Bidirectional mechanical transformer

A converter and mechanical technology, applied in portable drilling rigs, portable motorized devices, manufacturing tools, etc., can solve problems such as the trouble of replacing bit bits, easy scattering and loss of parts, and difficulty in ensuring the integrity of screwdrivers, etc., and achieves simple and compact structure, Convenient reversing and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

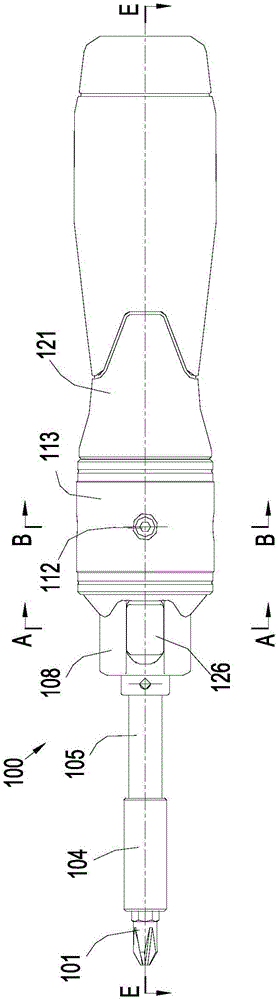

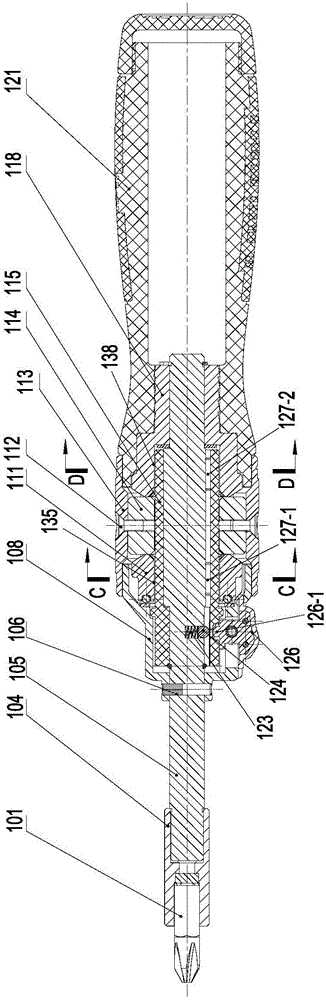

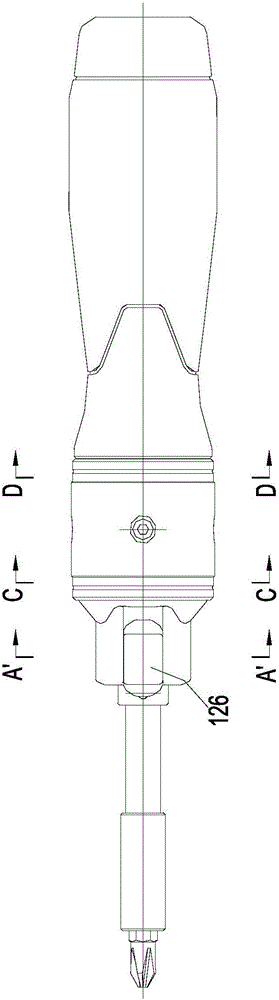

[0066] refer to figure 1 and figure 2 , a preferred embodiment is to apply the bidirectional mechanical converter of the present invention to a manual screwdriver 100, the screwdriver 100 is passed such as Figure 4 The transmission mechanism 120 shown realizes bidirectional double-speed transmission. The transmission mechanism 120 includes Figure 4 The transmission device 130 and the reversing device 110 shown can realize the switching of the rotation direction of the main shaft. Figure 5 and Figure 6 The structure and installation relationship of the transmission device 130 and the reversing device 110 are shown. The "two-way double-speed transmission" or "two-way transmission" of the present invention is relative to the input, that is, the handle is used as a rotating device, and its input force can be in any direction clockwise or counterclockwise. can be used effectively. The "reversible" in the present invention means that the output rotation direction of the m...

Embodiment 2

[0110] This embodiment is similar to the first embodiment, except that the reversing device 110 in the first embodiment is replaced by Figure 11C , 11D and Figure 12C , 12D The ratchet-pawl reversing device shown. A pawl seat is provided on the main shaft 105, and two reverse swingable pawls are arranged symmetrically on the pawl seat, namely Figure 11D and 12D Corresponding pawl seat 223 and pawls 224a and 224b of driving wheel 118, Figure 11C and 12C The center corresponds to the pawl seat 213 and the pawls 214 a and 214 b of the driven wheel 111 . There is an opening on the reversing element 215, and the two ends of the opening can push the ratchet to change the working position of the ratchet (that is, to set the rotation direction of the main shaft). Figure 11C and 12C Among them, the two ends of the opening of the reversing element 215 are 216a and 216b, Figure 11D and 12D Two ends of the middle opening are 226a and 226b. The inner circular surfaces of t...

Embodiment 3

[0118] This embodiment is similar to the first embodiment, except that the reversing device 110 in the first embodiment is replaced by Figure 13C , 13D and Figure 14C , 14D The brake pad type reversing device shown. Parallel grooves are slotted on both sides of the axis on the main shaft 105, and brake blocks are arranged in the grooves, that is, Figure 13D and Figure 14D corresponding to the brake blocks 324a and 324b of the driving wheel 118, Figure 13C and Figure 14C Corresponding to the brake blocks 314a and 314b of the driven wheel 111 . The outer end surfaces of the brake blocks 314a and 314b are inclined surfaces, and the two inclined surfaces face each other in a V shape. The reversing element 315 has an upper opening, and the opening end can push the outer end surface of the brake block to make the brake block expand and contract in the groove, thereby changing the working position of the brake block (that is, setting the rotation direction of the main sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com