Equipment for conveying with revolving suction belts

A suction belt and equipment technology, applied in the directions of sending objects, transportation and packaging, thin material handling, etc., to achieve the effect of maintaining constant friction, offsetting friction, and preventing changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

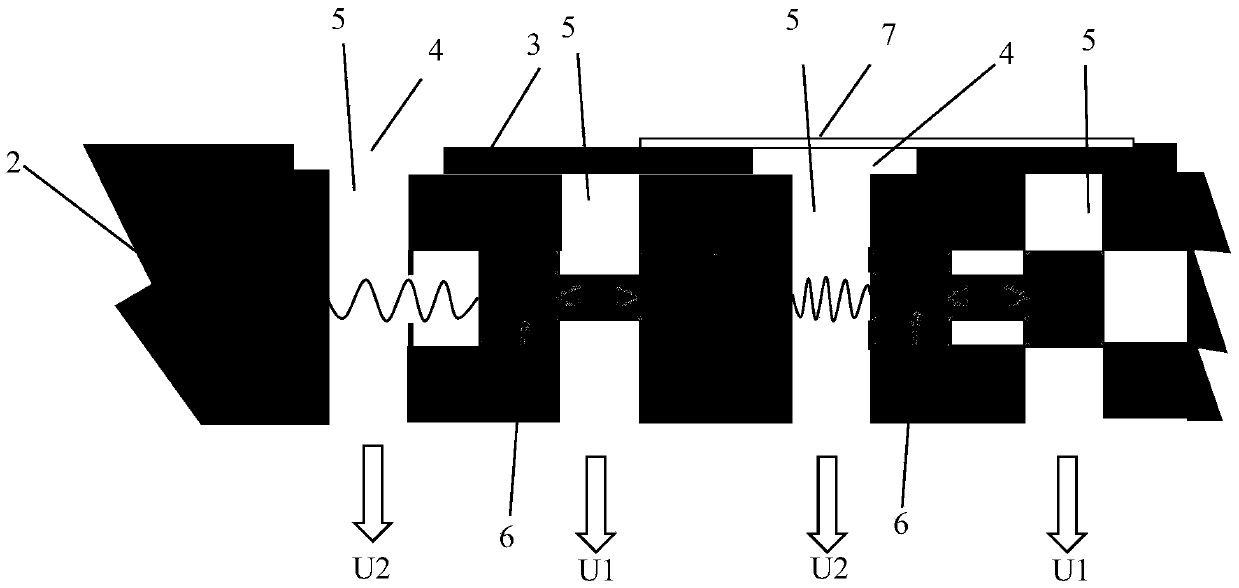

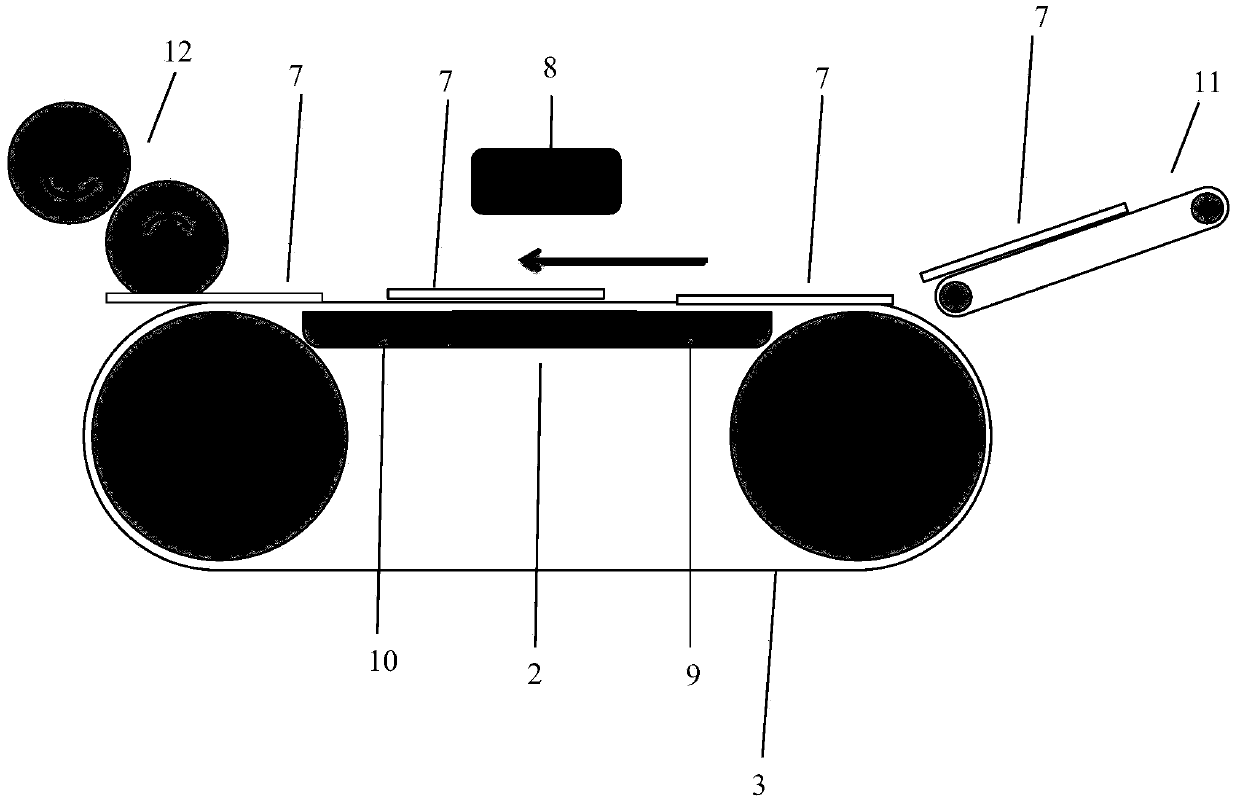

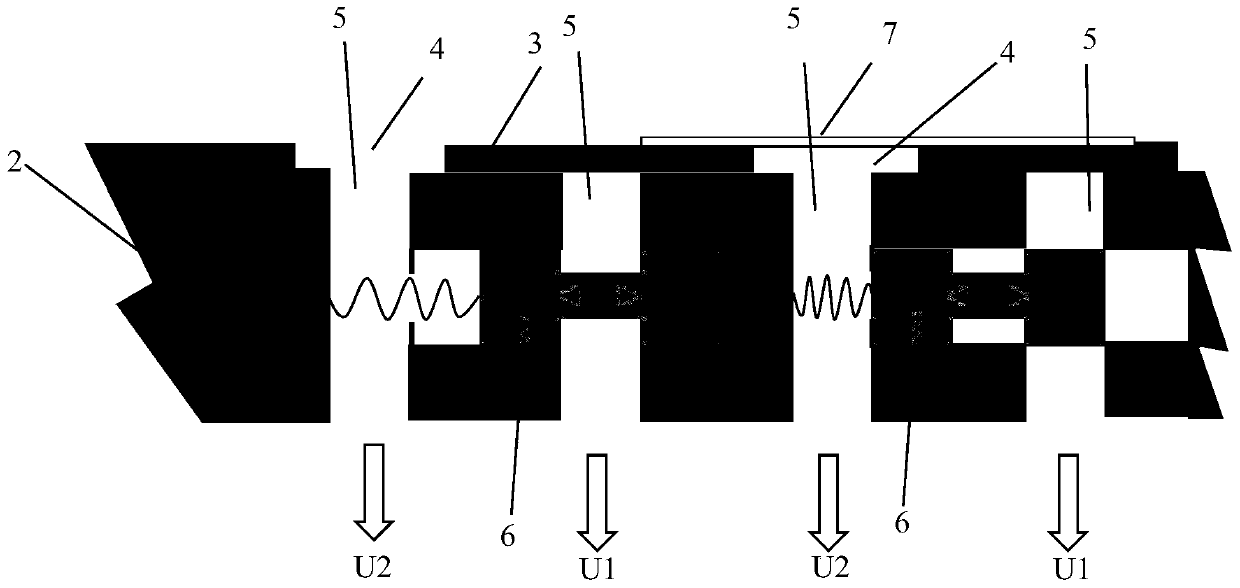

[0021] The sheets 7 are received in the feeder 11 and fed to the suction belt 3 . There, the sheet 7 is sucked through the suction opening 4 of the suction belt by the suction opening 5 of the suction box, and the sheet 7 is taken up by the revolving suction belt 3 . In this case, the first suction opening 5 is initially covered by the sheet 7 . In this case, the negative pressure U2 acts on the sheet 7 . Below the suction opening 5 covered by the suction belt 3 a negative pressure acts with a value U1. When the suction opening 5 of the suction box, which is not covered by the sheet 7 , is passed by the suction opening 4 of the suction belt, no underpressure is formed.

[0022] Below the suction opening 5 covered by the sheet 7 a negative pressure U2 builds up. This negative pressure tensions the spring-loaded switching element 6 and thus switches off the negative pressure U1 in the region of the suctioned sheet 7 .

[0023] In addition, the switching element 6 on the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com