Wheel turning sling of high speed motor train unit

A high-speed EMU and wheel technology, applied in the field of flipping spreaders, can solve problems such as low production efficiency and large safety hazards in the operation process, and achieve the effects of improving production efficiency, improving production safety, and shortening the required time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

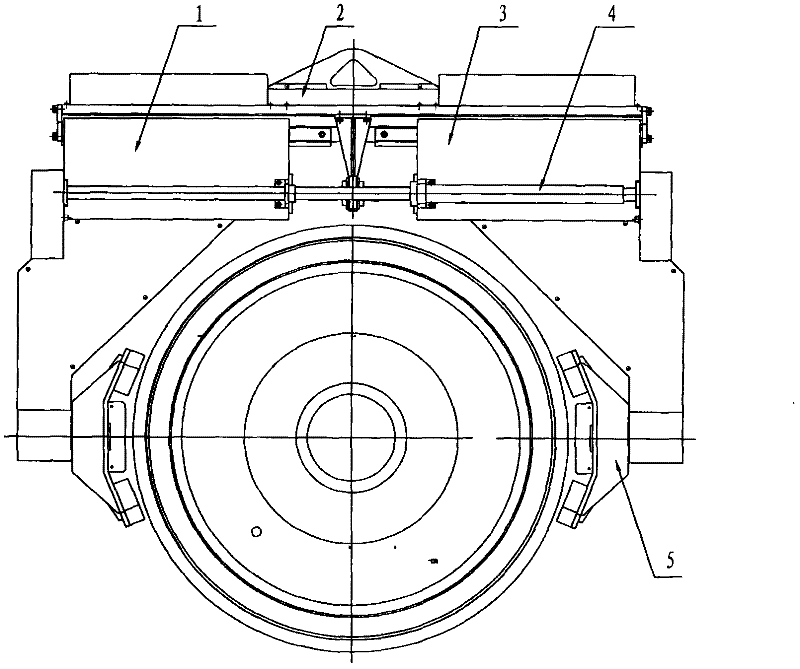

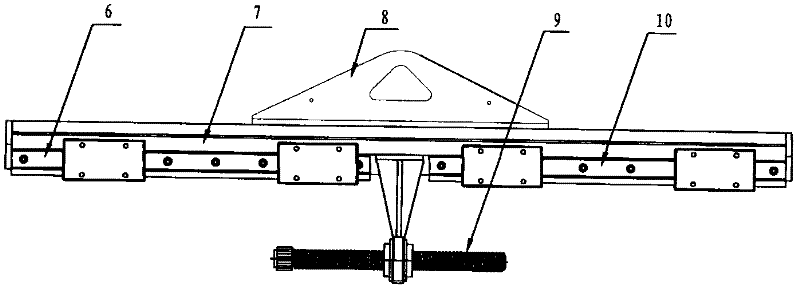

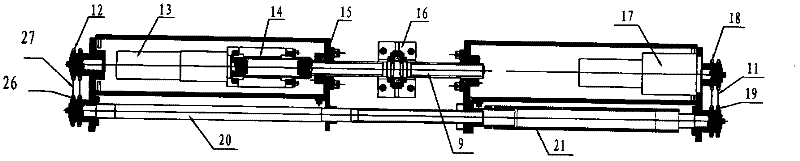

[0012] A high-speed EMU wheel turning spreader, comprising a suspension beam 2, a left suspension arm 1, a right suspension arm 3, a claw 5 and a transmission mechanism 4, a left guide rail 6 is arranged on the left part of the beam 7 of the suspension beam 2, and the The right part of crossbeam 7 is provided with right guide rail 10, and left guide rail 6 and right guide rail 10 are arranged on a straight line, is provided with leading screw 9 in the screw bearing seat 16 of the middle part of crossbeam 7, and the left part screw thread of leading screw 9 It is arranged in the opposite direction with the right threaded button. A left lead screw nut 15 is arranged on the left side of the lead screw 9, a right lead screw nut is arranged on the right part of the lead screw 9, and the left lead screw nut is movable with the left guide rail. The left boom 1 on 6 is fixedly connected, the right lead screw nut is fixedly connected with the right boom 3 which is movably arranged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com