A composite plugging device for horizontal subsea oil tree

A technology for a Christmas tree and plug, which is applied to the field of a horizontal subsea Christmas tree composite plug device, can solve the problems of large design size space, increased processing difficulty, unfavorable construction, etc., to optimize the design space and size, and reduce the hidden danger of safe operation. , the effect of convenient repair work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

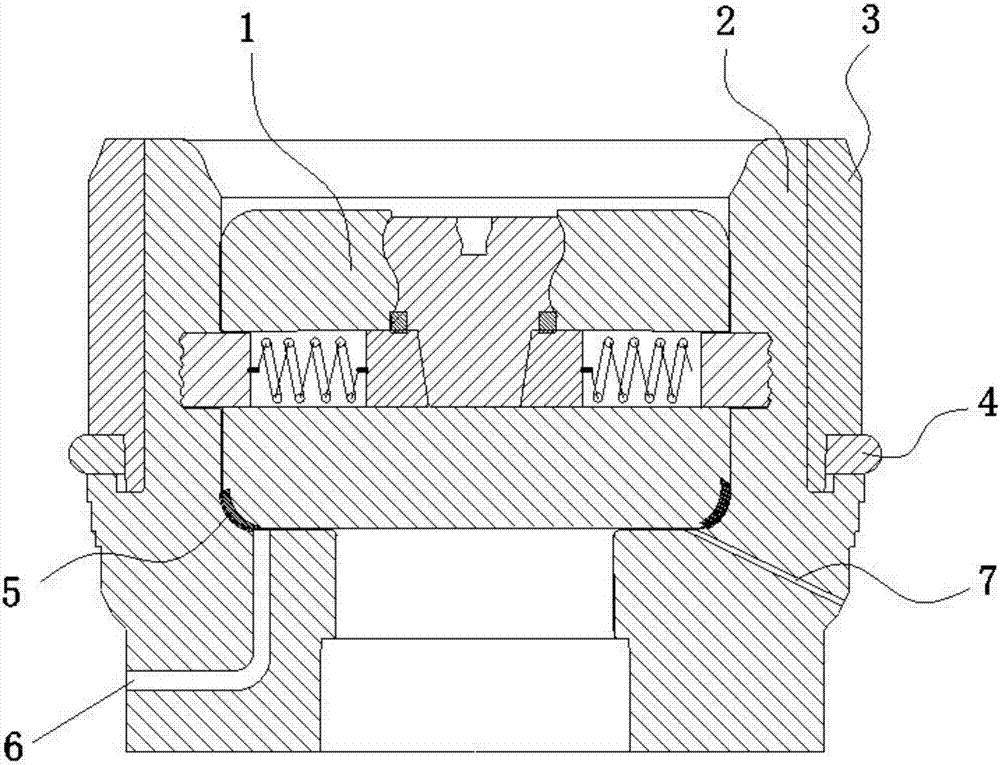

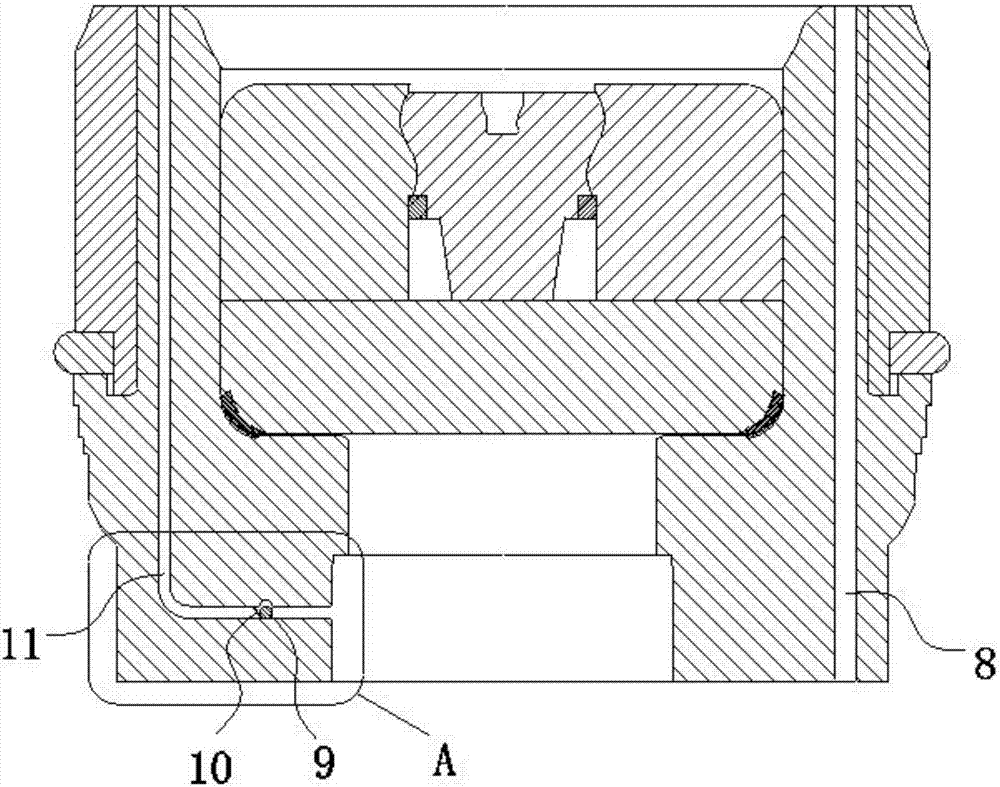

[0034] Such as Figure 1 to Figure 6 As shown, the steps of assembling the pressure bearing device 1 are as follows:

[0035] (1) Before cementing, conduct a ground sealing test through the composite plug test channel 5 to ensure the normal performance of the equipment and reduce the failure rate. After the test is completed, lower the tubing hanger 2 to the corresponding construction position with the drilling tool;

[0036] (2) Align the slot on the tubing hanger 2 with the transverse chute in the middle of the main body 107, apply a thrust to the limiting body 101 to move downward, and transmit the downward force to the movable slider through the tapered surface 102, making it generate an outward moving force, and then push the hanger lock block 105 to move outward through the spring 103, and snap into the slot of the tubing hanger 2, and the pressure bearing device 1 is installed;

[0037] (3) Use a tool to lower the sliding sleeve 3, push the elastic lock ring 4 to expan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com