Sealing-free combined rotating ceramic paddle paper pulp stirring equipment

A non-sealed, pulp-free technology, which is applied to mixers with rotating stirring devices, mixer accessories, mixers, etc., can solve the problems of inconvenient operation for workers, easy to leave stirring dead angles, uneven single-axis rotating stirring, etc., to achieve Save manual work time, shorten pulp processing time, convenient and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in combination with specific embodiments.

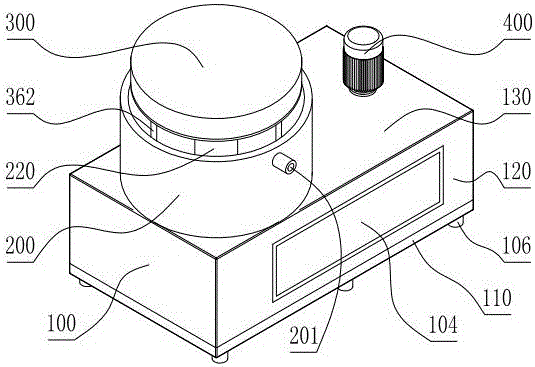

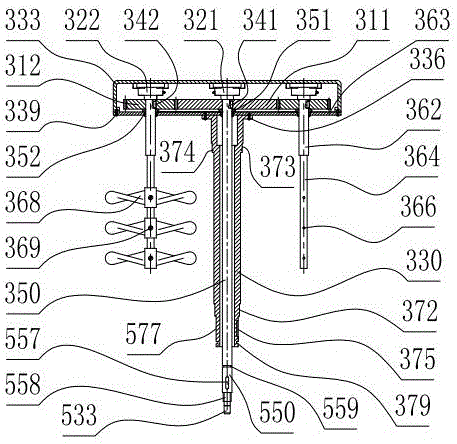

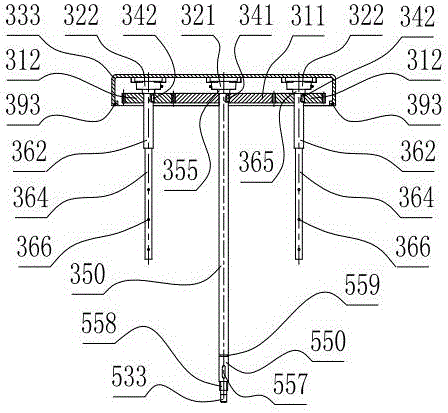

[0034] Such as Figure 1 to Figure 4 as well as Figure 5 and Figure 10 As shown, the non-sealed combined rotating ceramic paddle stirring pulp equipment includes: a base part 100, a pulp stirring tank 200, a combined rotating mechanism 300 and a motor 400, and the motor 400 and the pulp stirring tank 200 are all located above the base part 100, so The shell of the base part 100 described above is composed of the base bottom plate 110, the side plates 120 around the base and the base cover plate 130. Composition, combined rotating mechanism 300 includes driven shaft 350, revolving hollow shaft 330, gear box 333, gear box cover 363, central gear 311, rotation gear 312 and and rotation paddle shaft 362 and agitating blade 368, slurry tank outer cylinder Pulp feed pipe 201 and pulp discharge pipe 202 are arranged on 210, and as improvement: there is active bearing seat 244...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com