Unpowered loading rack

A power and shelf technology, applied in the field of unpowered loading shelves, can solve problems such as difficulties in handling heavy objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

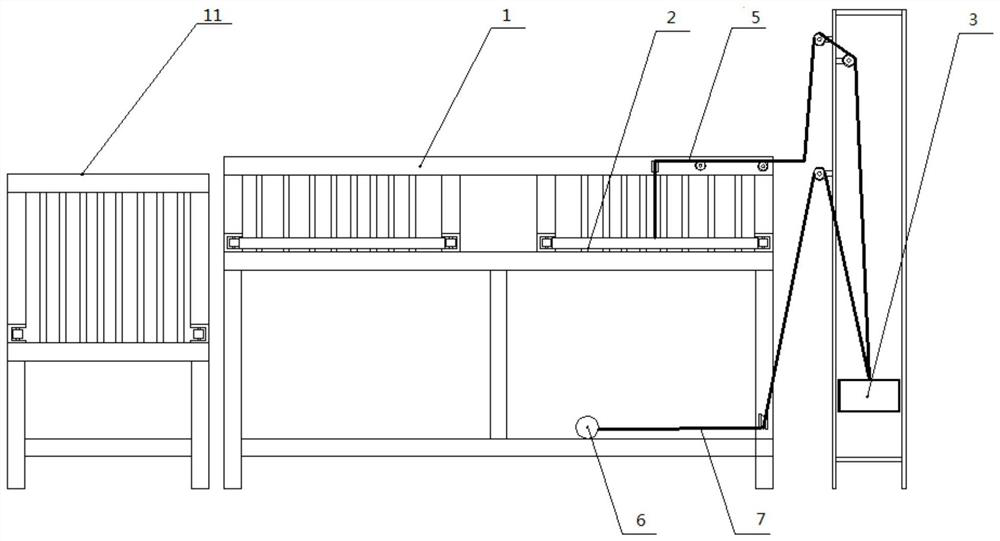

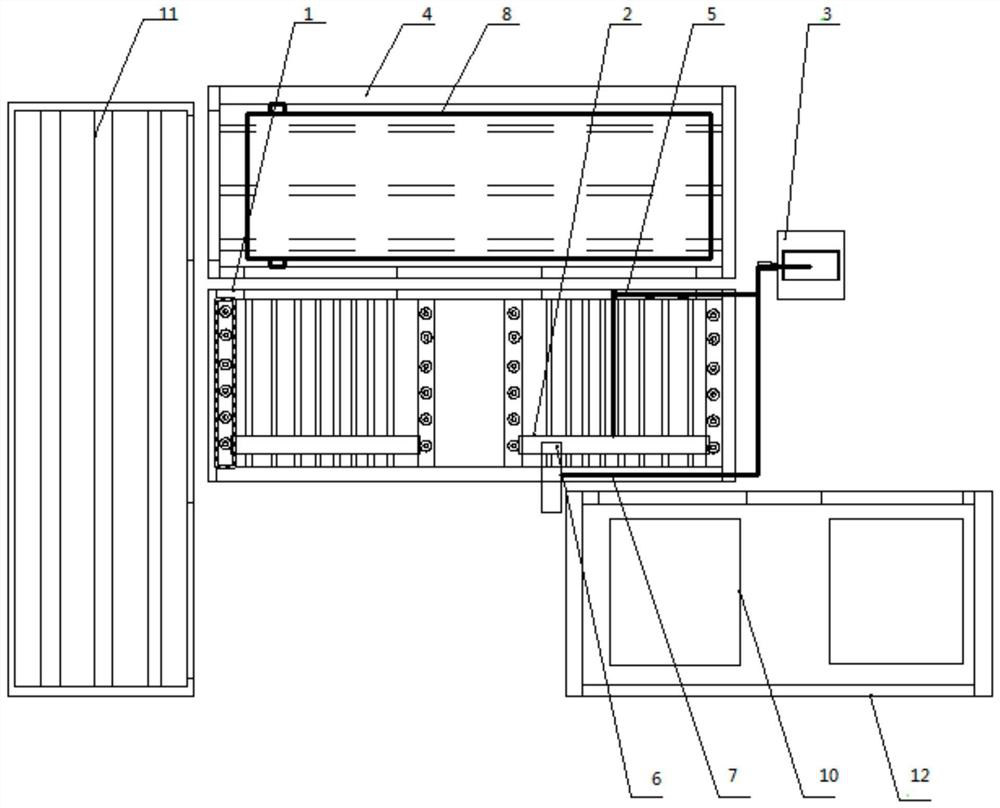

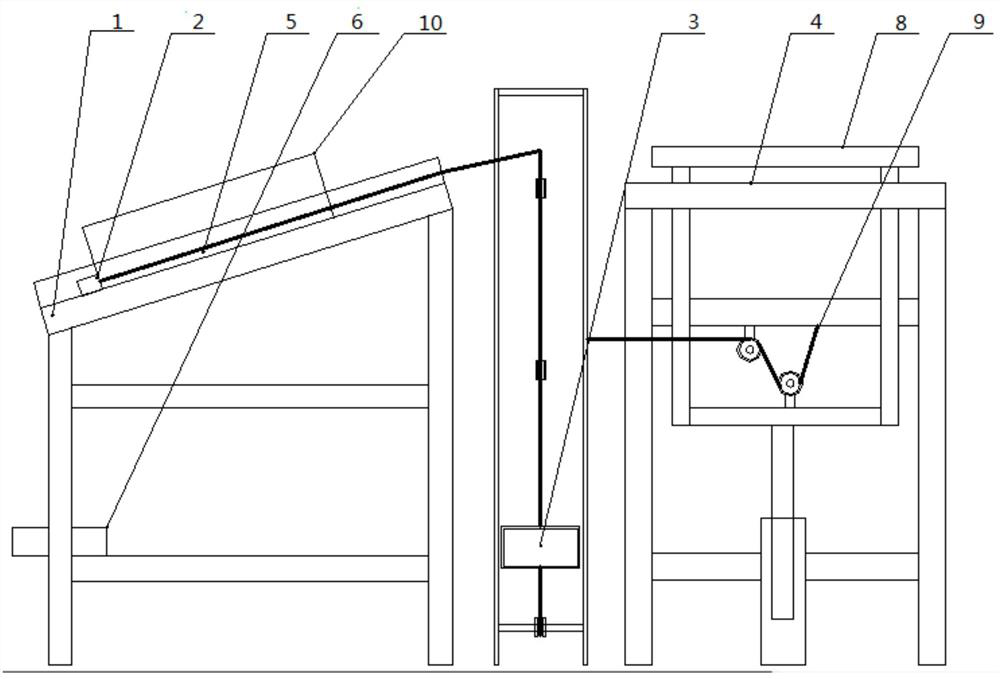

[0022] like Figure 1~3 As shown, the unpowered loading rack provided by this program includes a first station frame 1 with a sloped top, a push rod 2, a counterweight 3, and a second station frame 4; the first station frame 1 is Cargo box 10 loading station, the first station frame 1 is provided with a plurality of pulley blocks for changing the power transmission direction; the push rod 2 is located on the slope of the first station frame 1, and the push rod 2 can be The first station frame 1 loads the cargo box 10 and slides in a straight line; the counterweight 3 is arranged on the side of the first station frame 1, and the counterweight 3 can move linearly in the vertical direction; the push rod 2 is provided with a second A stay rope 5, the first stay rope 5 passes through the pulley block and one end of the first stay rope 5 is connected with the push rod 2, and the other end is connected with the counterweight 3, and the counterweight 3 moves downward and pulls the pus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com