Clamping tool for inner plate of plastic tail door

A technology for clamping tooling and tailgate, applied in the field of tooling and fixtures, which can solve the problems of large rework workload, scrapped parts, and inability to guarantee batch size consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

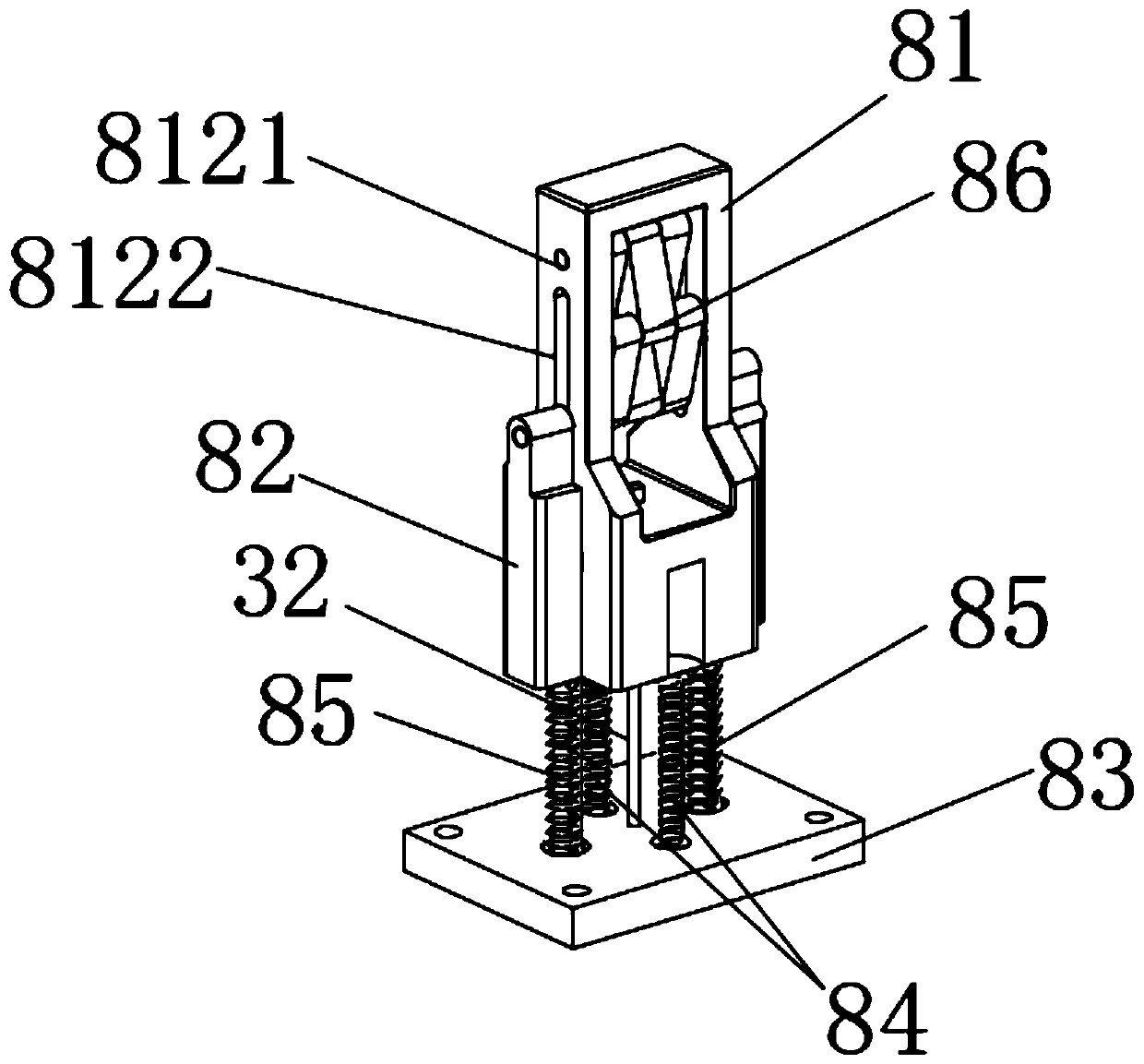

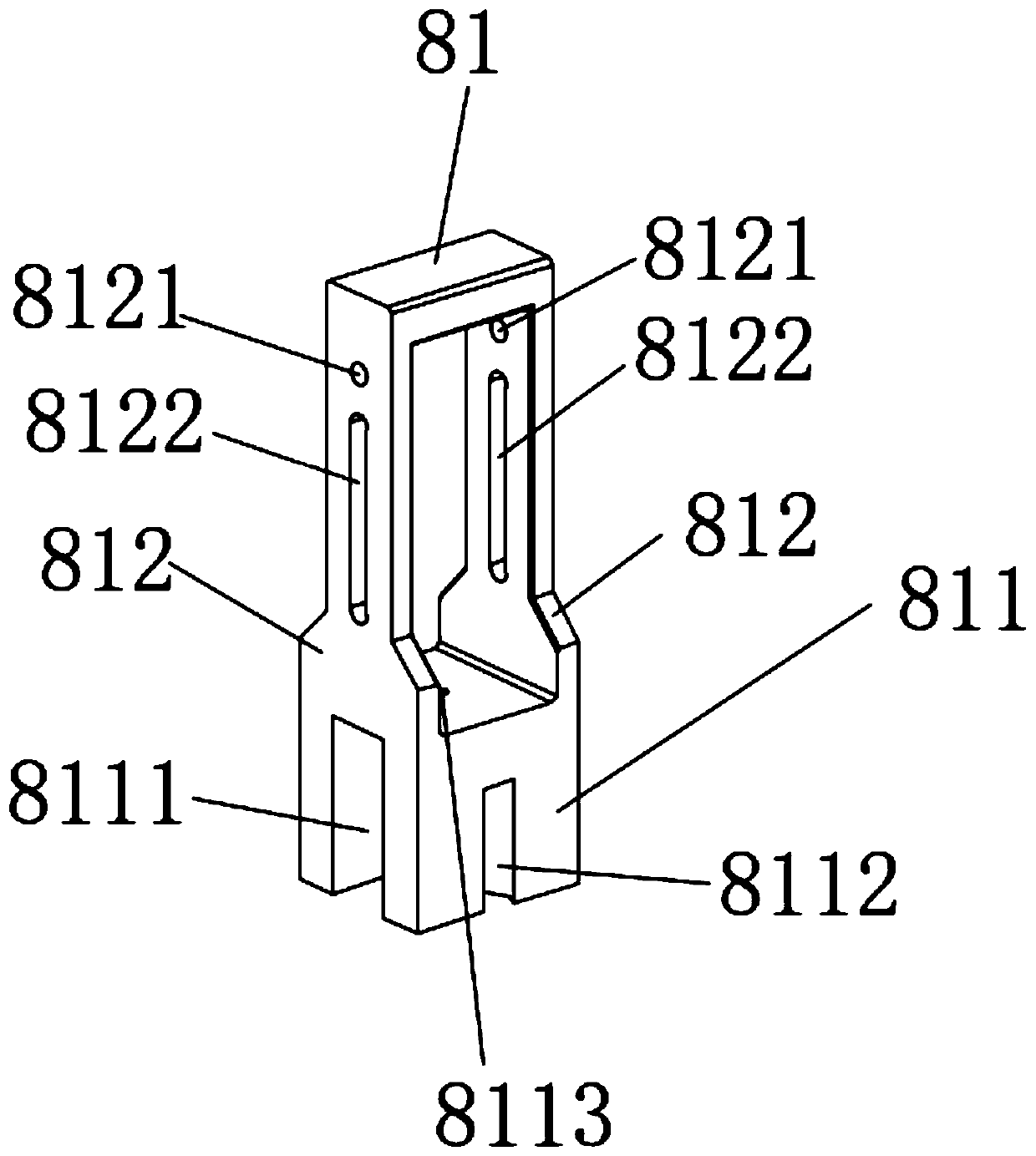

[0041] Such as Figure 1-Figure 4 As shown, the clamping tooling of the plastic tailgate inner panel disclosed by the present invention includes a clamping mechanism 8 and a pull cord 3, and the clamping mechanism 8 includes an upper fixing seat 81, a lower fixing seat 82, a bottom plate 83, a spring A84, and a spring B85 , four-bar linkage hinge 86 and limit block 4.

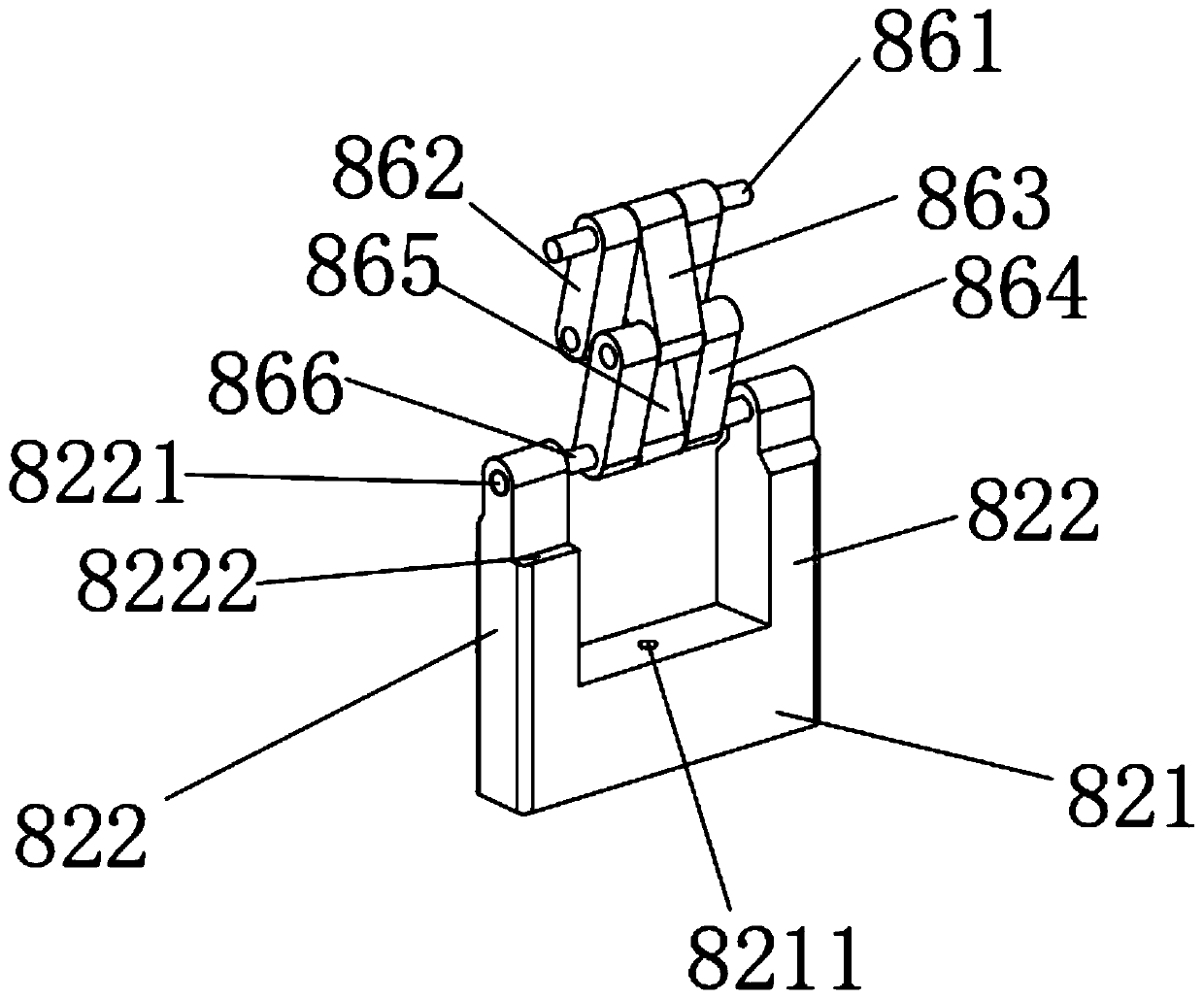

[0042] The four-link hinge 86 includes hinge lever A862, hinge lever B863, hinge lever C864, hinge lever D865, upper bearing pin 861 and lower bearing pin 866, and the upper end of hinge lever A862 and the upper end of hinge lever B863 are hinged by upper bearing pin 861, The lower end of the hinge rod B863 is hinged with the upper end of the hinge rod C864, the lower end of the hinge rod C864 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com