A high-efficiency electroplating pollution reduction device

A high-efficiency, end-face technology, applied in transportation and packaging, water/sewage treatment, water/sewage treatment equipment, etc., can solve the problems of complex wastewater composition, environmental health hazards, etc., to reduce labor hours, convenient operation, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

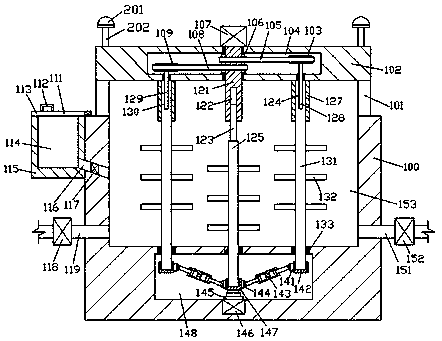

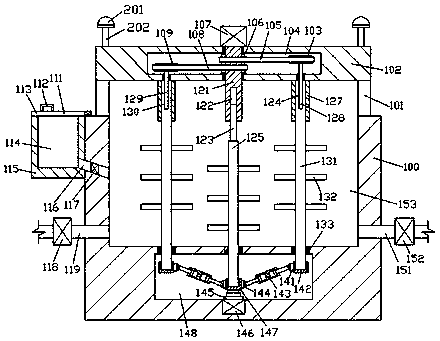

[0014] Combine below Figure 1-2 The present invention will be described in detail.

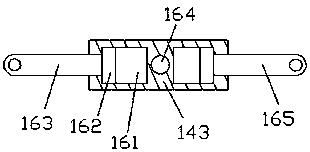

[0015] refer to Figure 1-2 According to an embodiment of the present invention, a high-efficiency electroplating pollution reduction device includes a main box body 100, a water storage cavity 153 is arranged in the top end surface of the main box body 100, and the top end surface of the main box body 100 The left and right side walls of the water storage chamber 153 are fixed with support rods 101, and the top of the support rods 101 is fixed with a drive seat body 102, and the left and right sides of the drive seat body 102 are provided with a transmission chamber 104, and the drive chamber 104 is A transmission shaft 121 extending up and down and protruding into the water storage cavity 153 is arranged in the center rotation fit, and the top extension end of the transmission shaft 121 protrudes from the top end surface of the drive seat body 102, and a drive motor 107 is installed in pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com