Preparation method of silicotungstic heteropoly acid

A technology of phosphotungstic heteropoly acid and phosphotungstic acid, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as poor production safety, and achieve improved production and operation safety. The effect of technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Dissolve sodium tungstate with a concentration of 0.01 g / ml and disodium hydrogen phosphate in a concentration range of 0.05 g / ml in 200 ml of hot water. While heating and stirring, add concentrated hydrochloric acid to the solution. After the solution is clear, add 20 Mol / liter C 16 H 33 N + Cl - In the chloroform solution, C 16 H 33 N + Cl - The added amount is 0.05 mol / g sodium tungstate, while vigorously stirring, the phosphotungstic heteropoly acid catalyst is obtained. The catalyst was separated by centrifugation, washed with deionized water until the pH of the washing solution was 5, and then dried under nitrogen flow for 3 hours at a drying temperature of 180°C; and then roasted under nitrogen flow at a temperature of 500°C and a roasting time of 3 hours to produce phosphorus Tungsten heteropoly acid 8.5 g H 3 PW 12 O 40 ·X H 2 O(x=0-30) catalyst.

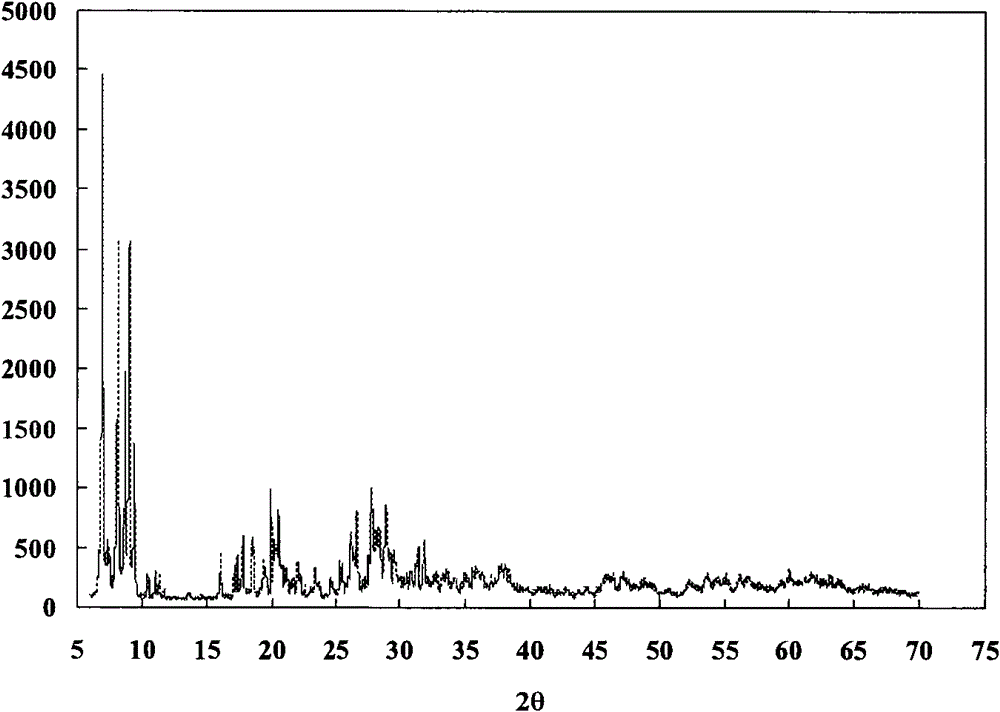

[0018] The XRD spectrum of the sample phosphotungstic acid is shown in figure 1 . From figure 1 It can be seen tha...

Embodiment 2

[0020] Dissolve sodium tungstate with a concentration of 0.05 g / ml and disodium hydrogen phosphate in a concentration range of 0.1 g / ml in 200 ml of hot water. While heating and stirring, add concentrated hydrochloric acid to the solution. After the solution is clear, add concentration 20 mol / L C 18 H 37 N + Cl - In the methylene chloride solution, C 18 H 37 N + Cl - The added amount is 0.1 mol / g sodium tungstate, while vigorously stirring, to obtain phosphotungstic heteropoly acid catalyst. The catalyst was separated by centrifugation, washed with deionized water until the pH of the washing solution was 5, and then dried under nitrogen flow for 10 hours at a drying temperature of 120°C; and then roasted under nitrogen flow at a roasting temperature of 300°C and a roasting time of 8 hours to produce phosphorus Tungsten heteropoly acid 44 g H 3 PW 12 O 40 ·X H 2 O(x=0-30) catalyst.

[0021] The XRD spectrum of the sample phosphotungstic acid and figure 1 Similarly, there are char...

Embodiment 3

[0023] Dissolve sodium tungstate with a concentration of 0.1 g / ml and disodium hydrogen phosphate in a concentration range of 0.15 g / ml in 200 ml of hot water. While heating and stirring, add concentrated hydrochloric acid to the solution. After the solution is clear, add concentration 20 moles / liter C 22 H 45 N + Cl - In ethanol solution, C 22 H 45 N + Cl - The added amount is 0.2 mol / g sodium tungstate, while vigorously stirring, to obtain phosphotungstic heteropoly acid catalyst. The catalyst was separated by centrifugation and washed with deionized water until the pH of the washing solution was 5, and then dried under nitrogen flow for 15 hours at a drying temperature of 80°C; and then roasted under nitrogen flow at a roasting temperature of 350°C and a roasting time of 6 hours to produce phosphorus Tungsten heteropoly acid 88 g H 3 PW 12 O 40 ·X H 2 O(x=0-30) catalyst.

[0024] The XRD spectrum of the sample phosphotungstic acid and figure 1 Similarly, there are characteris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com