Oblong floating production storage and offloading (FPSO) ship

An oblong and rectangular technology, applied in the field of offshore floating production and storage vessels, can solve the problems of large bending load, shutdown, difficult separation of engineering and process modules from living areas, etc. The effect of good seakeeping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

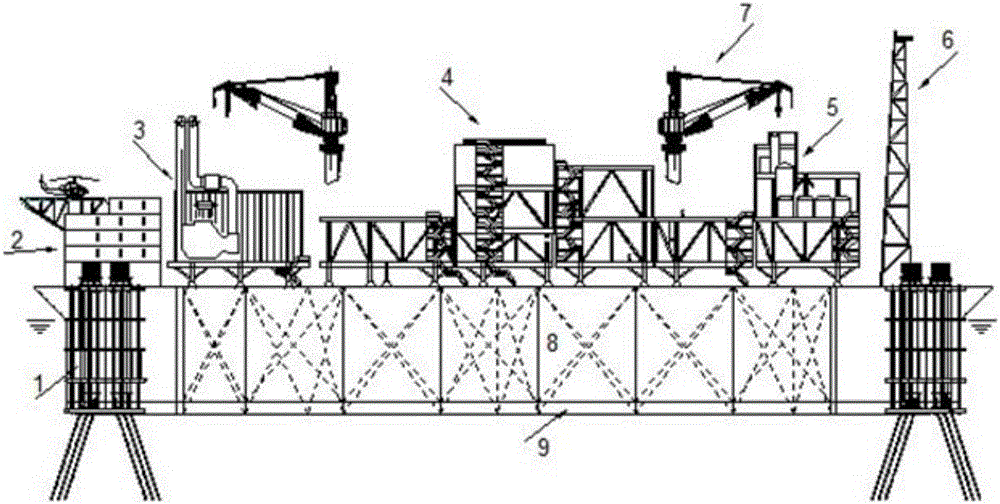

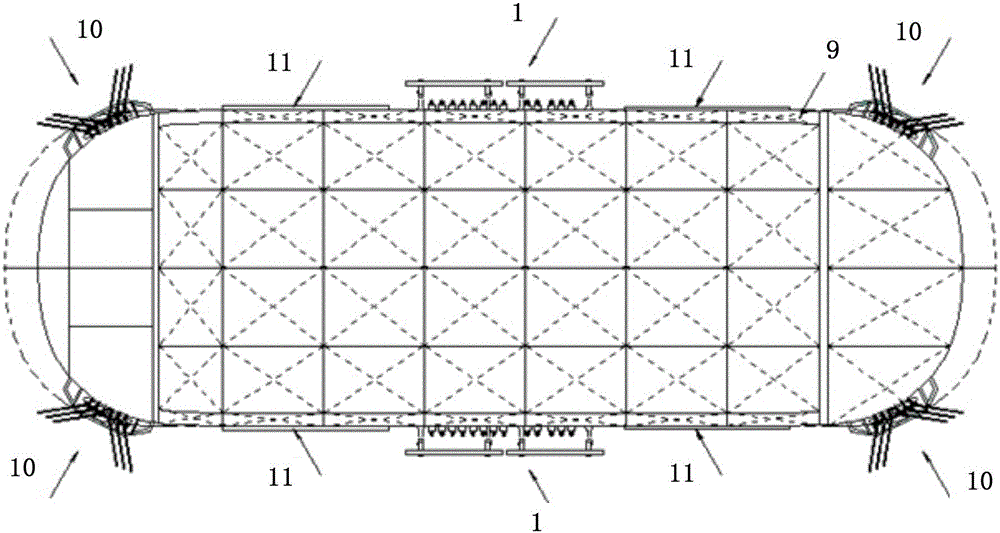

[0021] Example 1: Combining figure 1 and figure 2 , the cross-sectional shape (top view outline) of the hull of the present invention is an oval formed by a rectangle and two semicircles arranged at the two ends of the square, that is, the FPSO ship is composed of a rectangle and two semicircles The oblong main structure constitutes the hull, and the exterior of the FPSO ship is equipped with a multi-point mooring system. Specifically, a mooring point 10 is respectively arranged on the left and starboard sides of the bow and the left and starboard sides of the stern of the hull. There are four mooring points, each mooring point is provided with two groups of mooring lines at an angle, and each group of mooring lines contains 3 mooring lines, and the cable exit is flush with the bottom of the FPSO ship. The length of the telescopic mooring line realizes the rotation of the hull of the present invention within the range of 0° to 90°, which can ensure that the length direction ...

Embodiment 2

[0023] Embodiment 2: The two sides of the middle part of the hull are symmetrically provided with oil delivery devices 1 .

Embodiment 3

[0024] Embodiment 3: A bilge keel is provided on the bilge portion 11 in the area on both sides of the parallel center body of the hull. Usually the bilge keel is outwards along the direction of the bilge normal. Specifically, the bilge keel of the anti-rolling device is installed on the bilge 11 parallel to both sides of the midbody between the oil delivery device 1 and the mooring point 10 of the FPSO ship. Usually, the bilge keel is outward along the normal direction of the bilge. Increased stability of the FPSO vessel in sea waves.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap