Drilling positioning device

A technology of positioning device and positioning plate, which is applied in the direction of drilling molds for workpieces, etc., can solve the problems of high construction risks, delays in the construction period of nuclear power plants, economic losses, etc., so as to reduce construction risks, shorten preparation time, and improve drilling success rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

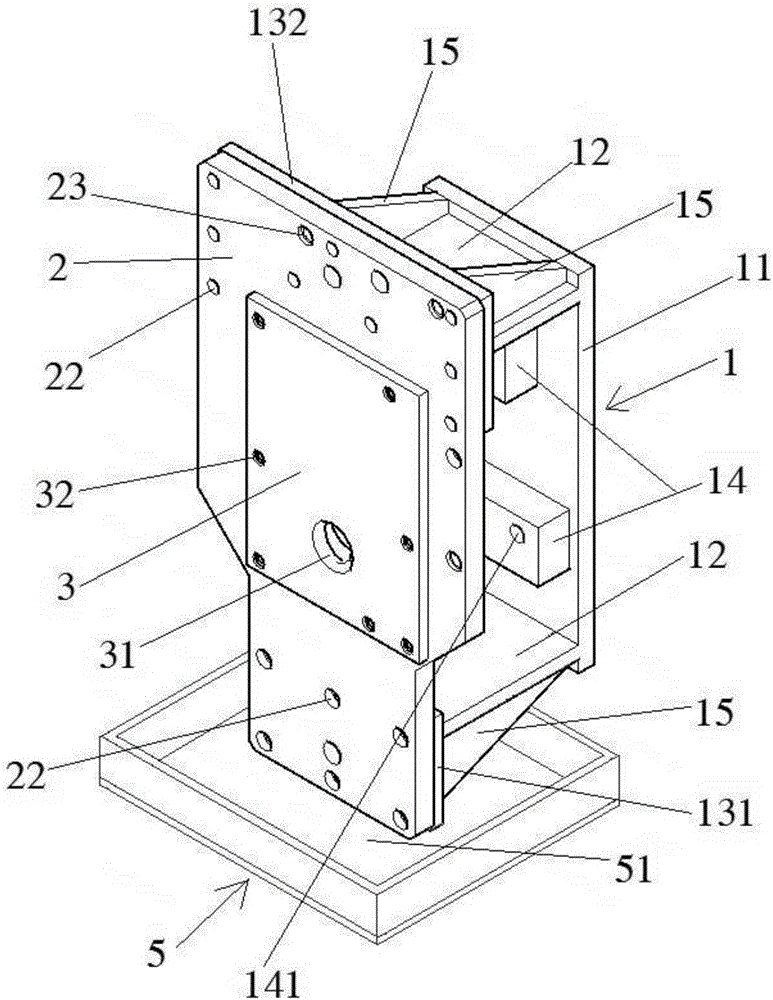

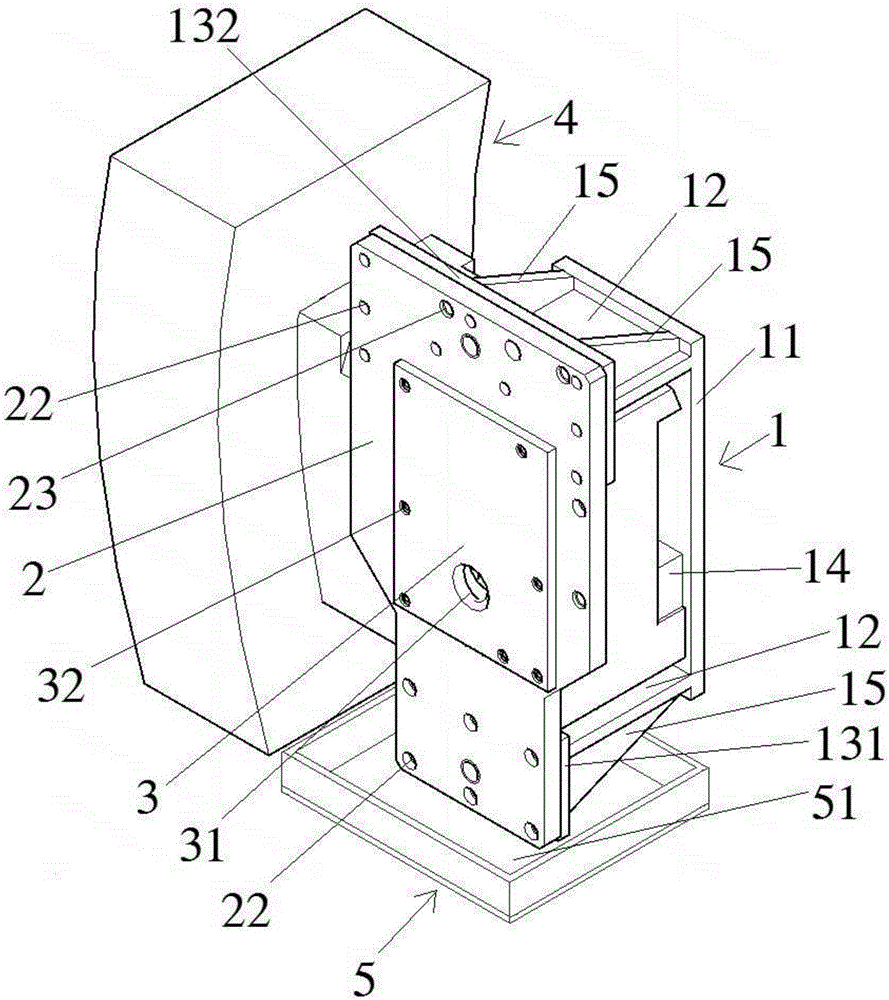

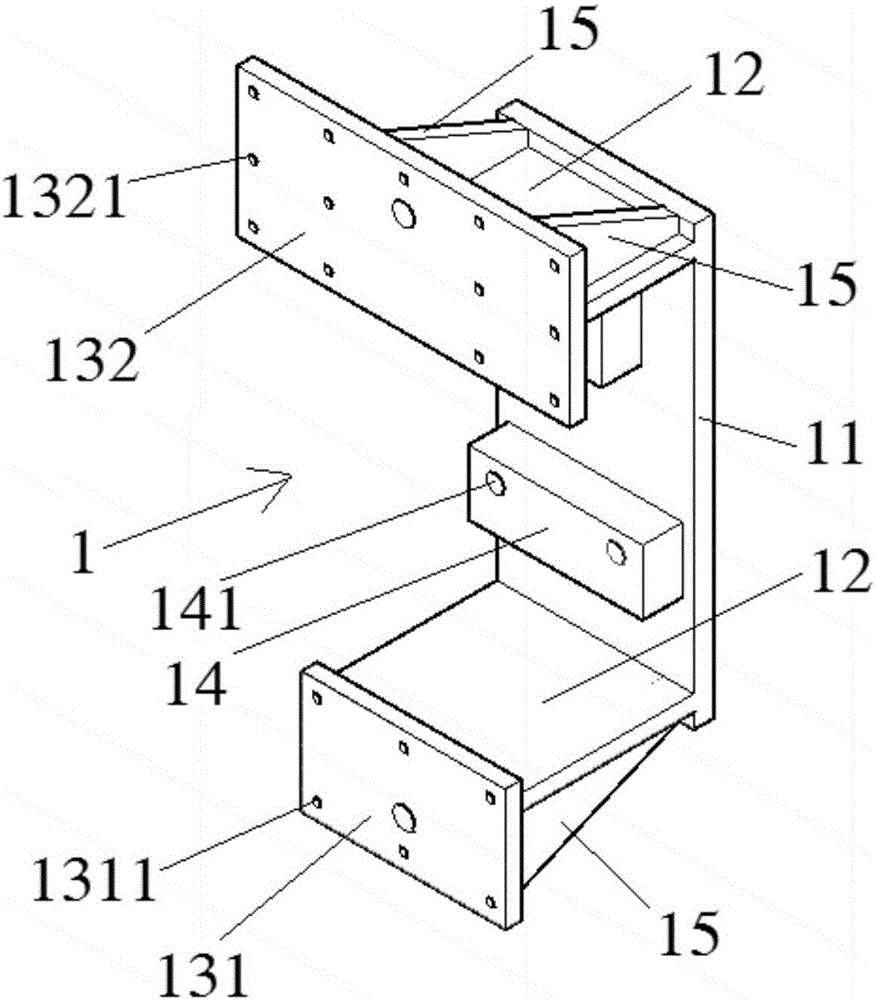

[0018] The following takes the pressure vessel insert as an example to be drilled, combined with Figure 1-6 The drilling positioning device of the present invention will be described in detail.

[0019] Such as figure 1 with 2 As shown, the drilling positioning device of the present invention includes a support structure 1 , a positioning template 2 and a drilling positioning plate 3 . Wherein, the supporting structure 1 comprises a supporting plate 11, two clamping plates 12 and two connecting plates, and the supporting plate 11 is provided with connecting holes (not shown) for installing positioning bolts (not shown in the figure); The fixed end of the plate 12 is connected to the support plate 11 by welding at the end of the support plate 11 to form a "concave" shape structure, and the connecting end of the clamp plate 12 is connected to the connecting plate. Preferably, as image 3 As shown, the connecting plate is divided into a first connecting plate 131 and a secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com