Method for detecting and controlling position and attitude of two-column type hydraulic support

A hydraulic support and posture technology, applied in mine roof support, measuring device, earthwork drilling and other directions, can solve the problems of cumbersome control process, low precision, and reducing the stability of support work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

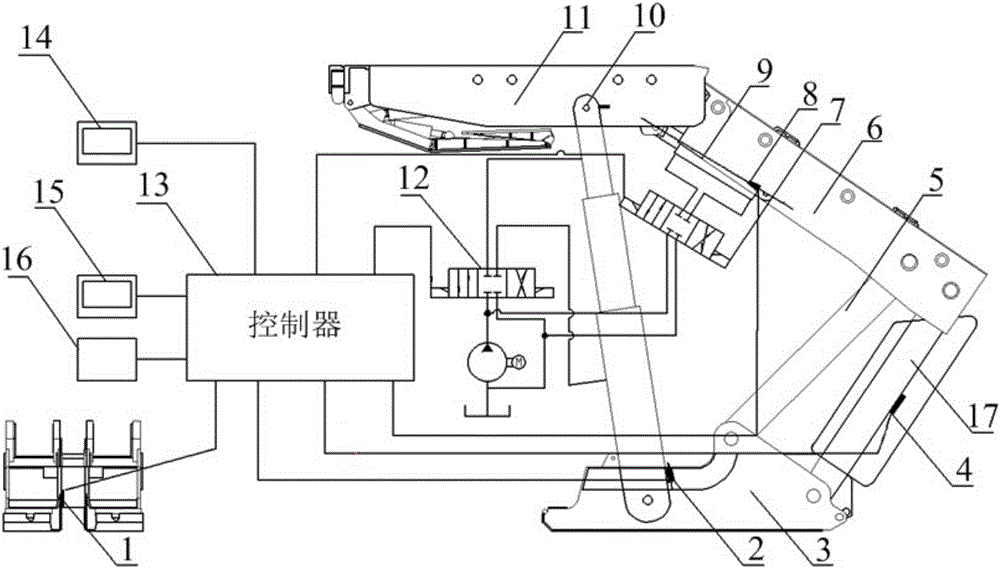

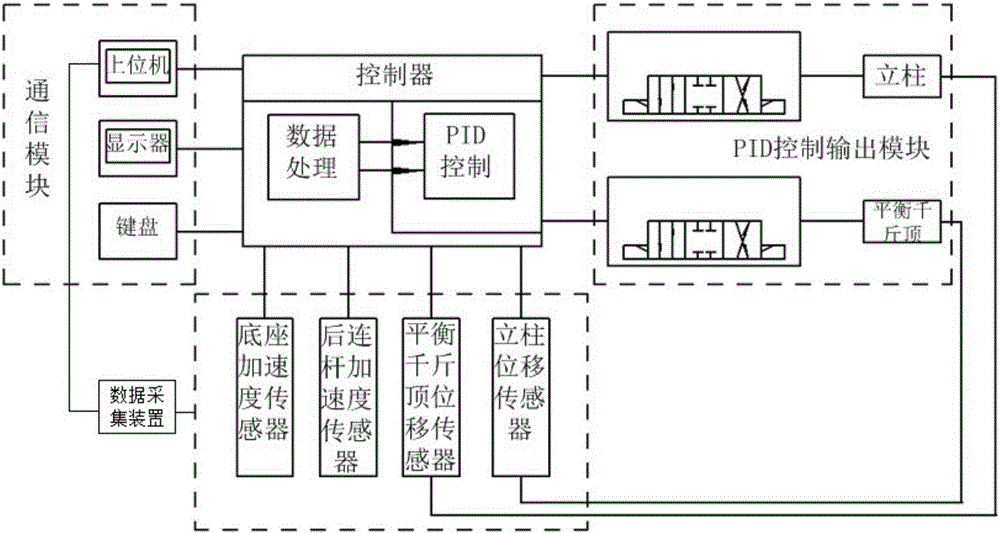

[0091] Such as figure 1 , figure 2 As shown, a method for detecting and controlling the position and attitude of a two-pillar hydraulic support includes a controller, a data acquisition device, a first acceleration sensor, a second acceleration sensor, a stroke sensor, a laser rangefinder, A detection and control system composed of a first electromagnetic proportional valve and a second electromagnetic proportional valve; wherein the first acceleration sensor is installed on the base of the hydraulic support, the second acceleration sensor is installed on the rear link of the hydraulic support, and the stroke sensor is installed on the hydraulic support The laser rangefinder is installed on the column of the hydraulic support. The first electromagnetic proportional valve is connected to the hydraulic control circuit of the hydraulic support balance jack. The second electromagnetic proportional valve is connected to the hydraulic control circuit of the hydraulic support column. ...

Embodiment 2

[0124] A method for the posture detection and control of a two-pillar hydraulic support. The method steps are as described in Example 1. The difference is that the input device in the inspection and control system uses a touch screen display / input module, and a touch screen display / input module Connected to the controller, the touch screen can omit the keyboard, and the operation is more convenient and intuitive.

[0125] Such as figure 2 As shown, the controller can also be connected to a host computer. The host computer needs to be connected to the first acceleration sensor, the second acceleration sensor, the stroke sensor and the laser rangefinder through an external data acquisition device for data collection. The host computer is a PC. , The data acquisition device is Advantech PCI-1711U data acquisition card, the host computer is connected with Advantech PCI-1711U data acquisition card, Advantech PCI-1711U data acquisition card is connected with the first acceleration sens...

Embodiment 3

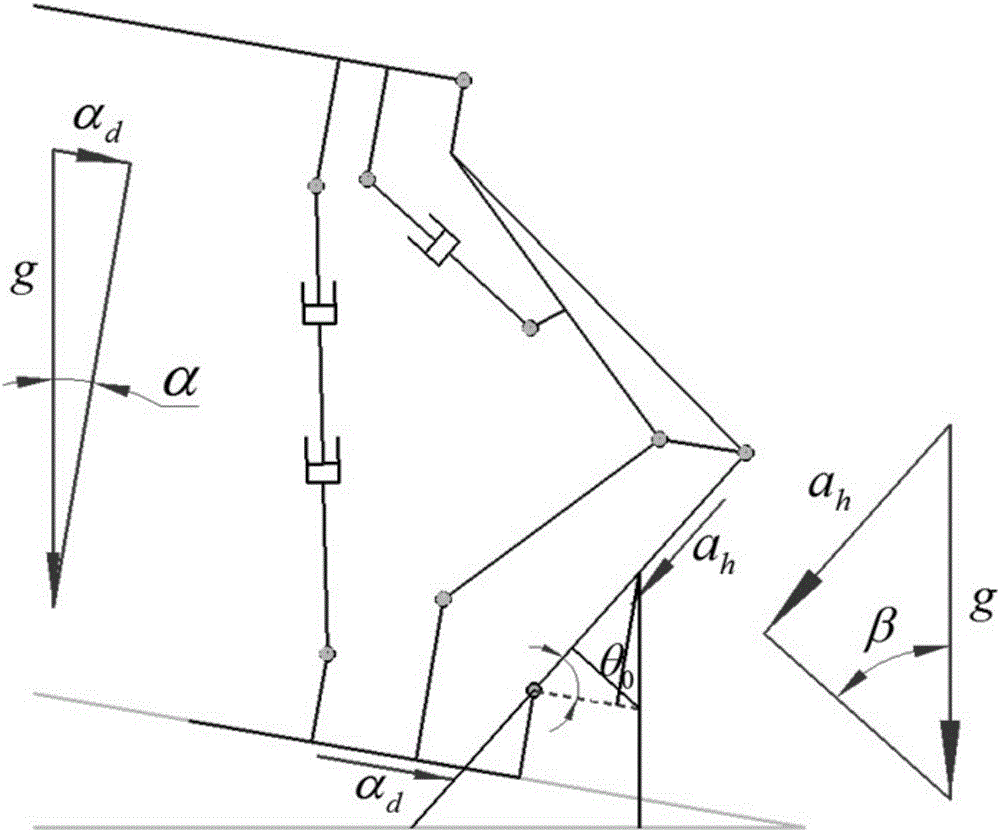

[0127] A method for the posture detection and control of a two-pillar hydraulic support. The method steps are as described in Example 1. The difference is that the method of using the system also includes inputting preset parameters and processing preset parameters In the process, before the hydraulic support goes into the well, the initial parameters of the hydraulic support are set through the keyboard and the display (the connecting rod and the base are hinged as the reference point), including the length of the rear connecting rod of the hydraulic support l 1 And positioning size height h 1 , The length of the front connecting rod of the hydraulic support l 3 And positioning size height h 2 , The distance between the base and the connecting rod hinge point l 2 The angle between its connecting line and the base θ 2 ,The positioning dimension of the lower column socket h 3 And l 9 And upper column socket positioning size h 6 And l 8 , The distance between the shield beam and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com