Floating clamp

A floating fixture technology, applied in the direction of clamping, manufacturing tools, support, etc., can solve the problems of force concentration, irregular shape, waste products, etc., and achieve the effect of reducing force concentration and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

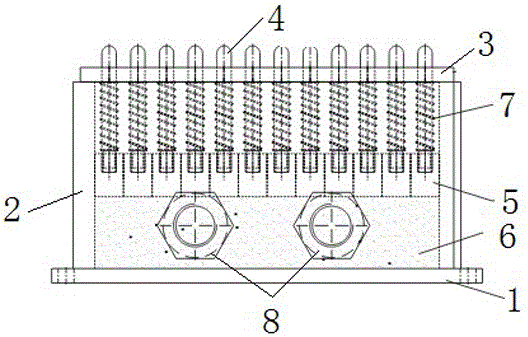

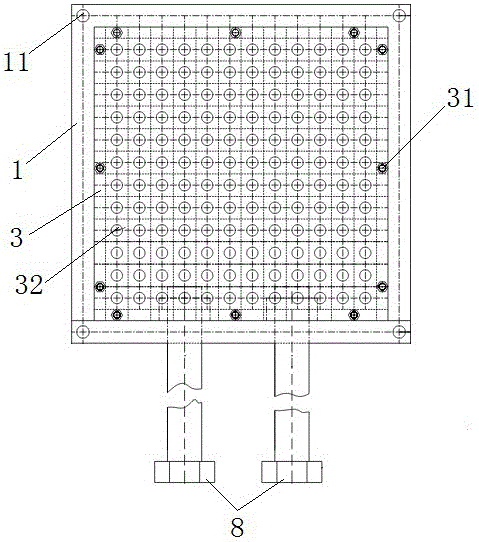

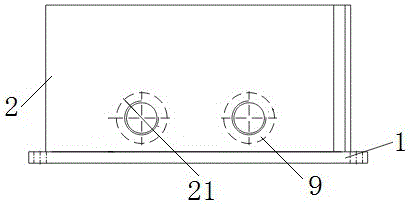

[0030] A specific embodiment of a floating fixture of the present invention, such as Figure 1 to Figure 2 As shown, it includes a pressure box and a plurality of axially floating ejector rods 4 . Such as image 3 and Figure 4 As shown, the pressure box body includes a base plate 1, a side wall plate 2 and a cover plate 3. The lower end surface of the side wall plate is welded on the base plate, and the outer surface of the base plate is the reference plane. Such as Figure 5 As shown, the base plate 1 is provided with a connecting hole 11 fixedly connected with the workbench on the periphery of the side wall 2, and the upper end surface of the side wall 2 is provided with first threaded holes 22 evenly distributed. 2. The four side panels are welded sequentially from the beginning to the end, and the welds between adjacent side panels are fillet we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com