Track crane for underground coal mines

A technology for rails and coal mines, which is applied to the field of rail hoists in underground coal mines, can solve problems such as low manpower installation efficiency, coal mine safety accidents, and complex structures, and achieve the effects of improving safety and practicability, preventing safety accidents, and stabilizing equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

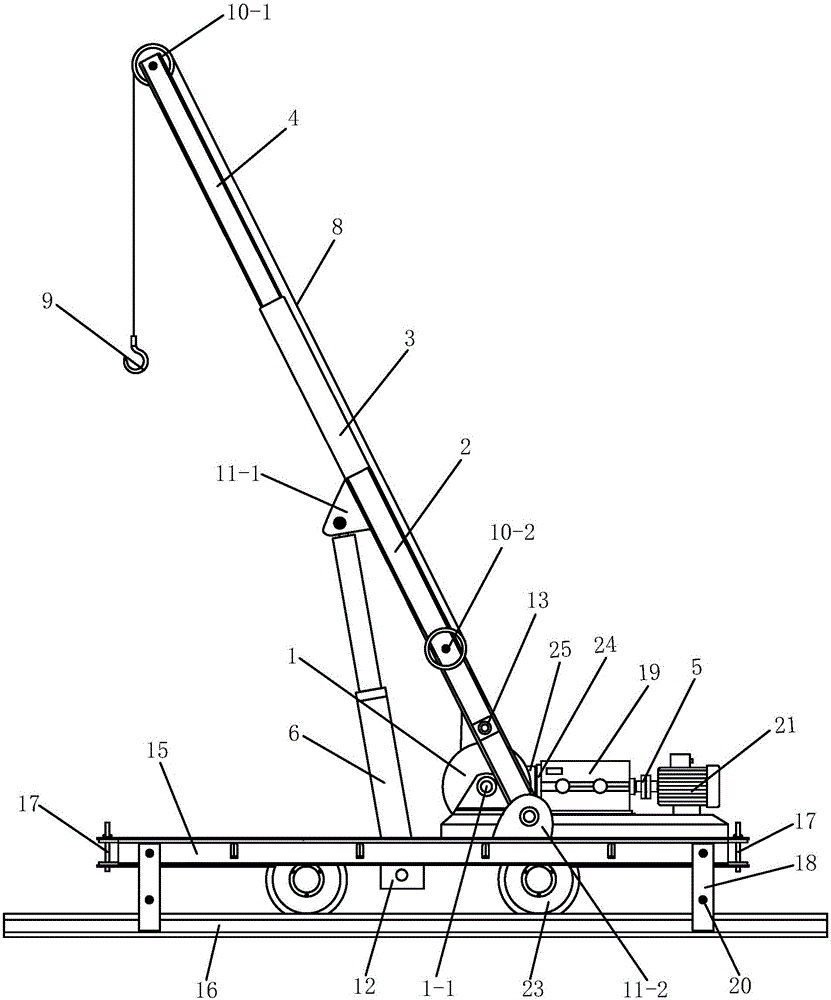

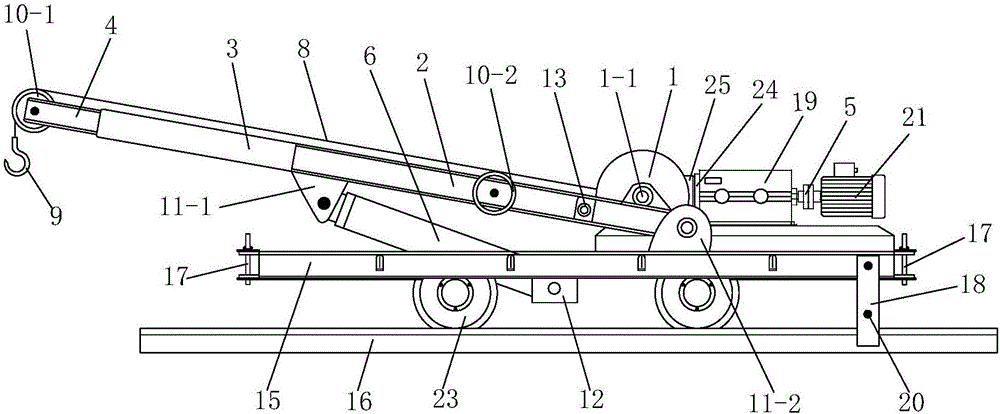

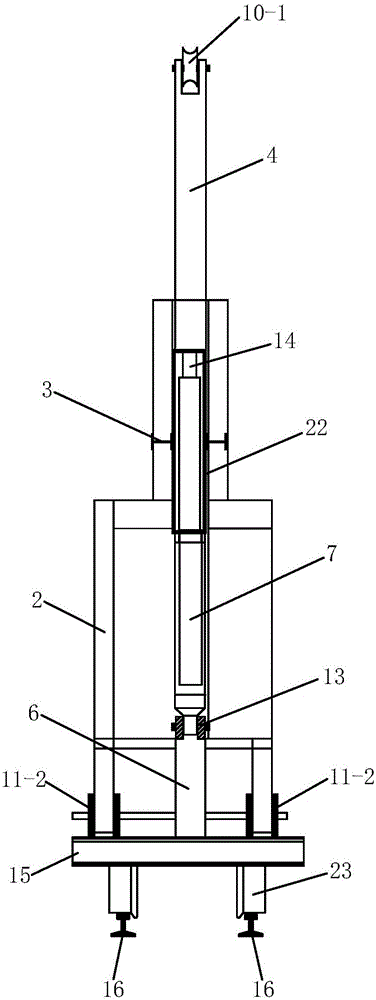

[0039] Such as Figure 1 to Figure 4 As shown, the present invention includes a flatbed car 15 that can move along the track 16 laid underground in the coal mine, and the bottom of the flatbed car 15 is equipped with traveling wheels 23 and a rail clamp 18, and the bottom of the rail clamp 18 is connected with the track 16 , the flatbed truck 15 is equipped with a boom device, a reel 1, a boom support mechanism 6 for supporting the boom device and a reel driving mechanism for driving the reel 1 to rotate, and the boom device includes Support frame 2, bracket 3, telescopic arm 4 and jack 7, the lower end of described bracket 3 is fixedly connected with the top of support frame 2, and the inner wall of described bracket 3 is provided with draw-in groove 22, and described telescopic arm 4 The lower end of the jack extends into the bracket 3 and can slide along the slot 22. One end of the jack 7 is connected to the support frame 2, and the other end of the jack 7 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com