Method for controlling ultra-deep air shaft reinforcing construction

A construction method and air shaft technology, which are applied in wellbore lining, shaft equipment, earthwork drilling, etc., can solve problems such as increased construction difficulty, loose walls, hidden safety hazards, etc., to extend service life, facilitate installation and disassembly, improve the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

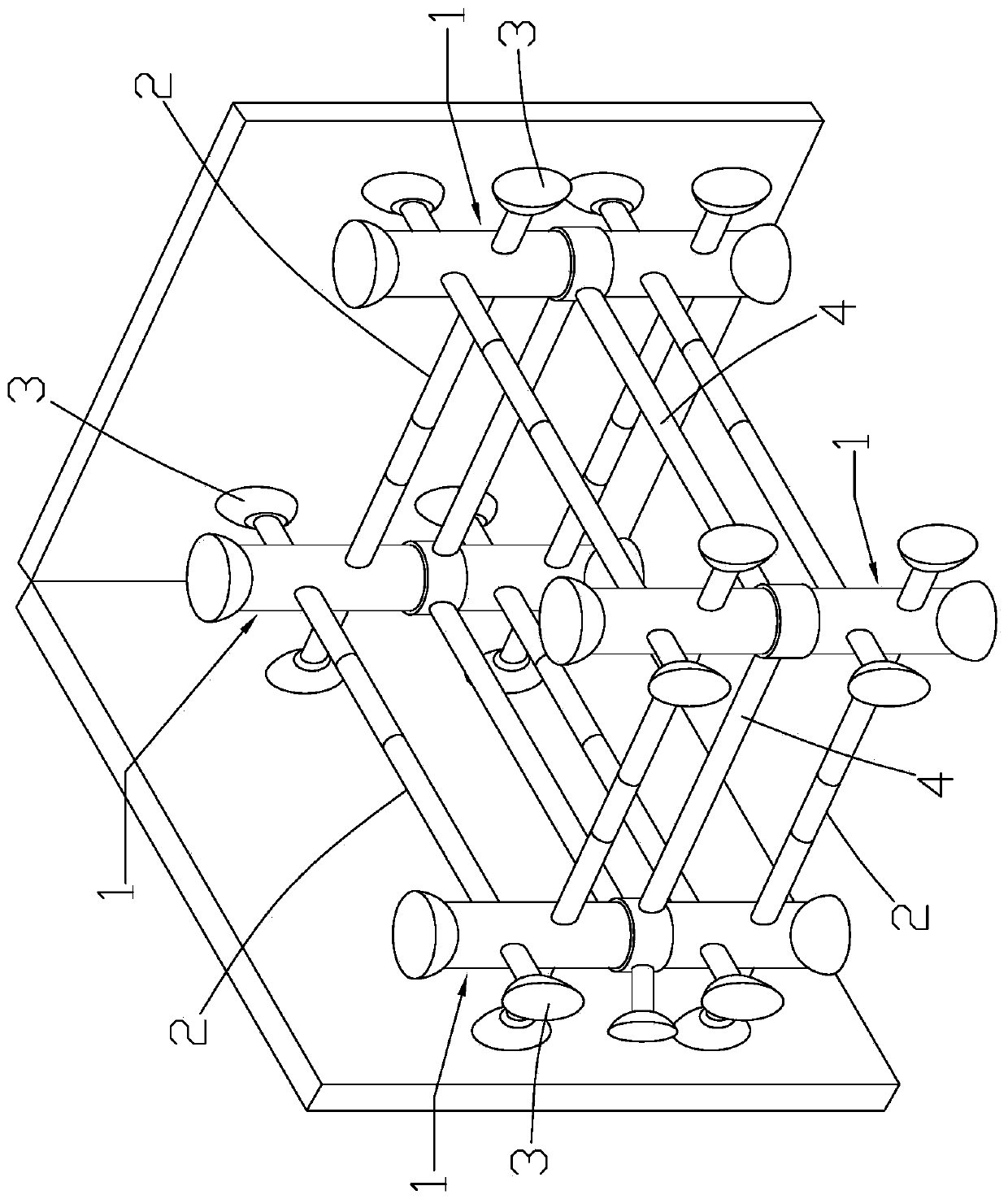

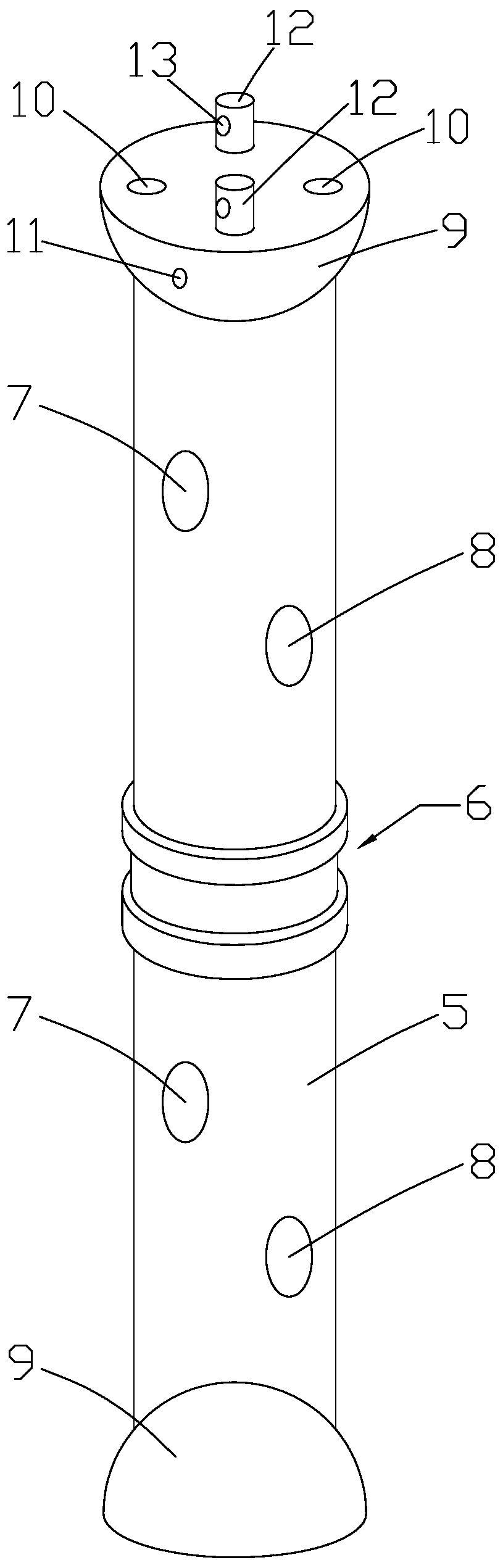

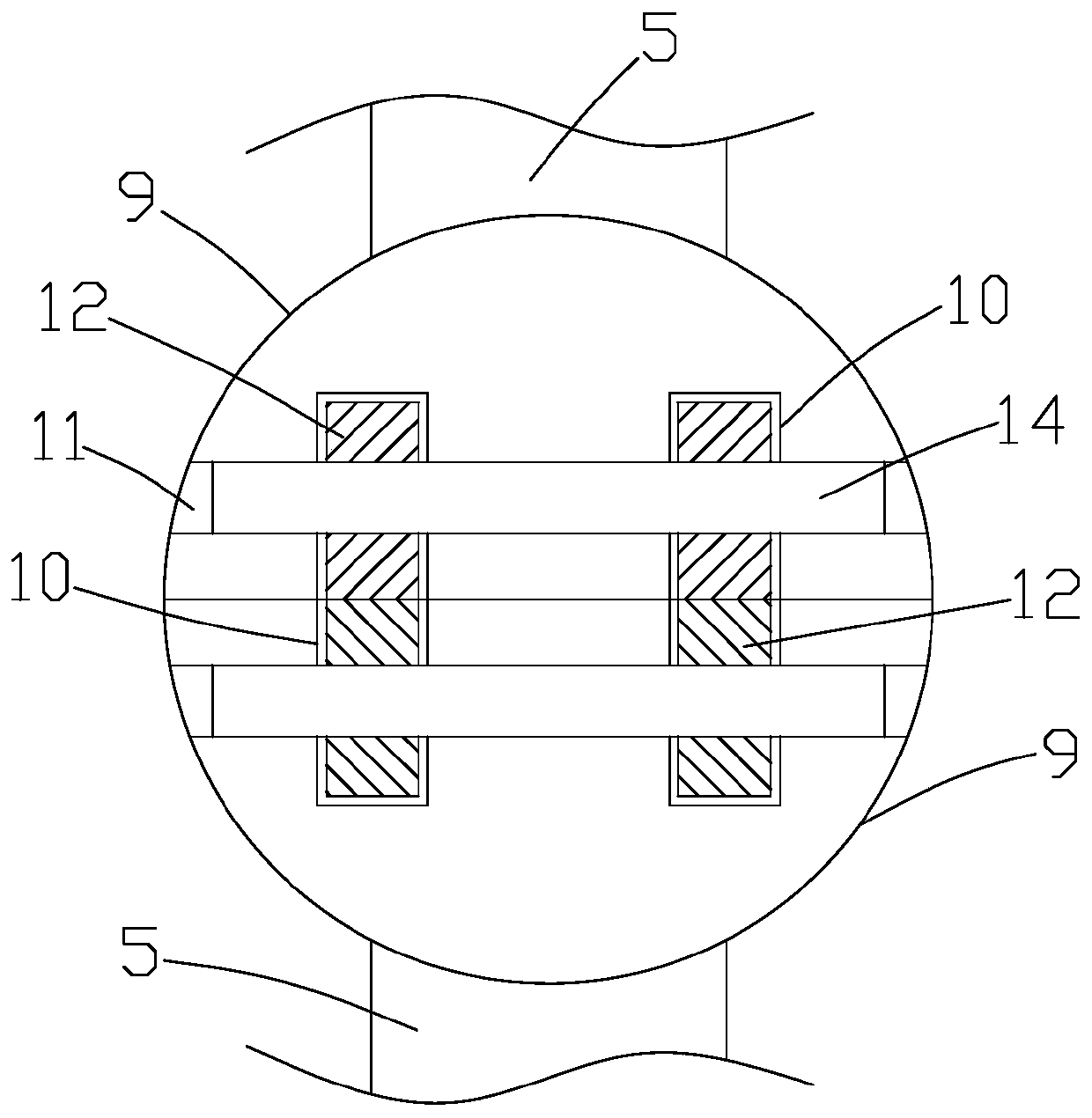

[0057] The present invention is a control construction method of ultra-deep wind shaft reinforcement control, comprising the following steps:

[0058] 1) Construction preparation

[0059] a. First, measure and set out the air shaft, measure the elevation, length and width of the air shaft, perform recheck measurement, and measure the verticality of each side of the air shaft, check with the design requirements, and use a drilling machine for the excess side Drill flat to ensure that the angle between each side matches the design requirements;

[0060] b. Then level the bottom surface and each side of the air shaft, remove the exposed stones on the bottom surface and sides, smooth it with mortar, use mortar to level the uneven bottom surface or side, and then use a tamping machine to level the air shaft The bottom and sides of the soil are compacted to compact the clay on the bottom or sides;

[0061] c. Then set up scaffolding in the air shaft, and fix the scaffolding with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com