An automatic feeding device for electric arc furnace sealed inclined rail

An automatic feeding device and electric arc furnace technology, applied in the field of electric arc furnaces, can solve the problems of inability to achieve fully enclosed feeding, unfavorable energy saving and consumption reduction for enterprises, and energy loss, etc., to reduce energy consumption, facilitate maintenance, and improve water leakage and deformation problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

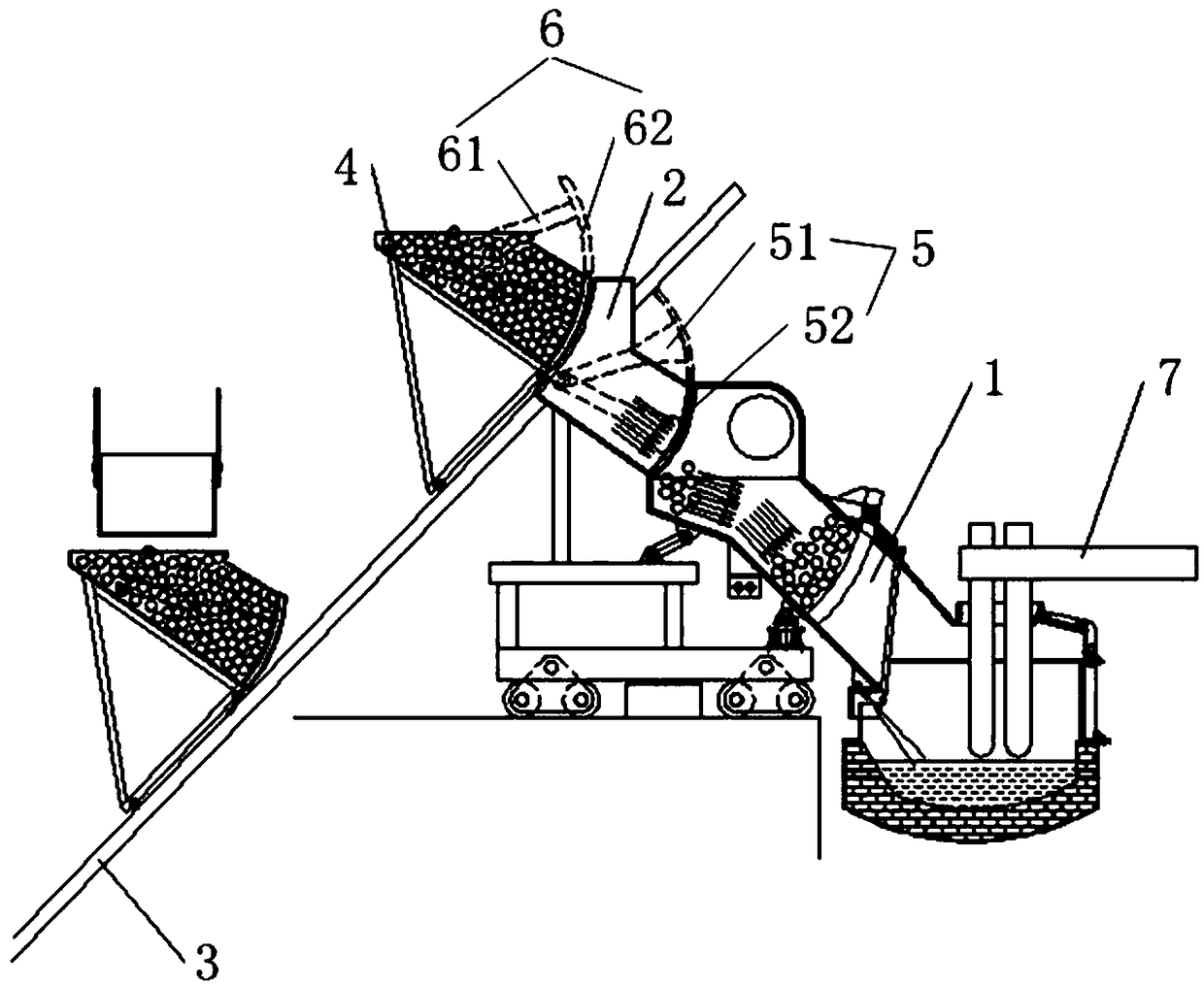

[0023] Such as figure 1 As shown, the electric arc furnace sealed inclined rail automatic feeding device in this embodiment includes a feeding inclined hopper 2 connected to the scrap steel preheating chamber 1 and a lifting inclined hopper 4 that automatically performs reciprocating lifting movement on the inclined rail 3. The feeding inclined hopper 2 and the bottom of the lifting inclined hopper 4 are correspondingly provided with a material-retaining sealing door I5 and a material-retaining sealing door II6, and the material-retaining sealing door II6 is a material-retaining sealing door II. When the lifting inclined hopper 4 is connected with the feeding inclined hopper 2, the material blocking airtight door II 6 blocks the feeding inclined hopper 2 to form an airtight compartment.

[0024] The feeding device utilizes the inclined rail 3 and the closed compartment to realize fully sealed automatic scrap steel feeding. Specifically, the lifting inclined hopper 4 on the in...

Embodiment 2

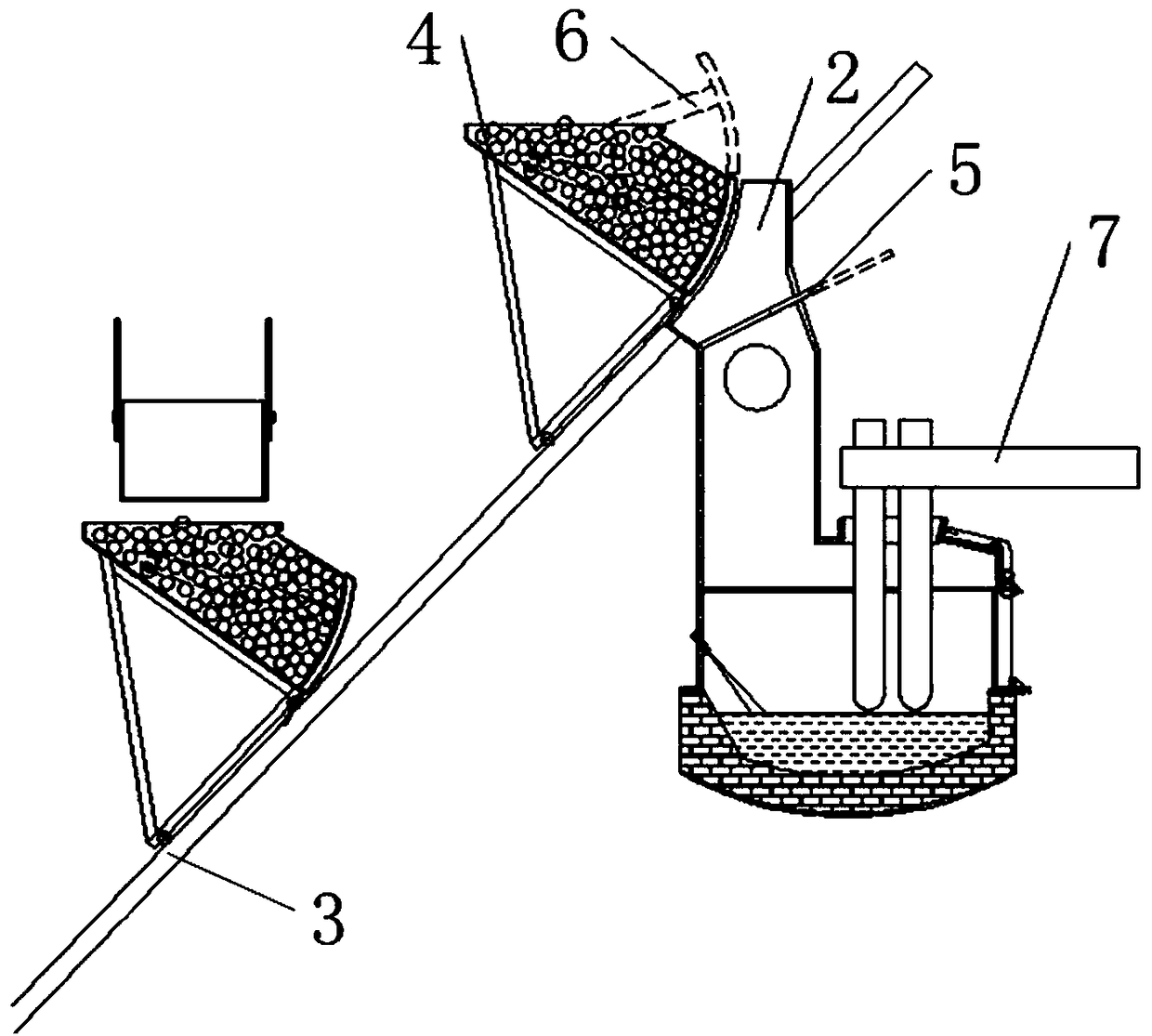

[0031] Such as figure 2 As shown, the electric arc furnace sealed inclined rail automatic feeding device in this embodiment includes a feeding inclined hopper 2 connected to the electric arc furnace body 7 and a lifting inclined hopper 4 that automatically performs reciprocating lifting motion on the inclined rail 3. The feeding The bottom ends of the inclined hopper 2 and the lifting inclined hopper 4 are correspondingly provided with a material-retaining sealing door I5 and a material-retaining sealing door II6, and the material-retaining sealing door II6 is a material-retaining sealing door II. When the lifting inclined hopper 4 is connected with the feeding inclined hopper 2, the material blocking airtight door II 6 blocks the feeding inclined hopper 2 to form an airtight compartment.

[0032] The feeding device utilizes the inclined rail 3 and the closed compartment to realize fully sealed automatic scrap steel feeding. Specifically, the lifting inclined hopper 4 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com