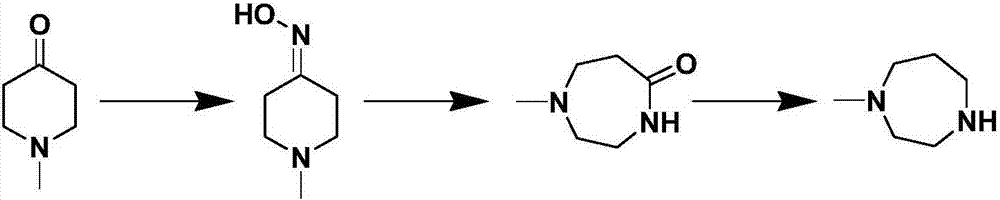

Process for preparing N-methyl homopiperazine from 2-haloethylamine compound

A technology of methylhomopiperazine and haloethylamine, which is applied in the field of preparing N-methylhomopiperazine, can solve the problems of unstable yield, violent heat release, and many wastes, and achieve high production operation safety, The effect of simple synthesis process and convenient reaction operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0077] The method for preparing homopiperazine described in this example may further comprise the steps:

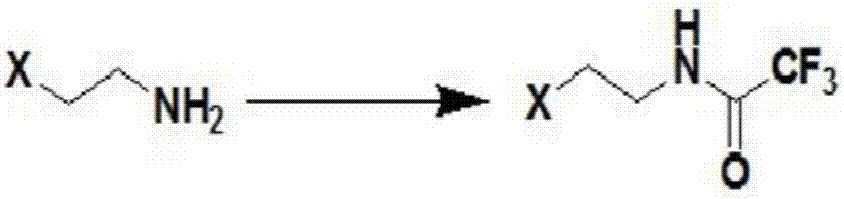

[0078] Step 1: Preparation of N-(2-chloroethyl)trifluoroacetamide

[0079]

[0080] Under stirring at room temperature, add 30L of ethanol, 3.48kg of 2-chloroethylamine hydrochloride and 4.27kg of ethyl trifluoroacetate to the 50L reaction kettle in sequence, stir well, cool to 0°C, and dropwise add 3.04kg of triethylamine , 2 hours to drop. After dripping, react at room temperature for 4 hours, and the reaction ends.

[0081] Ethanol was recovered by distillation under reduced pressure, and the residue was beaten and washed with 10 L of tap water. Filtrate, drain the filter cake, and dry in an oven at 50°C for 4 hours to obtain 4.92Kg of a white low-melting solid product with a yield of 93.4% and a melting point of 59-60°C.

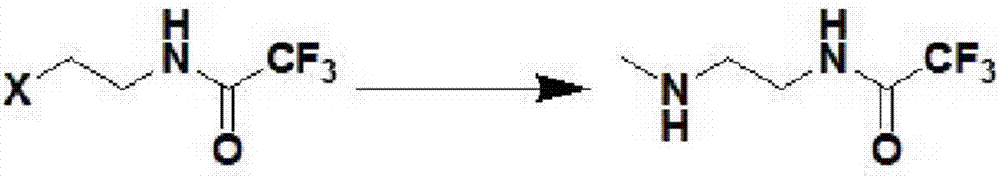

[0082] Step 2: Preparation of N-methyl-N'-trifluoroacetylethylenediamine

[0083]

[0084] Under stirring at room temperature, 25L of ace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com