High-strength heat exchanger

A heat exchanger, high-strength technology, used in heat exchanger types, heat exchanger shells, indirect heat exchangers, etc., can solve problems such as product leakage, small contact surface between fins and baffles, swelling and separation, etc. Achieve the effect of increasing the contact area, long service life and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

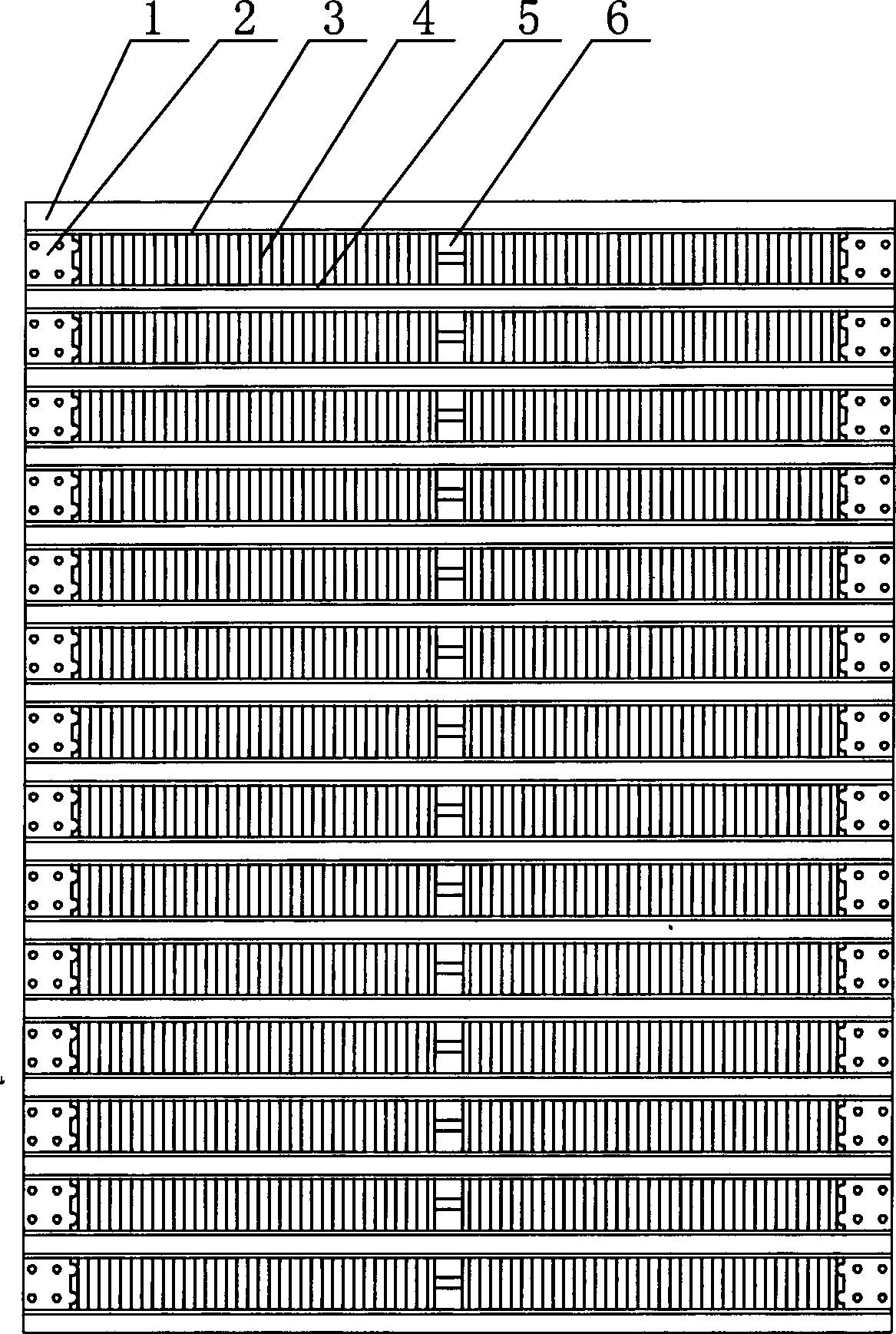

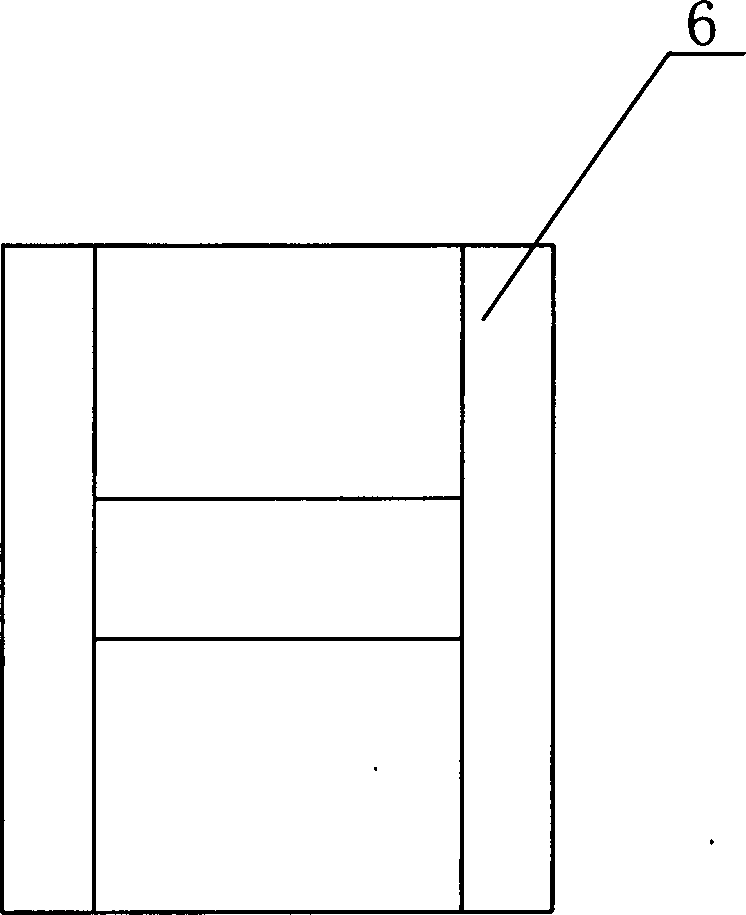

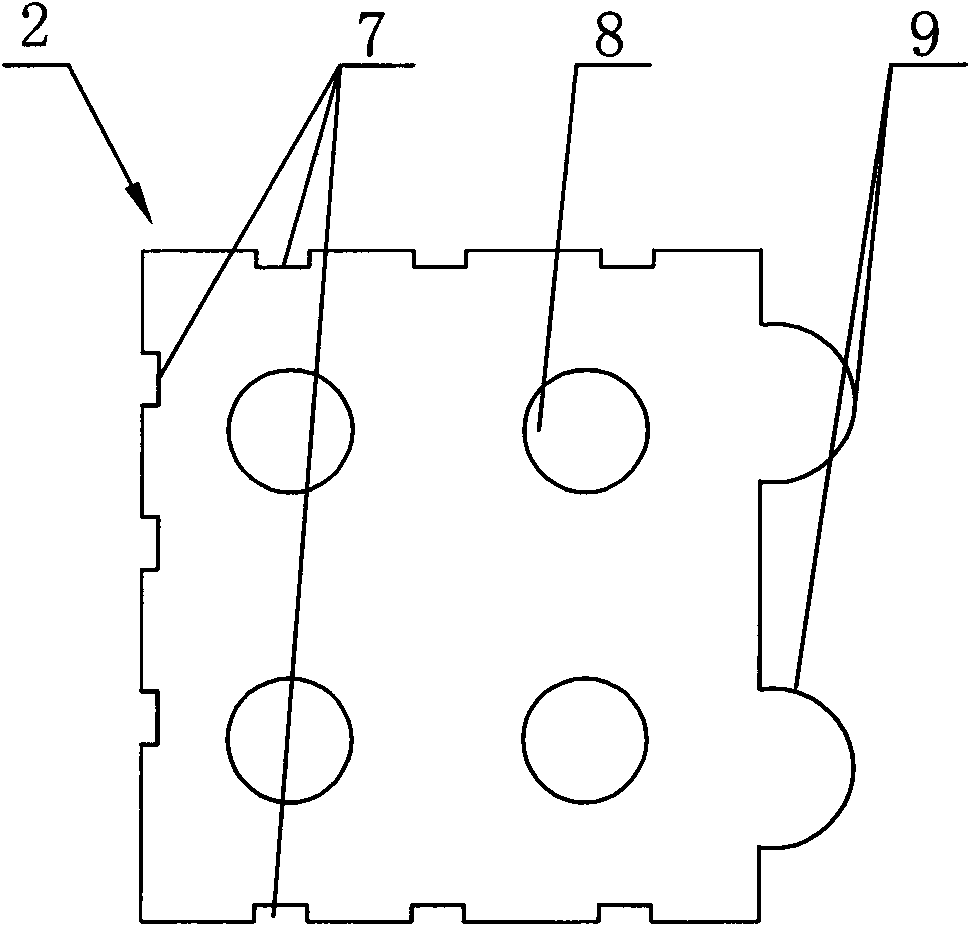

[0022] Such as figure 1 , figure 2 with image 3 As shown, the high-strength heat exchanger of this embodiment includes a cover plate 1 installed symmetrically up and down, and a plurality of heat exchange channels are installed between the cover plates 1. Between the plate 3 and the second partition 5, evenly arranged fins 4 are installed between the first partition 3 and the second partition 5, and seals 2 are installed at both ends of the fin 4, and are installed in the middle of the fin 4. There are "H" shaped ribs 6, "H" shaped ribs 6 adopt an integrated structure, the two sides of "H" shaped ribs 6 are in contact with fins 4 respectively, and the upper and lower end surfaces of "H" shaped ribs 6 are respectively connected to The first partition 3 and the second partition 5 abut; the "H" shaped rib 6 is installed in the middle of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com