A double-side glue sticking device

A technology of side sticking and equipment, which is applied in the field of double-side glue sticking equipment, can solve the problems of not being able to adapt to the development requirements of enterprises, reduce the production qualification rate, and different glue sticking standards, so as to reduce manual work time and improve production efficiency , to ensure the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

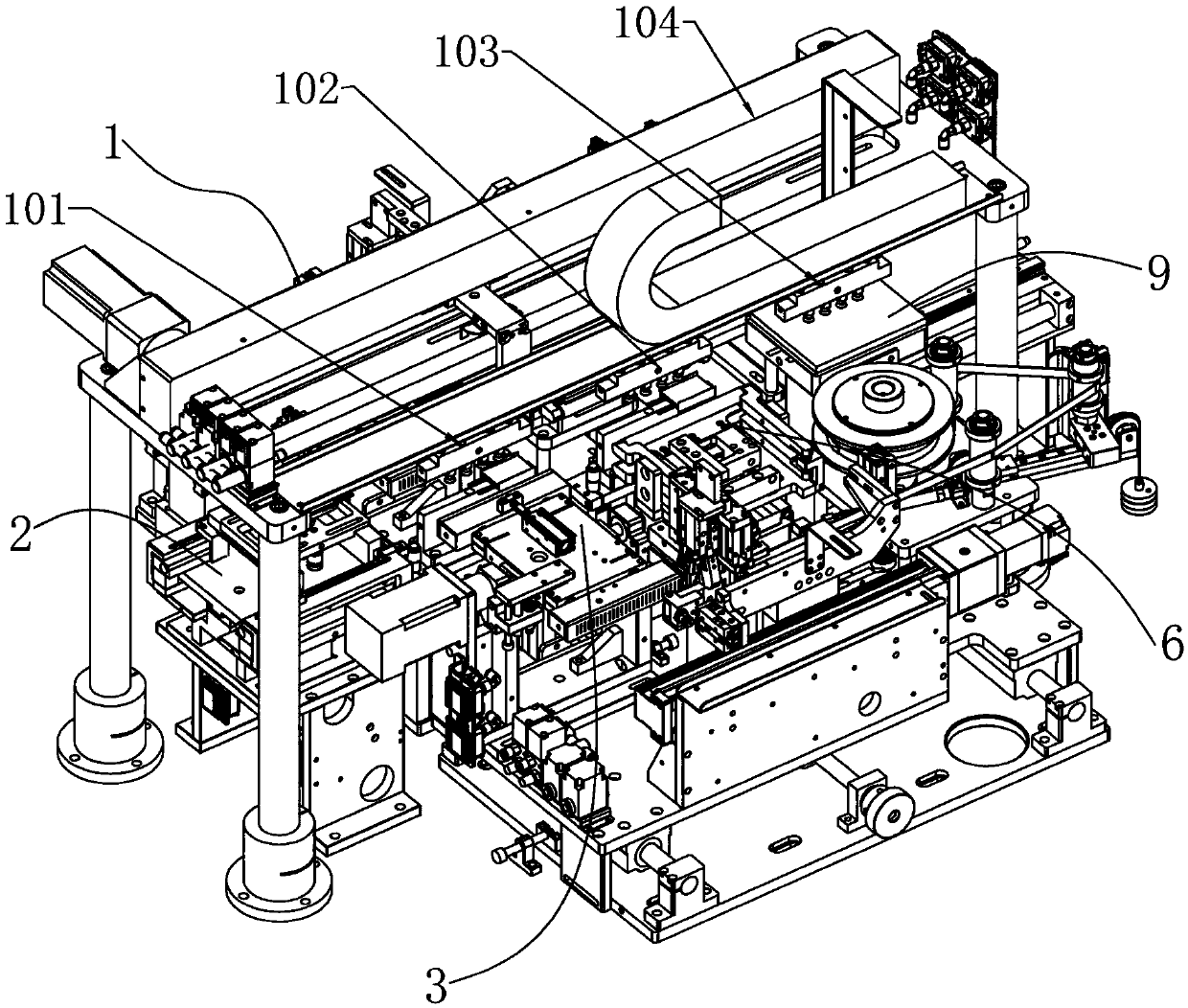

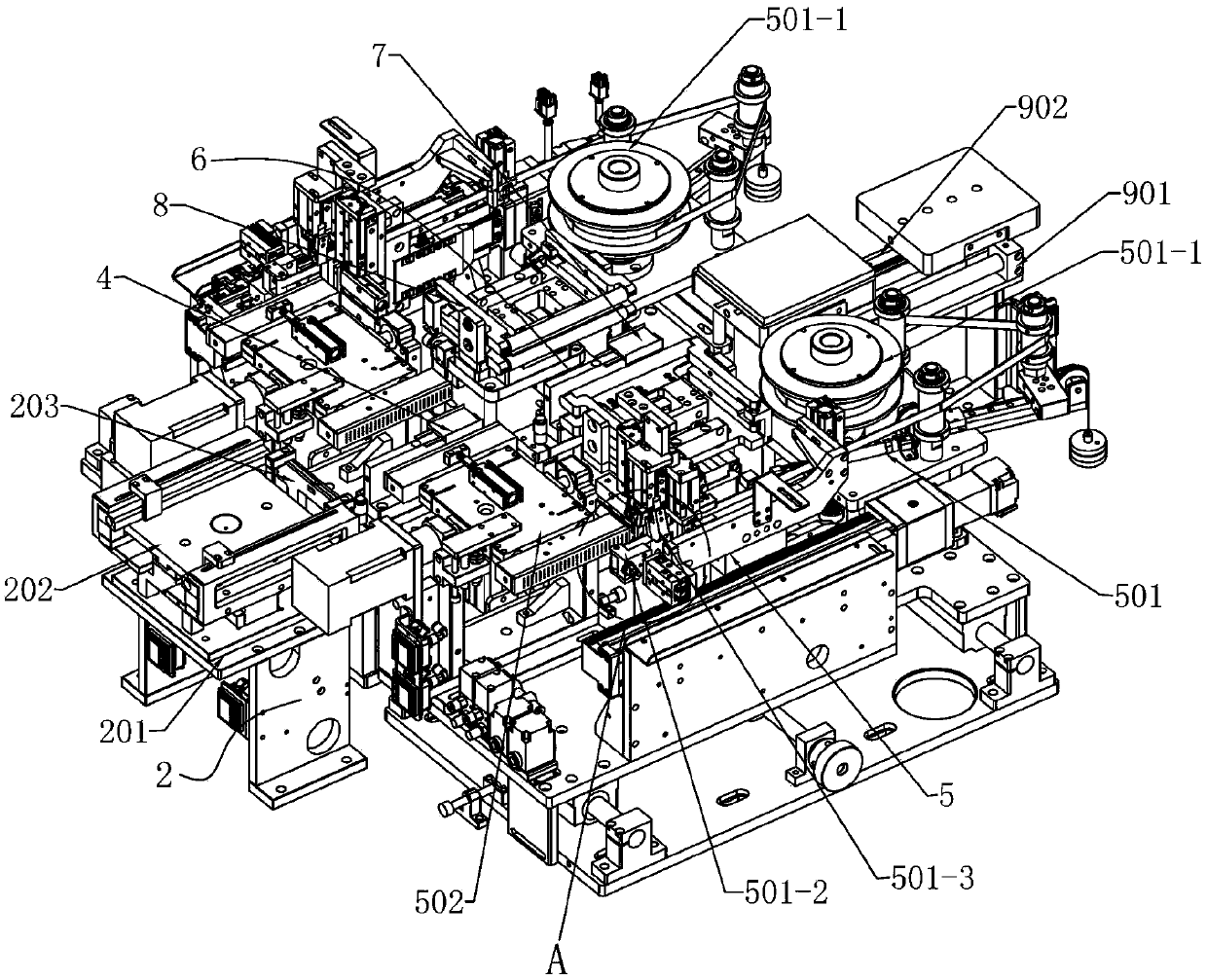

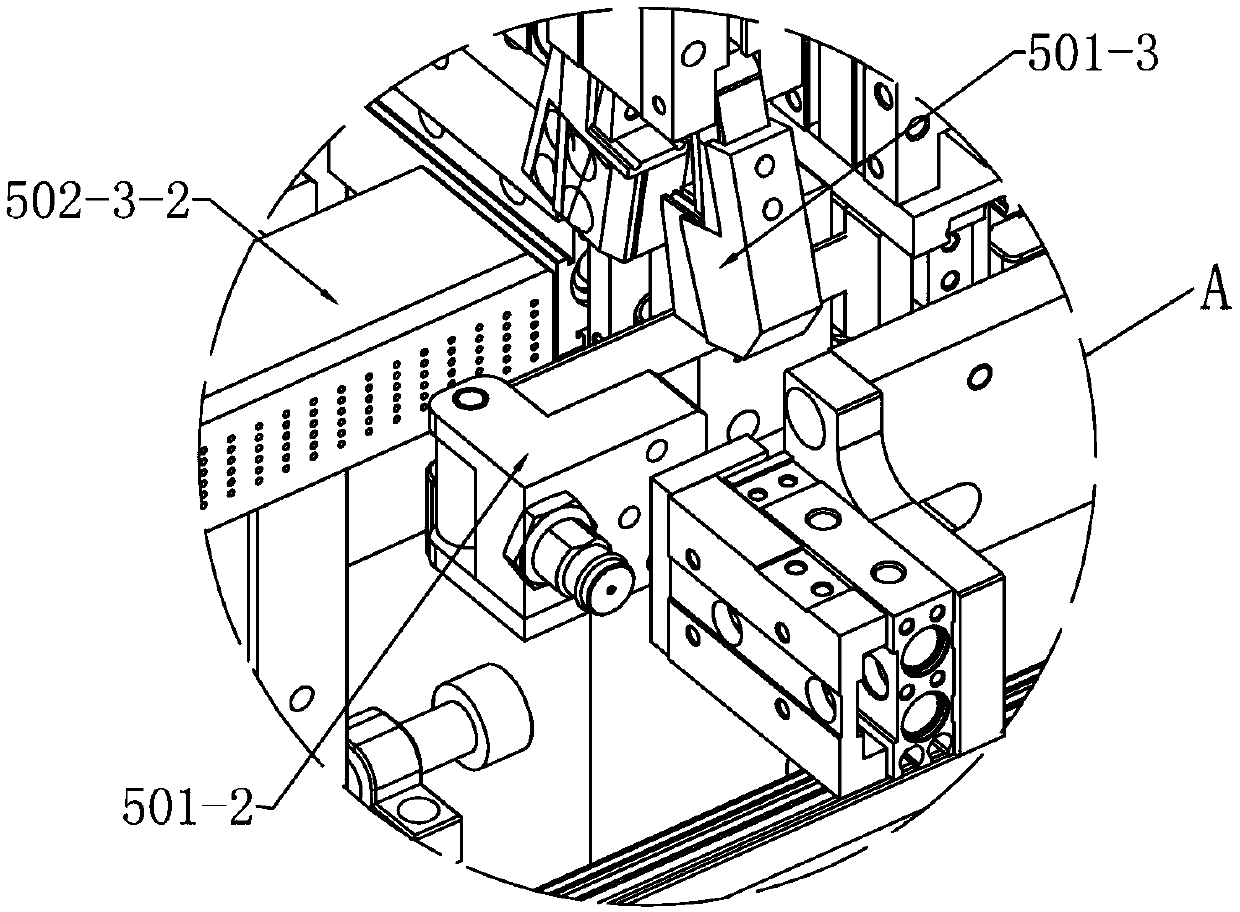

[0021] Specific implementation 1: Please refer to Figure 1 to Figure 6 In the embodiment of the present invention, a double-sided glue application device includes a moving unit 1, a shaping unit 2, a glue application unit 3, a pressing unit 6 and a blanking unit 9; the shaping unit 2, glue application unit 3, The pressing unit 6 and the blanking unit 9 are arranged side by side in sequence, and the moving unit 1 straddles and above the shaping unit 2, the glue applying unit 3, the pressing unit 6 and the blanking unit 9; the moving unit 1 It includes a supporting frame 104, a first manipulator 101, a second manipulator 102, and a third manipulator 103. The first manipulator 101, the second manipulator 102, and the third manipulator 103 are sequentially arranged side by side on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com