Safe, energy-saving and efficient high-temperature chlorine dioxide paper pulp bleaching method and bleaching device

A chlorine dioxide and pulp bleaching technology, applied in pulp bleaching, pipeline systems, mechanical equipment, etc., can solve the problem that chlorine dioxide bleaching cannot be widely promoted, the comprehensive production cost has no significant advantages, and the chlorine dioxide bleaching tower has a large volume. The problem is to avoid exothermic corrosion of the pulp tube, improve the safety of production operations, and save production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

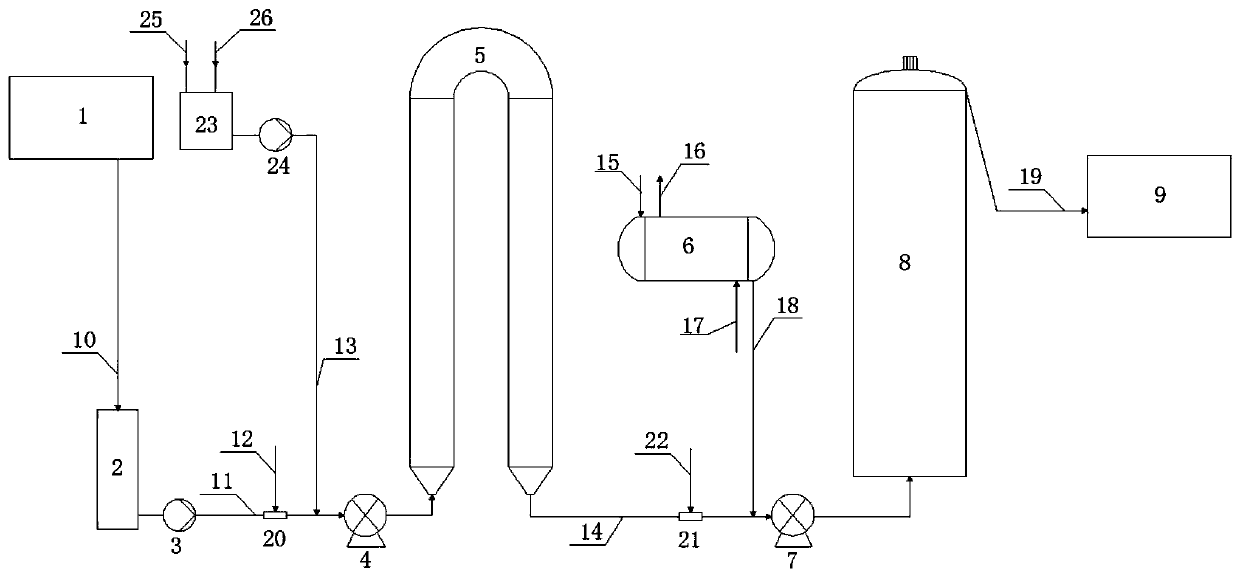

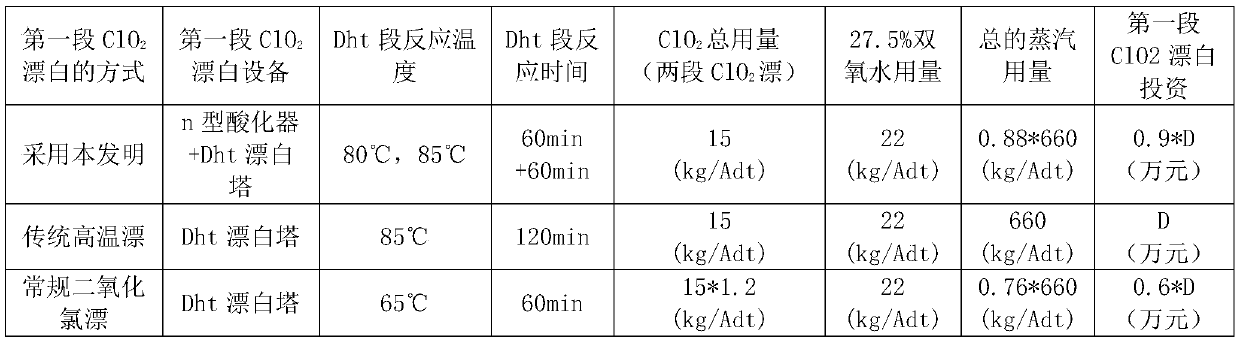

[0033] Embodiment 1, adopt Dht-Ep-D1 process, bleach the bagasse pulp that does not carry out oxygen de-treatment, concrete operating steps are as follows:

[0034]Step 1, pulp high-temperature acidification pretreatment: the pre-bleaching pulp is washed and concentrated to a concentration of 10% by the pre-bleaching pulp washer 1, then enters the medium-consistency riser 2, and is sent to the acidification steam heater 20 by the medium-consistency pump 3 for heating, and then Enter the acidification mixer 4 and mix with dilute sulfuric acid of 10% mass concentration from the dilute acid tank 23, and control the pH value after the high-temperature bleaching reaction to be 2.2, and then enter the n-type acidifier 5 for acid-base neutralization and acidification Degrades HexA. The acidification reaction temperature was 80°C, and the pre-acidification treatment time was 60 minutes.

[0035] Step 2, chlorine dioxide preheating: before chlorine dioxide is mixed with pulp, the blea...

Embodiment 2

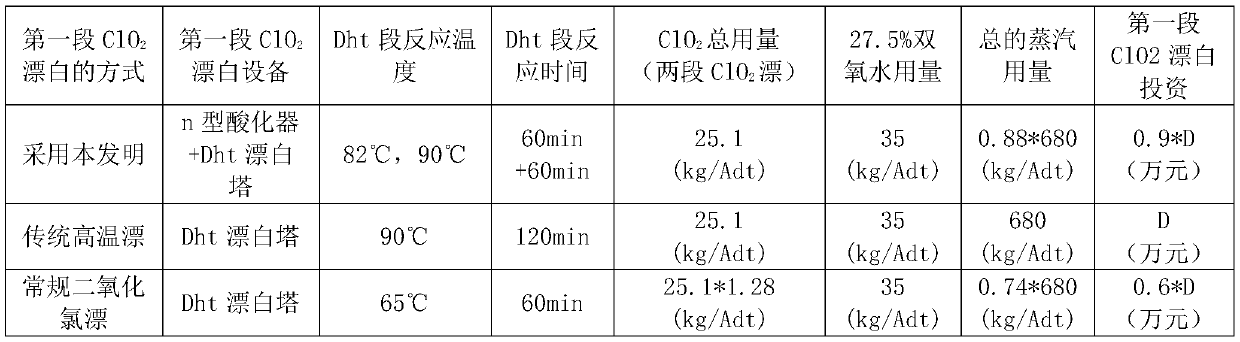

[0042] Embodiment 2, adopt Dht-Ep-D1 process, bleach the mixed pulp of eucalyptus and bagasse (eucalyptus accounts for 25%) that does not carry out deoxygenation treatment, concrete steps are as follows:

[0043] Step 1, pulp high-temperature acidification pretreatment: the pre-bleaching pulp is washed and concentrated to a concentration of 10.8% by the pre-bleaching pulp washer 1, then enters the medium-consistency riser 2, and is sent to the acidification steam heater 20 by the medium-consistency pump 3 for heating, and then Enter the acidification mixer 4 and mix with dilute sulfuric acid with a mass concentration of 10% from the dilute acid tank 23, and control the pH value after the high-temperature bleaching reaction to 2.5, and then enter the n-type acidifier 5 for acid-base neutralization and acidification To degrade HexA, the acidification reaction temperature was 82°C, and the pre-acidification treatment time was 60min.

[0044] Step 2, chlorine dioxide preheating: b...

Embodiment 3

[0051] Embodiment 3, adopt Dht-Ep-D1 process, bleach the mixed pulp of eucalyptus and bagasse (eucalyptus accounts for 50%) that does not carry out deoxygenation treatment, concrete steps are as follows:

[0052] Step 1, pulp high-temperature acidification pretreatment: the pre-bleaching pulp is washed and concentrated to a concentration of 11.9% by the pre-bleaching pulp washer 1, then enters the medium-consistency riser 2, and is sent to the acidification steam heater 20 by the medium-consistency pump 3 for heating, and then Enter the acidification mixer 4 and mix with dilute sulfuric acid of 10% mass concentration from the dilute acid tank 23, and control the pH value after the high-temperature bleaching reaction to be 2.6, and then enter the n-type acidifier 5 for acid-base neutralization and acidification To degrade HexA, the acidification reaction temperature was 85°C, and the pre-acidification treatment time was 60min.

[0053] Step 2, chlorine dioxide preheating: befor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com