Cracking catalytic circulation method of three reaction cabins

A pyrolysis catalysis and reaction chamber technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of poor product gas delivery, rising pressure in the reaction system, and reduced equipment utilization, and achieve a balanced reaction. Right shift, increase the rate of detachment, improve the effect of diffusion uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

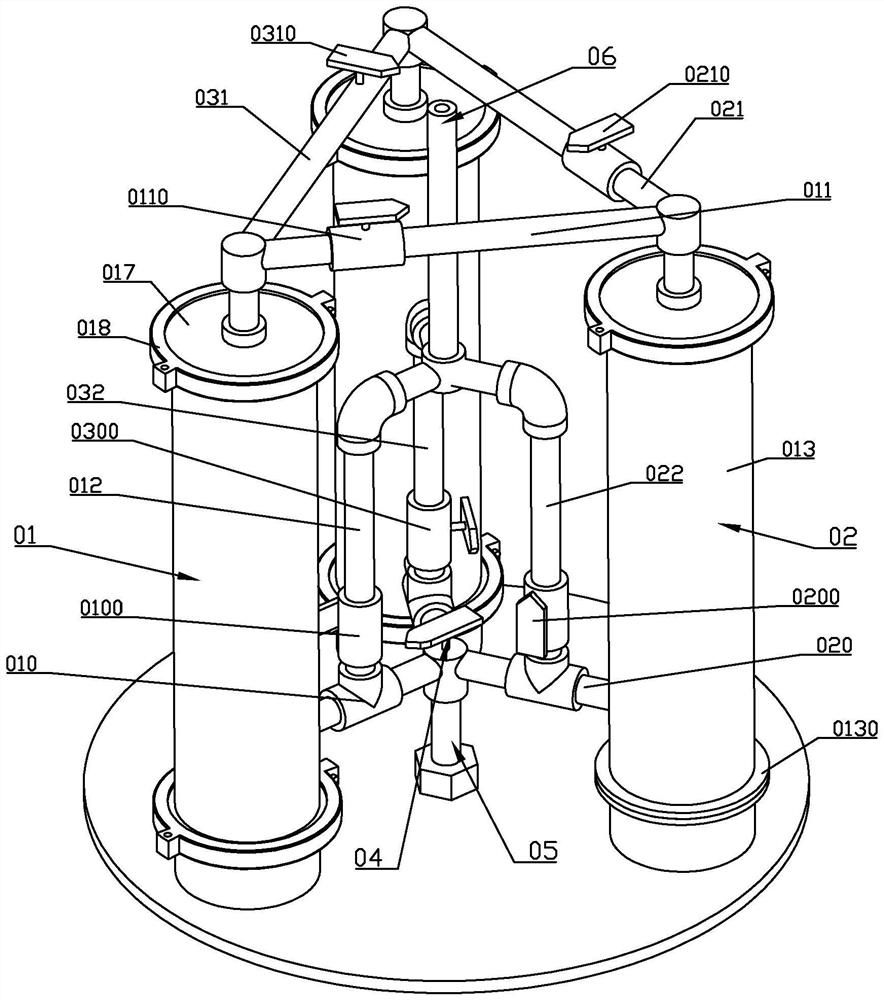

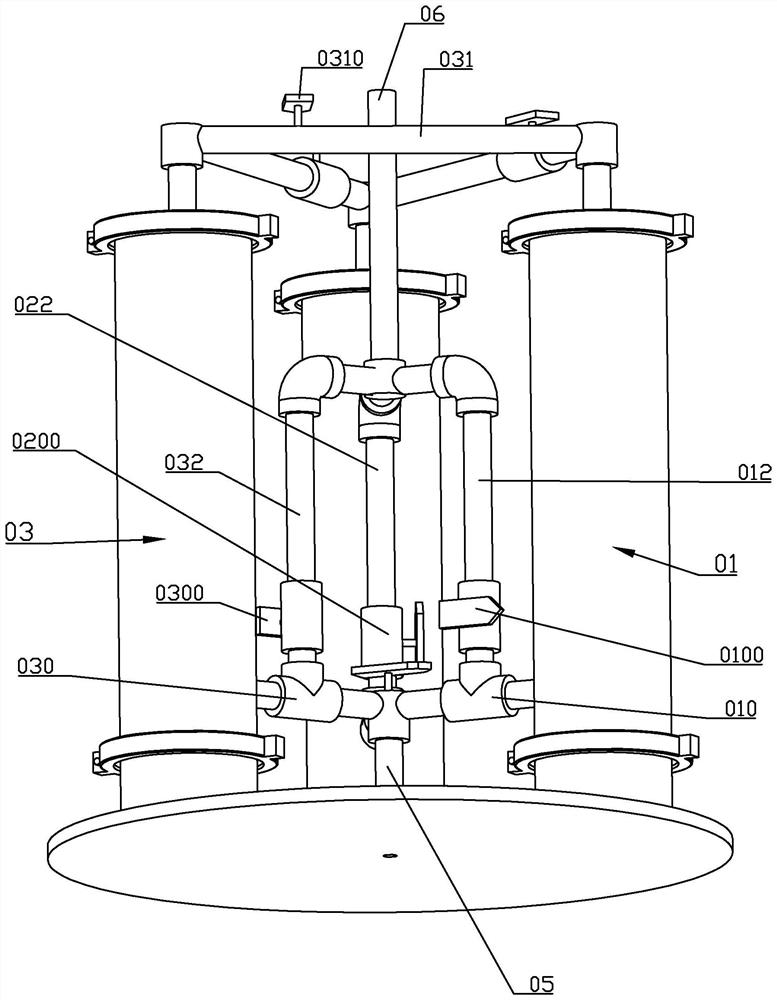

[0034] The present embodiment provides a kind of cracking catalytic cycle method of three reaction chambers, comprising the following steps:

[0035] S1: Prepare the first reaction chamber 01, the second reaction chamber 02, and the third reaction chamber 03; the three reaction chambers have the same structure, which can be easily replaced and used, and the serial numbers are marked between the three reaction chambers for distinction; the three reaction chambers All can independently realize the process of heating, reducing, cracking and catalyzing, and cooling;

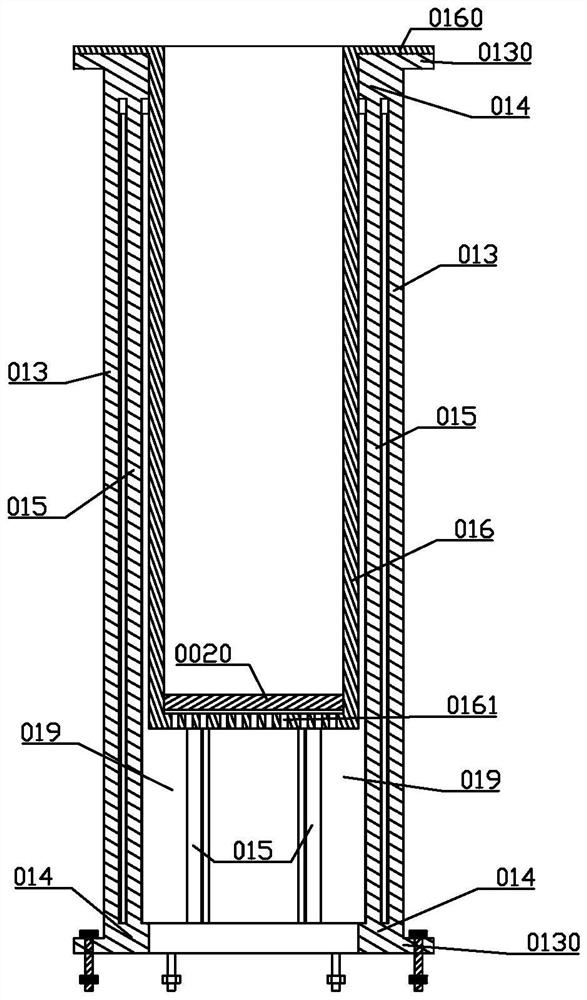

[0036] The bottom side of the first reaction chamber 01 is connected with the first feed gas pipe 010; the first gas inlet pipe is made of plastic pipe or metal pipe for guiding the gas flow; the middle part of the first feed gas pipe 010 is connected with the first stop valve 0100; the first stop valve 0100 is used to control the outflow of gas from the middle of the first feed gas pipe 010, and open or close the fi...

Embodiment 2

[0066] S1 step is identical with embodiment 1;

[0067] S2: Heating the temperature of the first reaction chamber 01, the mixed gas composed of nitrogen and hydrogen, the mixed gas is N2:H2=1:1; through the main feed gas pipe 05 and through the three selection valve 04, introduce the first reaction chamber 01 to react, Open the fourth stop valve 0110, the second stop valve 0200, and close the other stop valves; the total flow rate of reducing gas is 1.0L / min, the furnace temperature is 500±10°C, and the reduction time is 30min; reduction reaction: MOx+xH2 →M+xH2O, MOx refers to the metal oxide in the reduction reaction. All other check valves are closed;

[0068] S3: Through the main feed air pipe 05, biogas is introduced into the first reaction chamber 01 for reaction, and the biogas is CH4:H2=10:1; keep the fourth through-stop valve 0110 and the second through-stop valve 0200 in the card open state ;The total flow rate of biogas is 1.5L / min, the furnace temperature is 600±...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com