize residual alkalis carried by the pulp before bleaching so as to prevent the residual alkalis from reacting with chloric acid produced by hydrolysis of chlorine dioxide; and secondly, mixing the pulp after the high-temperature acidification pretreatment with the chlorine dioxide, and then carrying out high-temperature chlorine dioxide bleaching. The safe, energy-saving and efficient high-temperature chlorine dioxide paper pulp bleaching method and the bleaching device can shorten the reaction time of conventional high-temperature chlorine dioxide bleaching, save the manufacturing cost of the high-temperature bleaching tower and reduce the steam consumption of the bleaching. Moreover, after concentrated sulfuric acid and an acidic mirabilite solution for acidification are mixed and diluted, pulp pipes are added, and so the corrosion is not strong and the production operation safe coefficient is high.

Owner:GUANGXI UNIV

High-efficiency preparation method and application of tobacco absolute

ActiveCN109280581BModerate polarityLow boiling pointTobacco treatmentEssential-oils/perfumesBurn cigaretteElectronic cigarette

Owner:CHINA TOBACCO YUNNAN IND

Efficient preparing method and application of fenugreek absolute oil

ActiveCN109007959AReduce manufacturing costImprove yield and qualityTobacco preparationTobacco treatmentSolventChromatographic column

The invention discloses a preparing method of fenugreek absolute oil. Following devices including an ultrasonic extraction tank (1), a chromatographic column (2), an air compressor (3), a concentration tank (4), a reverse resin column (5), a condenser (6), a vacuum pump (8) and a solvent recovery tank (7) are used. The method includes the steps of firstly, conducting ultrasonic extracting on fenugreek raw materials; secondly, conducting purifying through the chromatographic column (2); thirdly, conducting concentrating; fourthly, conducting purifying through the reverse resin column (5); fifthly, conducting decompressing to remove ethyl alcohol to obtain the fenugreek absolute oil. By means of the devices, the fenugreek absolute oil can be efficiently extracted and purified, the obtained fenugreek absolute oil is used for cigarettes, electronic cigarettes or heated-non-combusted cigarettes, and the sucking comfort is effectively improved.

Owner:CHINA TOBACCO YUNNAN IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com