Adhesive tape easy to stretch and remove, and manufacturing method thereof

A tape and removal technology, applied in the direction of adhesives, film/flake adhesives, etc., can solve the problems of fire in the flammable part of the battery of electronic products, potential safety hazards, weak anti-static protection performance, etc., to avoid damage or even fire. Accidents, the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0048] Preparation

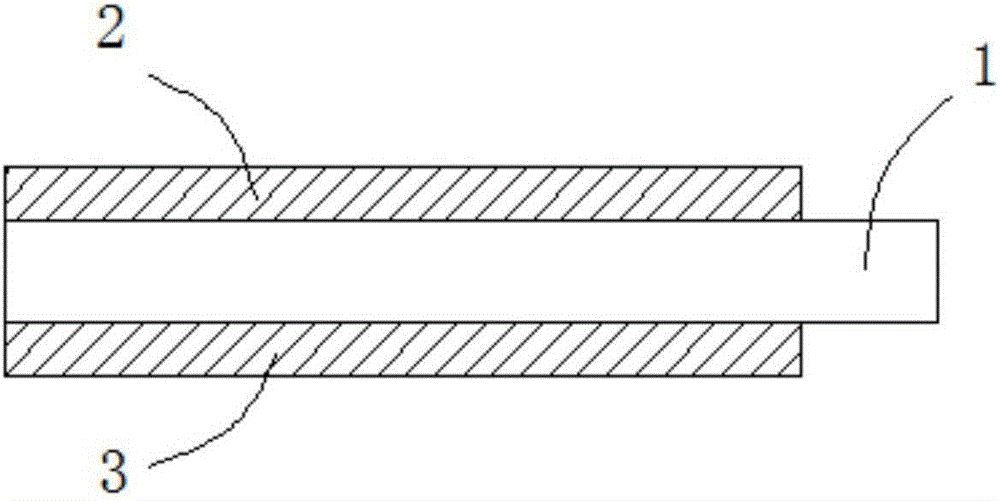

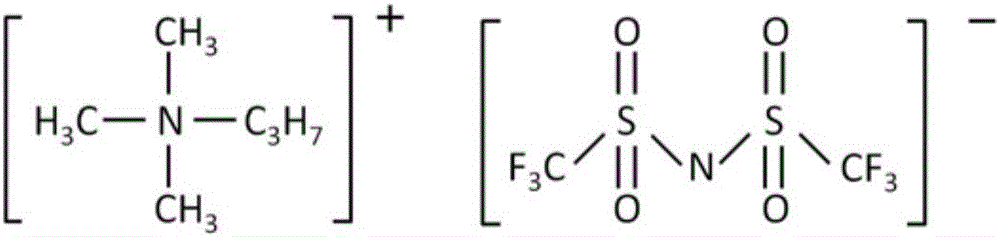

[0049] 1. Add bistrifluoromethanesulfonimidated trimethylpropyl quaternary ammonium salt (N 1113 NTf 2 ), and mix uniformly, coat the polyurethane with the substrate to form a coating, peel off the coating to form the base layer 1, and the width of the base layer 1 is 10mm;

[0050] 2. Coating the first pressure-sensitive adhesive layer 2 and the second pressure-sensitive adhesive layer 3 on both sides of the base layer 1 to form a stretchable removable tape;

[0051] When an antistatic additive is added to the first pressure-sensitive adhesive layer 2, the pressure-sensitive adhesive and bistrifluoromethylsulfonimidated trimethylpropyl quaternary ammonium salt (N 1113 NTf 2 ) is mixed and then coated; when antistatic additives are added in the second pressure-sensitive adhesive layer 3, the pressure-sensitive adhesive and bistrifluoromethylsulfonimidated trimethylpropyl quaternary ammonium Salt (N 1113 NTf 2 ) mixed before coating.

[0052] Among...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com