Method for producing fully synthetic lubricating oil from grease

A lubricating oil base oil and grease technology, which is applied in the direction of hydrocarbon oil treatment products, preparation of liquid hydrocarbon mixture, and treatment of hydrocarbon oil, can solve the problems of pour point and high temperature oxidation stability gap, low production cost, etc., and improve production Operational safety, low cost, and production cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

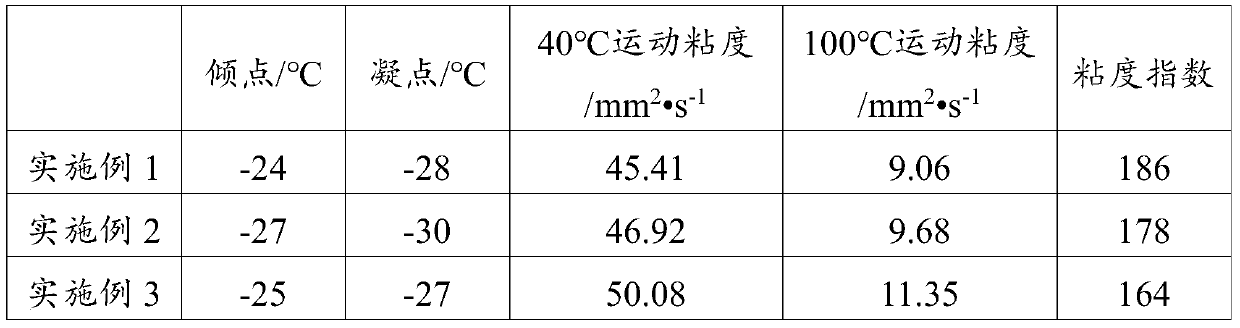

Examples

Embodiment 1

[0021] 1.1 Direct deoxygenation of fatty acids into long chain olefins

[0022] The deoxygenation catalyst is prepared by the impregnation method: the Pt precursor PtCl is mixed with the Pt:Sn ratio of 5:1 4 And Sn precursor SnCl 4 Dissolve. SiO 2 The powder is added to the metal mixed solution, the total amount of metal accounts for SiO 2 5% of the quality. The mixture was stirred to dryness, dried at 80°C overnight, and then ground into powder. The powder was calcined in air at 350°C, and then reduced with hydrogen at the same temperature to obtain a deoxygenation catalyst.

[0023] In this example, octadecanoic acid was used as a raw material. Add 1g of deoxygenation catalyst into the reaction kettle, add 10g of octadecanoic acid, and then add 80ml of dodecane as solvent. After sealing the reactor, first use N 2 Replace the air in the reactor and fill it with 1MPa N 2 . The reaction kettle was heated to 320°C and reacted for 10 hours.

[0024] After the reaction is completed,...

Embodiment 2

[0031] 2.1 Direct deoxygenation of grease to long-chain olefins

[0032] The deoxygenation catalyst is prepared by the impregnation method: Pd is the precursor of PdCl in the ratio of Pd:Sn 1:1 2 And Sn precursor SnCl 4 Dissolve. SiO 2 The powder is added to the metal mixed solution, the total amount of metal accounts for SiO 2 2% of the quality. The mixture was stirred to dryness, dried at 80°C overnight, and then ground into powder. The powder was calcined in air at 350°C, and then reduced with hydrogen at the same temperature to obtain a deoxygenation catalyst.

[0033] In this embodiment, palm oil is used as a raw material. Put 5g of deoxygenation catalyst into the reactor, add 20g of palm oil, and then add 80ml of dodecane as solvent. After sealing the reactor, first use N 2 Replace the air in the reactor and fill it with 1MPa N 2 . The reactor was heated to 350°C and reacted for 24 hours.

[0034] After the reaction is over, after the kettle body is cooled to room temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com