Powder supply device

A powder supply device and powder supply technology, applied in the direction of manufacturing tools, additive manufacturing, additive processing, etc., can solve the problems of reducing the utilization rate of powder to be formed, waste of powder to be formed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

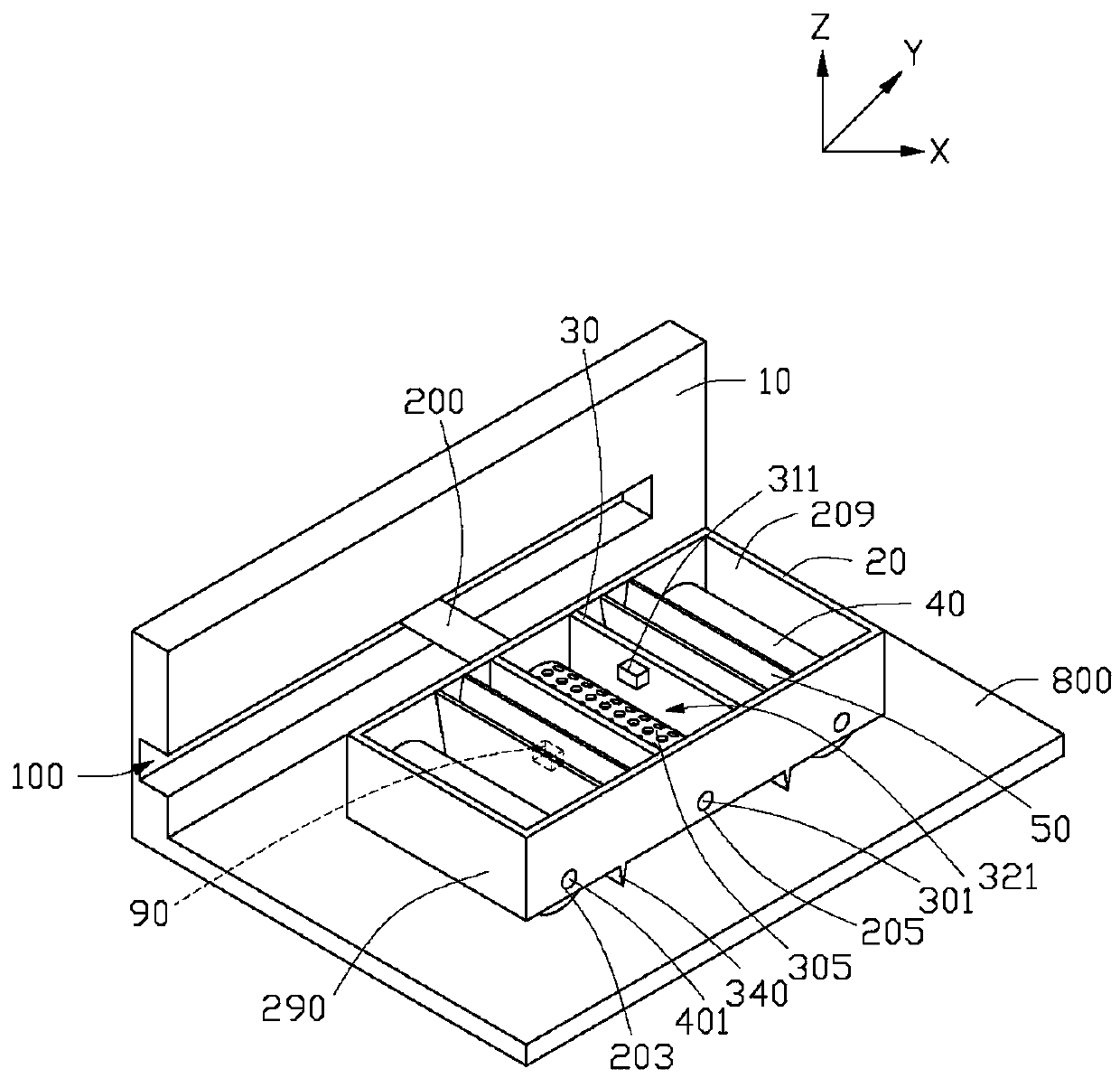

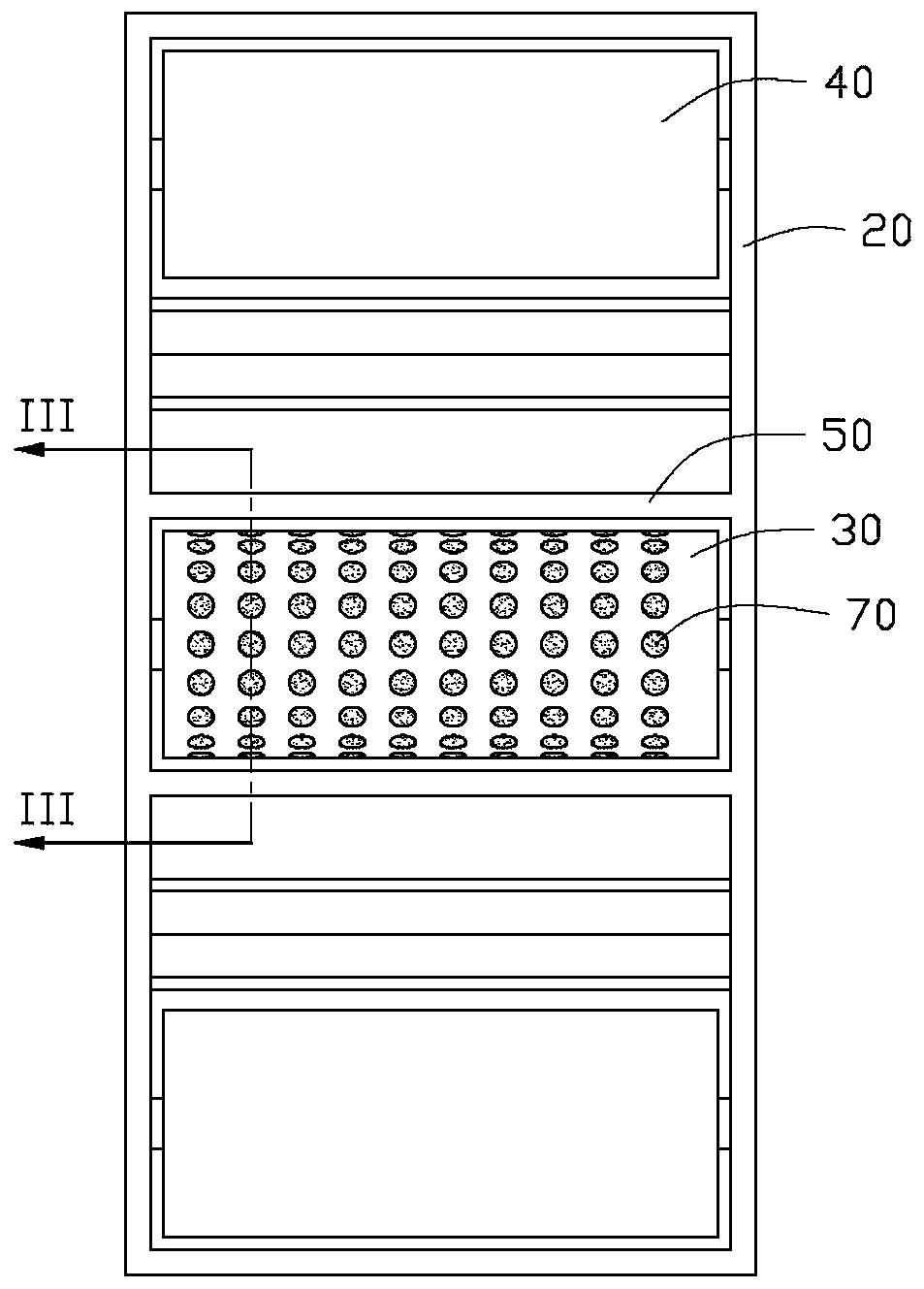

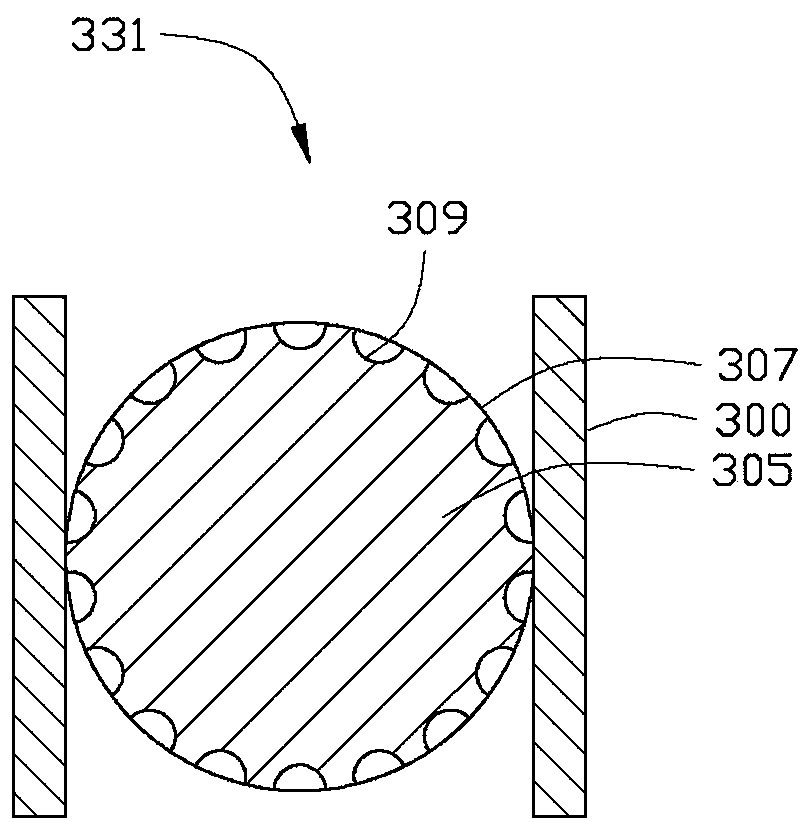

[0014] see figure 1 , A preferred embodiment of the powder supply device of the present invention includes a support portion 10 , a support member 200 and a powder supply vehicle 20 . In this embodiment, the supporting part 10 can be a wall of a building chamber in a 3D printer, and a forming area 800 is provided in the forming chamber of the 3D printer.

[0015] A guide part 100 is disposed on the support part 10, and the guide part 100 includes a preset track. In this embodiment, the preset track is a track parallel to the forming area 800 . The powder supply cart 20 is connected to the first end of the support member 200, and the second end of the support member 200 is slidably disposed in the guide portion 100, so that the powder supply cart 20 can move along the preset track, such as Control the powder supply vehicle 20 to move along the straight line where the track is located. In other embodiments, the track of the powder supply vehicle 20 can also be other tracks, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com