Design method for winding track of transformer

A design method and transformer technology, applied in design optimization/simulation, coil manufacturing, special data processing applications, etc., can solve the problems of cumbersome transformer winding steps and occupation of manual work time, so as to realize automatic operation and improve efficiency , The effect of reducing manual work time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

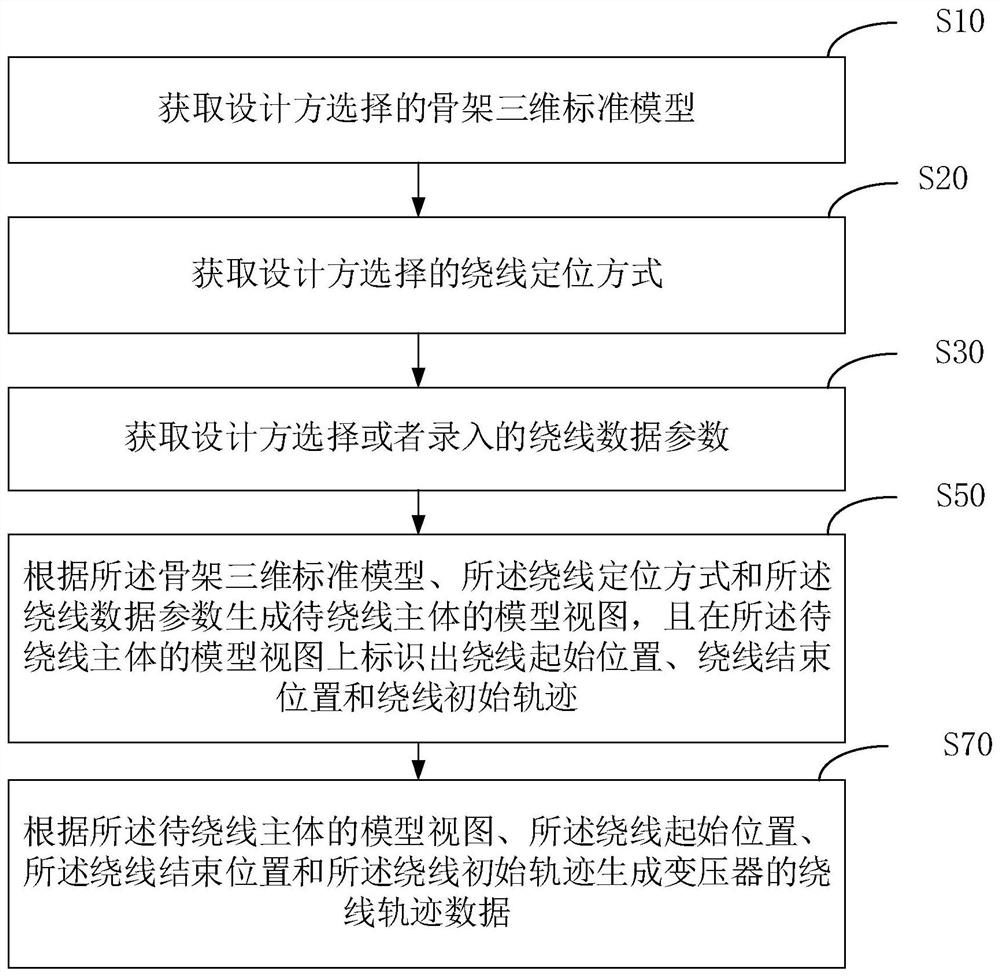

[0044] see figure 1 The present embodiment provides a design method of a winding track of a transformer, the design method is applied to a terminal, and the steps of the design method include: step S10, step S20, step S30, step S50 and step S70.

[0045] Step S10, acquiring the three-dimensional standard model of the skeleton selected by the designer.

[0046] Specifically, according to the instruction input of the designer, the skeleton type for the designer to choose is displayed on the display interface, wherein the skeleton type includes the selection of vertical skeleton and horizontal skeleton; Standard models to choose from.

[0047]In this embodiment, the 3D standard model of the skeleton is a skeleton model of standard specification stored in the database, and the selection of the standard 3D model of the skeleton is displayed on the interface. After obtaining the skeleton parameters required by the designer, jump directly to the next step. One step or enter the nex...

Embodiment 2

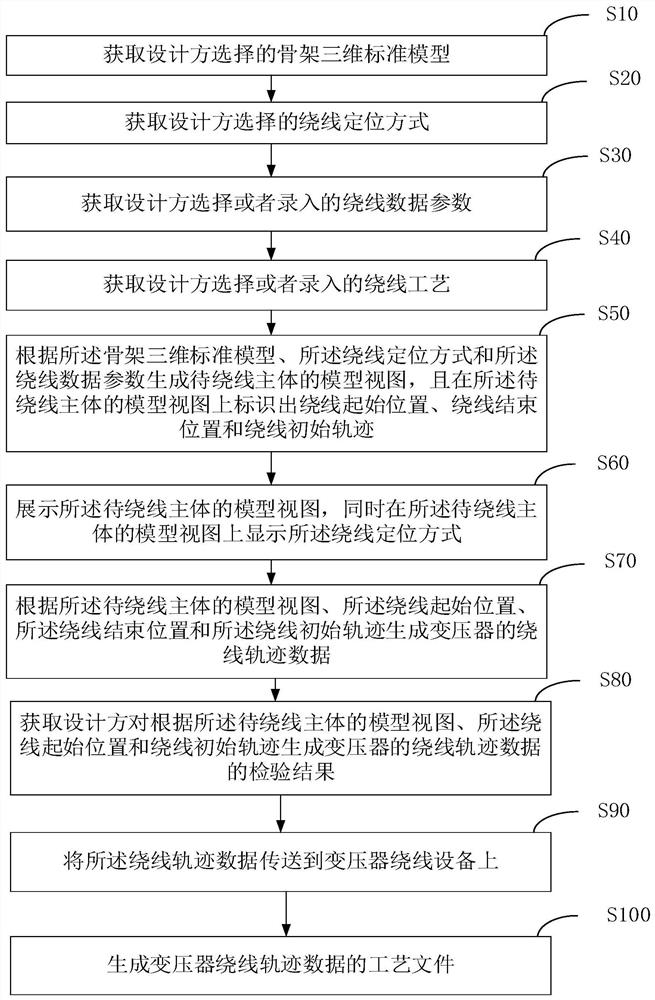

[0075] see image 3 , the present embodiment provides a method for designing a winding track of a transformer. The difference between the design method and Embodiment 1 is that step S40 is also included between step S30 and step S50; step S60 is also included between step S50 and step S70 ; After step S70, also include step S80, step S90 and step S100.

[0076] Step S40, obtaining the winding process selected or entered by the designer.

[0077] Specifically, the interface displays a winding process for the designer to choose or a port for the designer to input the winding process, which includes electrical requirements, peripheral size requirements, packaging requirements, lead wire requirements, insulation requirements and testing requirements, etc.

[0078] After obtaining the winding process selected or entered by the designer, inspect the winding process, and enter the next step after obtaining the confirmation instruction from the designer.

[0079] Step S60, displayi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com