AKD emulsion stabilized by a combination of PAE and sodium alginate synergist and preparation method thereof

A technology of sodium alginate and synergist, which is applied in the direction of water-repellent addition, textile and papermaking, non-fiber pulp addition, etc. It can solve the problem of high cost and achieve the effect of low cost, simple equipment and reduced dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

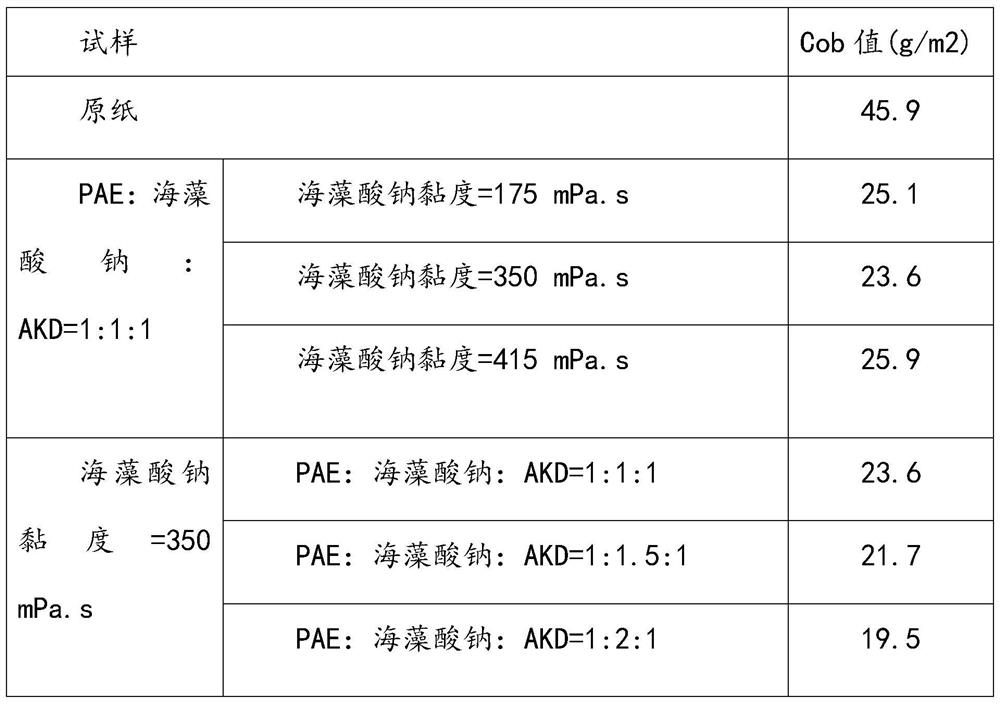

[0020] (1) Take sodium alginate with a viscosity of 175mPa.s and dissolve it in an appropriate amount of water to make the concentration 0.003g / mL, and stir magnetically to make it evenly dispersed.

[0021] (2) Dissolve PAE in an appropriate amount of water at room temperature with a concentration of 1%, and magnetically stir for 10 minutes to disperse evenly.

[0022] (3) Heat 100 parts of AKD wax flakes in a water bath, then pour sodium alginate and PAE combined emulsifier into the oily liquid of AKD wax flakes at one time, stir at 10000r / min high-speed shear for 3 minutes to prepare AKD emulsion, and make PAE : Sodium alginate: AKD=1:1:1.

Embodiment 2

[0024] (1) Dissolve sodium alginate with a viscosity of 350mPa.s in an appropriate amount of water to a concentration of , and magnetically stir to disperse it evenly.

[0025] (2) Dissolve PAE in an appropriate amount of water at room temperature with a concentration of 1%, and magnetically stir for 10 minutes to disperse evenly.

[0026] (3) Heat 100 parts of AKD wax flakes in a water bath, then pour sodium alginate and PAE joint emulsifier into the oily liquid of AKD wax flakes at one time, so that PAE: sodium alginate: AKD = 1:1:1, and then 10000r / min high-speed shear stirring for 3 minutes to prepare the AKD emulsion.

Embodiment 3

[0028] (1) Take sodium alginate with a viscosity of 415mPa.s and dissolve it in an appropriate amount of water to make the concentration 0.003g / mL, and stir magnetically to make it evenly dispersed.

[0029] (2) Dissolve PAE in an appropriate amount of water at room temperature with a concentration of 1%, and magnetically stir for 10 minutes to disperse evenly.

[0030] (3) Heat 100 parts of AKD wax flakes in a water bath, then pour sodium alginate and PAE joint emulsifier into the oily liquid of AKD wax flakes at one time, so that PAE: sodium alginate: AKD = 1:1:1, and then 10000r / min high-speed shear stirring for 3 minutes to prepare the AKD emulsion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com