Single-point unbalanced protection casting device for ultra-thin large-size aluminum-containing steel profiled blank and using method thereof

A technology of large-size and special-shaped blanks, which is applied in the field of single-point unbalanced protective casting devices, can solve problems such as asymmetrical and uneven temperature field distribution, growth of casting blank shells in the crystallizer, and uneven melting of mold slag, etc. Low, stable liquid level fluctuations, the effect of force balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

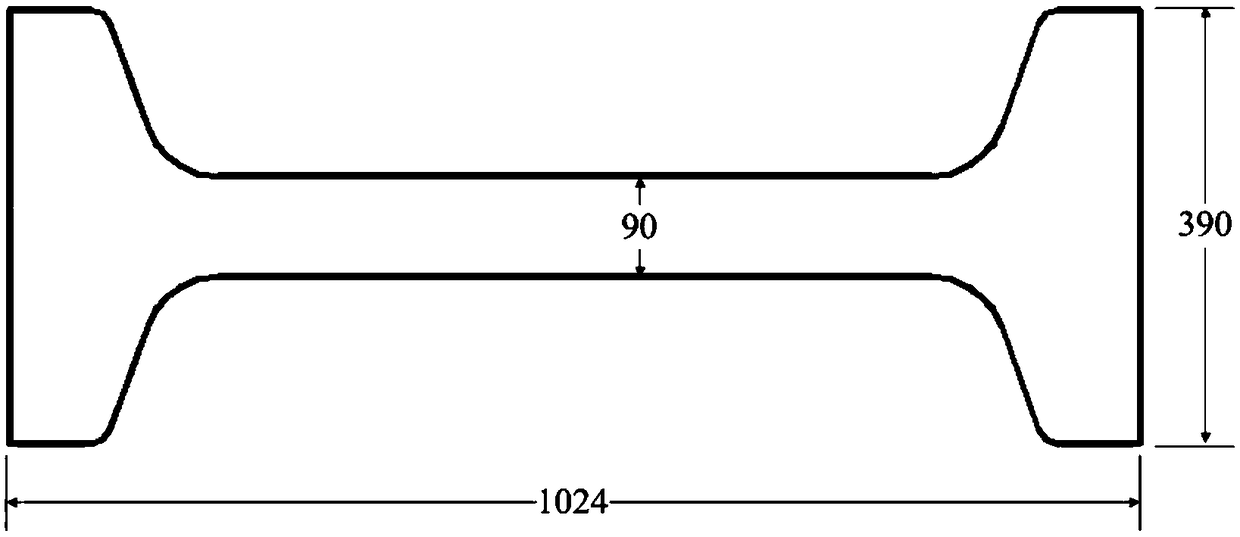

[0083] The continuous casting machine in this embodiment is an H-shaped profiled billet with three machines and three streams. The section size of the casting H-shaped profiled billet is 1024mm×390mm×90mm. The specific structure is as follows figure 1 As shown; the web thickness of the special-shaped billet is 90mm, which is the thinnest special-shaped billet in China at present, and the width of 1024mm belongs to the special-shaped billet with a large section. Aluminum (0.015%-0.060%) oil and gas plant project steel C345 series steel grades, in the case of using double nozzles to open and protect the casting can not be realized, the web is too thin web center single nozzle casting is impossible, the invention is adopted The proposed single-point unbalanced casting device and method in the triangular area on one side of the flange of the profiled billet, the continuous casting machine can safely and stably produce qualified ultra-thin and large-section profiled billets in batch...

Embodiment 2

[0099] This embodiment is the same as the structure, usage method and continuous casting method of the device in Embodiment 1, the difference lies in that the present invention is explained and provided with basis by selecting different numerical values.

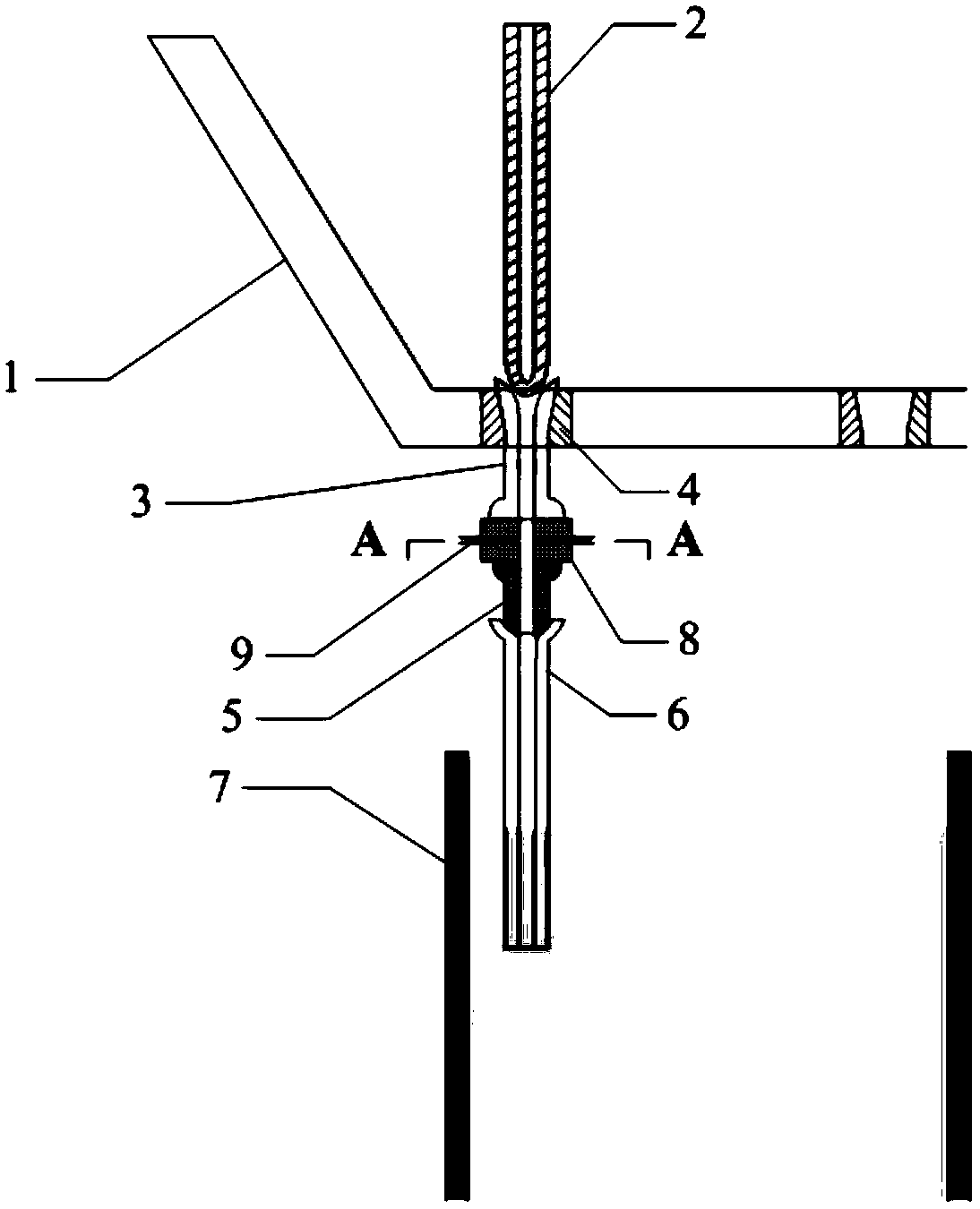

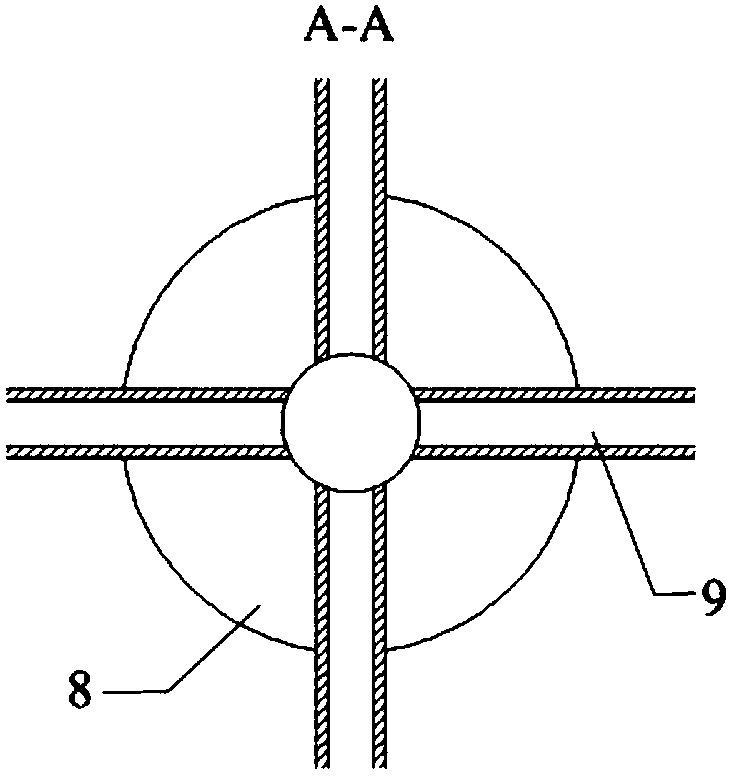

[0100] A single-point unbalanced protective casting device for ultra-thin and large-sized aluminum-containing steel shaped billets, including a tundish 1, a stopper rod 2, an upper nozzle 3, a seat brick 4, a lower nozzle 5, a submerged nozzle 6, and H-shaped billet crystallization 7, the stopper rod 2 is placed in the tundish 1, the lower end of the stopper rod 2 is provided with a seat brick 4, the upper nozzle 3 is connected with the tundish 1, and is fixed by the seat brick 4, the lower end of the upper nozzle 3 is connected with the lower nozzle 5, and the lower end of the upper nozzle 3 is connected with the lower nozzle 5. The lower end of the nozzle 5 is connected with a submerged nozzle 6, and also includes a hollow ...

Embodiment 3

[0114] This embodiment is the same as the structure, usage method and continuous casting method of the device in Embodiment 1, the difference lies in that the present invention is explained and provided with basis by selecting different numerical values.

[0115] A single-point unbalanced protective casting device for ultra-thin and large-sized aluminum-containing steel shaped billets, including a tundish 1, a stopper rod 2, an upper nozzle 3, a seat brick 4, a lower nozzle 5, a submerged nozzle 6, and H-shaped billet crystallization 7, the stopper rod 2 is placed in the tundish 1, the lower end of the stopper rod 2 is provided with a seat brick 4, the upper nozzle 3 is connected with the tundish 1, and is fixed by the seat brick 4, the lower end of the upper nozzle 3 is connected with the lower nozzle 5, and the lower end of the upper nozzle 3 is connected with the lower nozzle 5. The lower end of the nozzle 5 is connected with a submerged nozzle 6, and also includes a hollow ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com