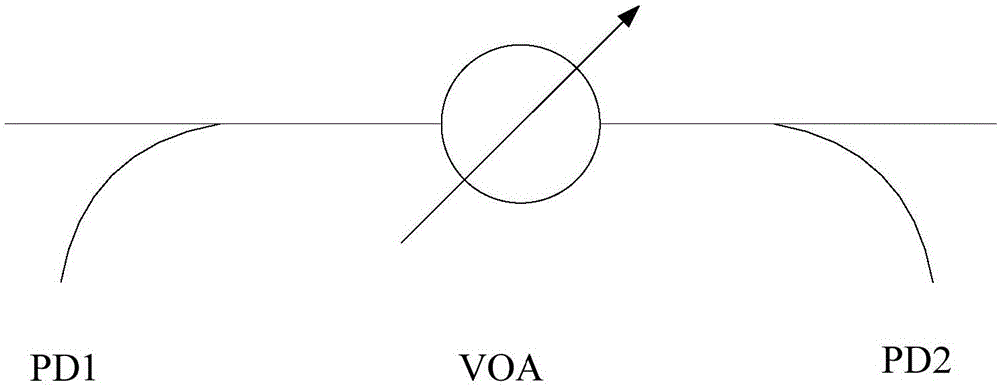

Variable optical attenuator control method and system based on automatic calibration and intelligent learning

A technology of dimming attenuation and automatic calibration, which is applied in the general control system, control/adjustment system, adaptive control, etc. It can solve the problems of unable to correct additional errors, long adjustment time, and time is not fixed, so as to save manual work Time and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to make the objectives, technical solutions, and advantages of the embodiments of the present invention clearer, the technical solutions of the present invention will be introduced below in conjunction with the embodiments of the present invention and the accompanying drawings.

[0056] Design of the present invention mainly comprises three parts:

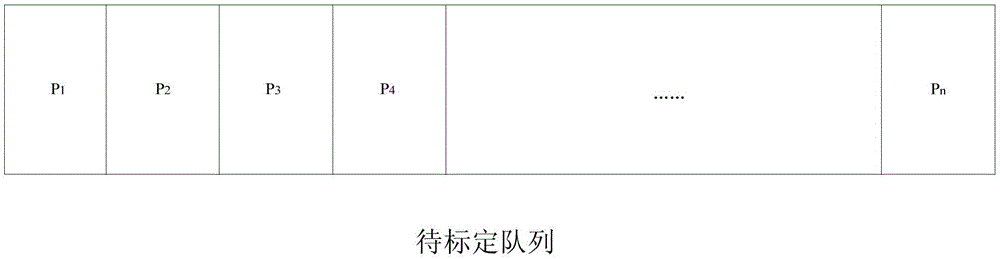

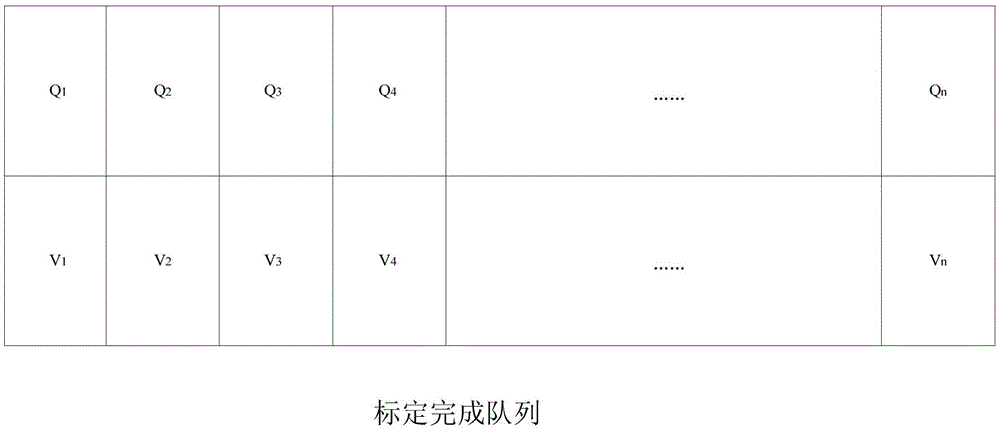

[0057] 1. The attenuation automatic calibration process is the preparation stage of the technical solution of the present invention. It must be at the forefront in time, and the control queue data is provided for the work of the latter two stages. This process only needs to be carried out once;

[0058] 2. Attenuation rapid control process, according to the target attenuation value used, with the help of the data queue provided by the attenuation automatic calibration to realize the function, every time the target attenuation value is updated or the change of the external optical path environment causes a deviation b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com