A piling system suitable for lifting platforms

A lifting platform and platform technology, which is applied in the field of lifting platforms, can solve the problems of wasting manpower, etc., and achieve the effect of saving labor and avoiding shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

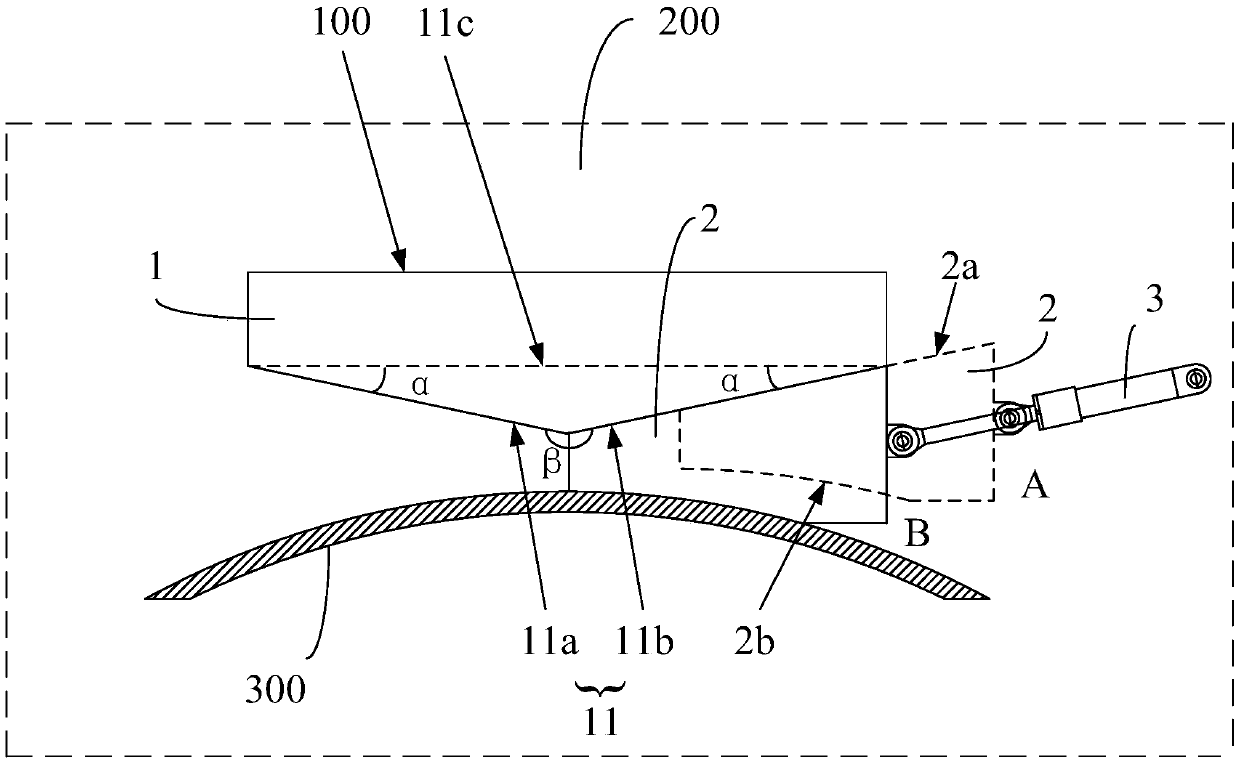

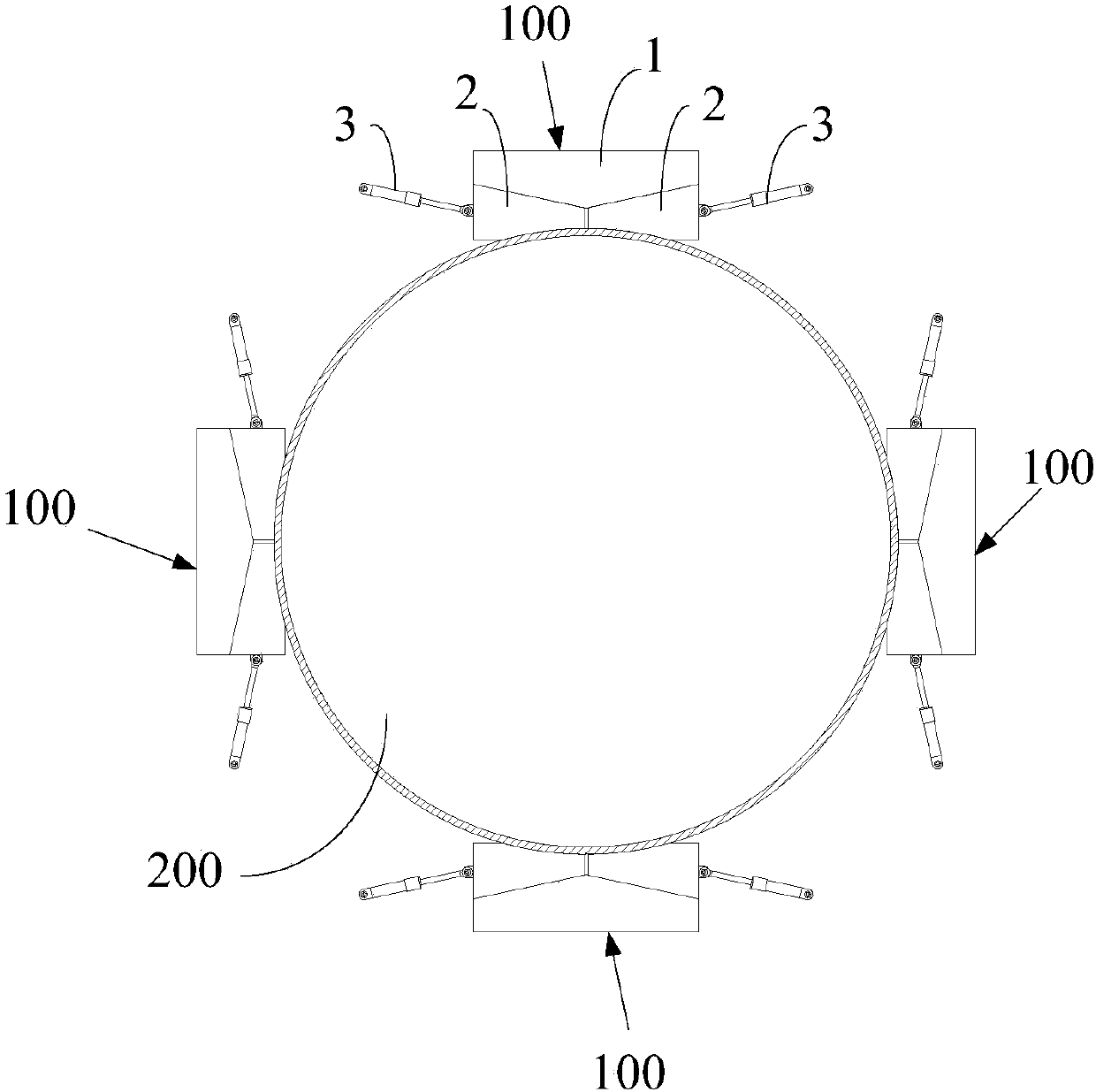

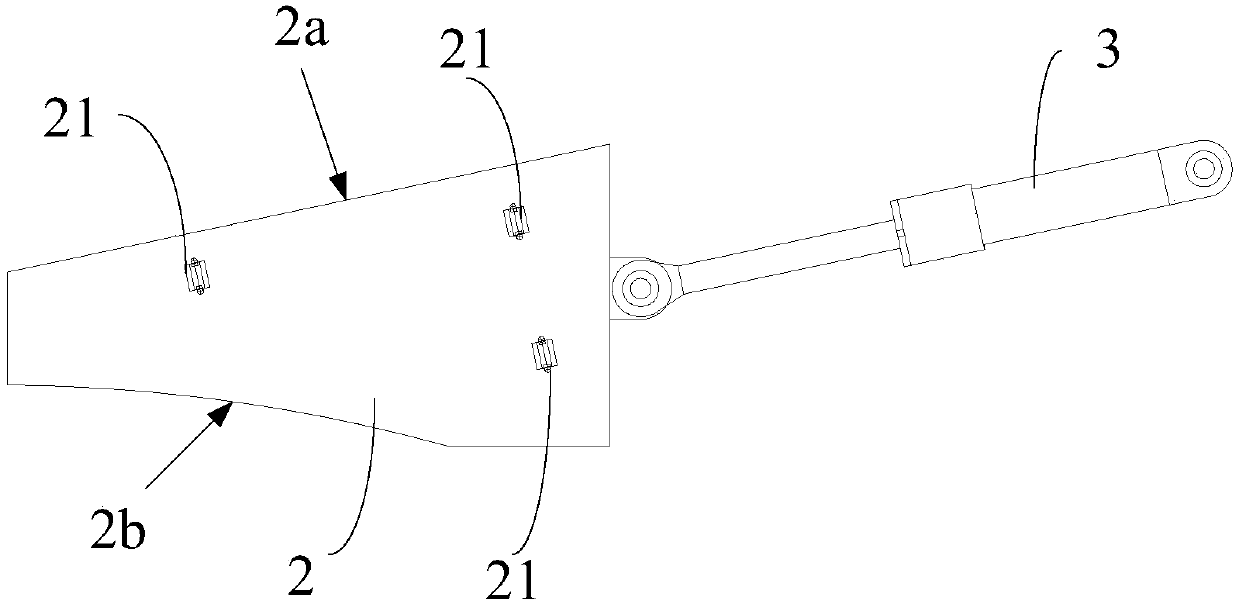

[0028] Embodiments of the present invention provide a pile fixing system suitable for lifting platforms, such as figure 1 As shown, the pile fixing system includes at least two pile fixing devices 100, and each pile fixing device 100 includes a positioning block 1, at least one pile fixing slider 2 and a telescopic oil cylinder 3 corresponding to the pile fixing slider 2 one by one. The block 1 is fixedly installed on the platform main body 200 of the lifting platform, the positioning block 1 is arranged at intervals with the legs 300 of the lifting platform, the positioning block 1 includes a slope 11 arranged toward the legs 300, and the pile fixing slider 2 is slidably arranged on the platform On the main body 200 and between the positioning block 1 and the leg 300, the pile fixing slider 2 has a matching surface 2a matching the slope 11 of the positioning block 1 and a friction surface 2b matching the outer peripheral wall of the leg 300. The surface 2a and the friction su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com