A construction method of a gear box for a self-elevating platform lifting system

A self-elevating platform and lifting system technology, applied in manufacturing tools, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of inability to assemble and weld in the area, high requirements for gearbox welding, and narrow space, etc., to achieve constructability, Easy assembly and guaranteed solderability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

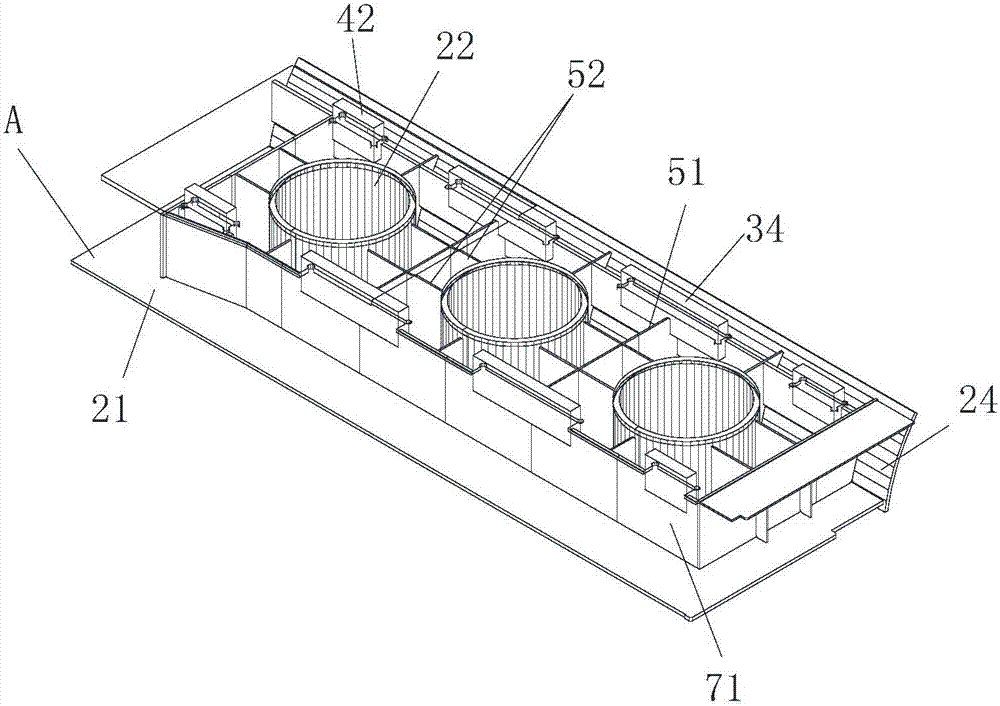

[0048] like figure 1 , Figure 8 and Figure 11 As shown, a construction method of the gearbox of the jack-up platform lifting system, the method divides the gearbox into two assemblies for construction, and the two assemblies are the gearbox main assembly A and the gearbox side cover assembly Establish B, specifically including the following steps:

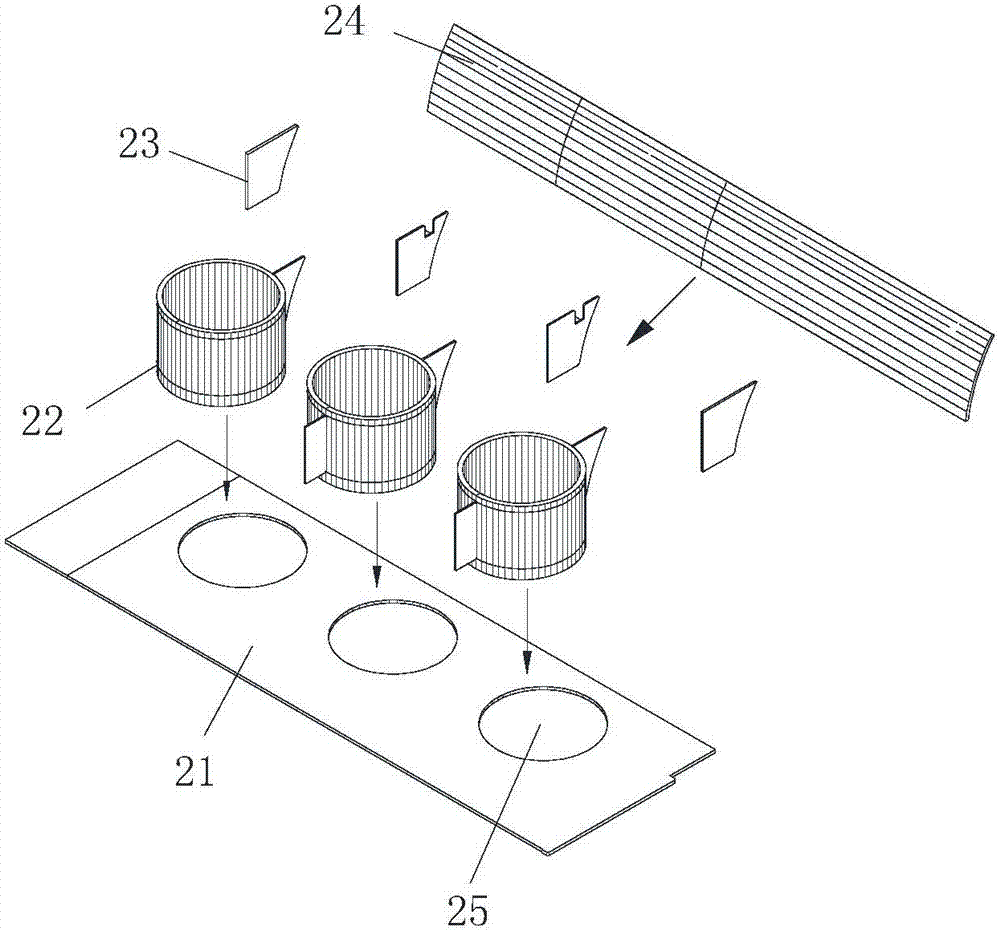

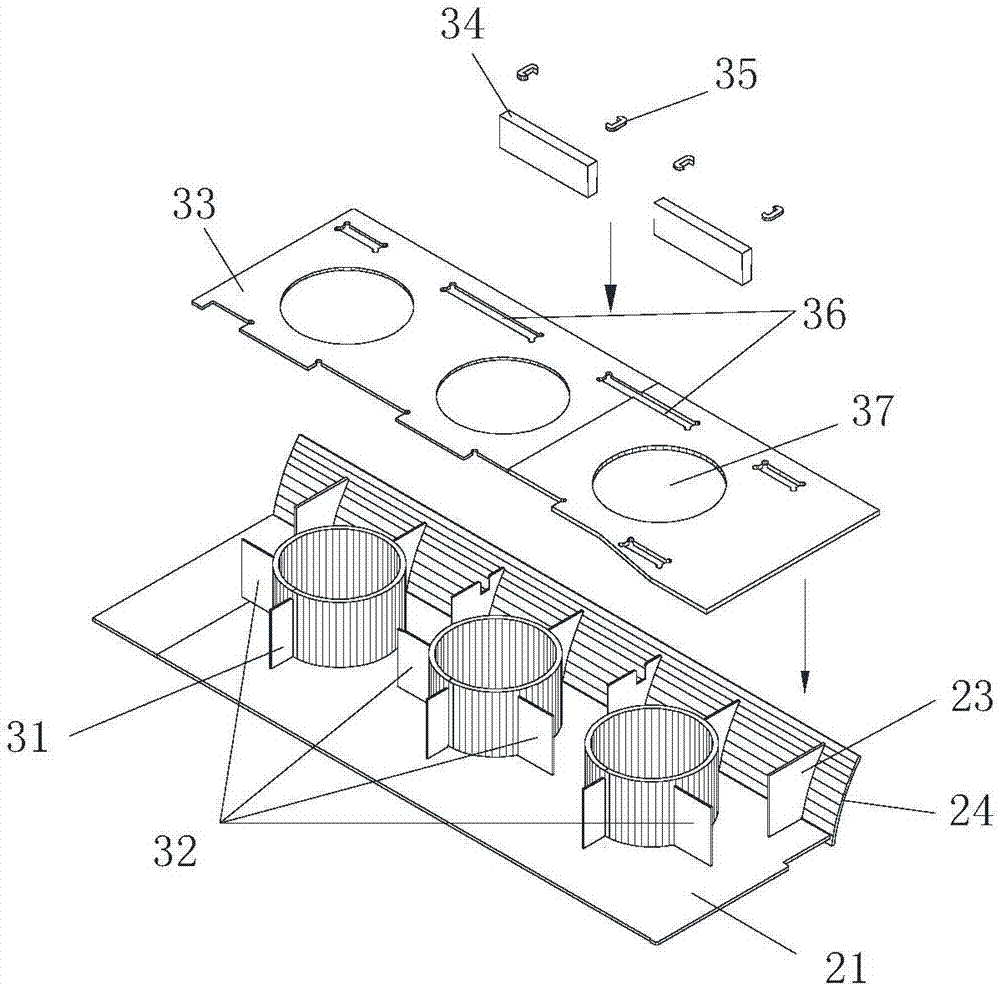

[0049] Step 1. Build the gearbox main body assembly A and the gearbox side cover assembly B respectively:

[0050] The main body assembly A of the gear box includes a middle vertical plate 21, a cylindrical bearing 22, a cover plate 33, a first circular arc plate 24, a horizontal bracket 23 arranged on the first circular arc plate 24, a side vertical plate 41, The first vertical partition 52, the first horizontal partitio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com