A two-column hydraulic support position and attitude detection and control system and its application

A technology of hydraulic support and control system, applied in mine roof support, mining equipment, earthwork drilling, etc., can solve the problems of cumbersome control process, low precision, and reducing the stability of support support.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

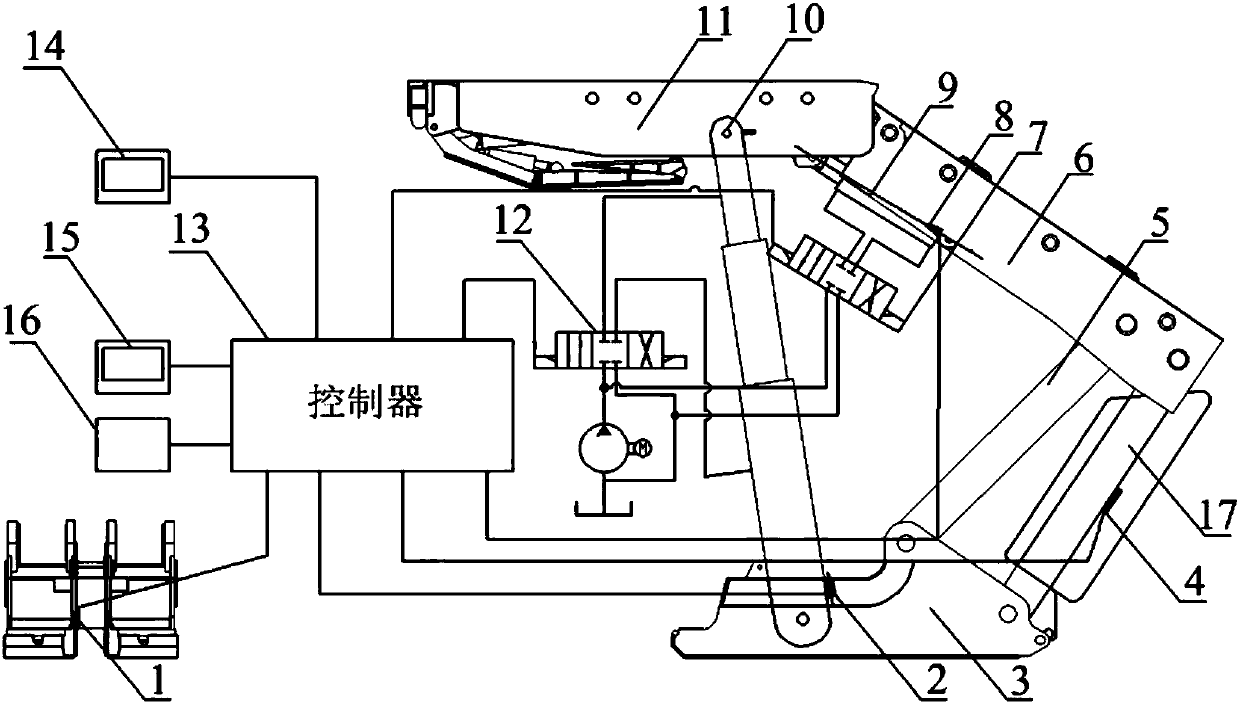

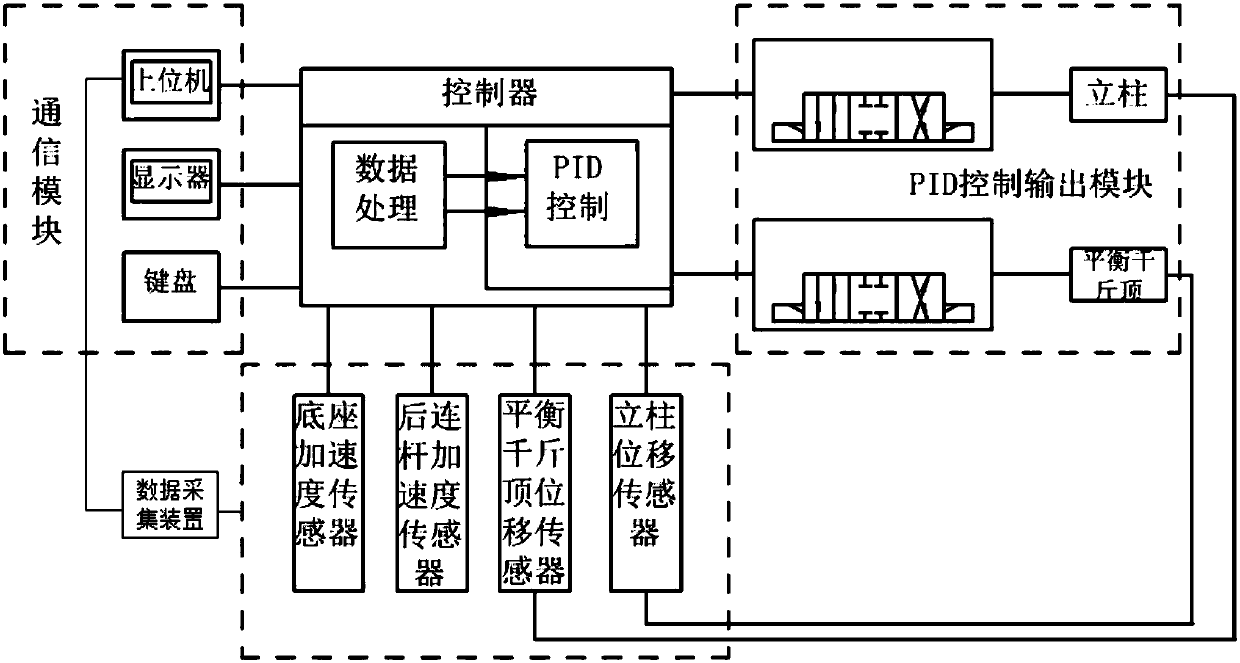

[0094] Such as figure 1 , figure 2As shown, a two-column hydraulic support posture detection and control system includes a controller, a data acquisition device, a first acceleration sensor, a second acceleration sensor, a travel sensor, a laser rangefinder, a first electromagnetic proportional valve and a second Two electromagnetic proportional valves; wherein, the first acceleration sensor is installed on the base of the hydraulic support, the second acceleration sensor is installed on the rear connecting rod of the hydraulic support, the stroke sensor is installed inside the balance jack of the hydraulic support, and the laser range finder is installed on the On the column of the hydraulic support, the first electromagnetic proportional valve is connected to the hydraulic control circuit of the hydraulic support balance jack, the second electromagnetic proportional valve is connected to the hydraulic control circuit of the hydraulic support column, the first acceleration s...

Embodiment 2

[0099] A two-column hydraulic support position and posture detection and control system, the components and their connections are as described in Embodiment 1, the difference is that: the input device uses a touch screen display / input module, and the touch screen display / input module and control The touch screen can omit the keyboard, and the operation is more convenient and intuitive.

[0100] The controller can also be connected with an external host computer. The host computer needs to be connected with the first acceleration sensor, the second acceleration sensor, the stroke sensor and the laser rangefinder through an external data acquisition device for data acquisition. The upper computer is a PC. Data acquisition The device is the Advantech PCI-1711U data acquisition card, the upper computer is connected with the Advantech PCI-1711U data acquisition card, the Advantech PCI-1711U data acquisition card is connected with the first acceleration sensor, the second acceleratio...

Embodiment 3

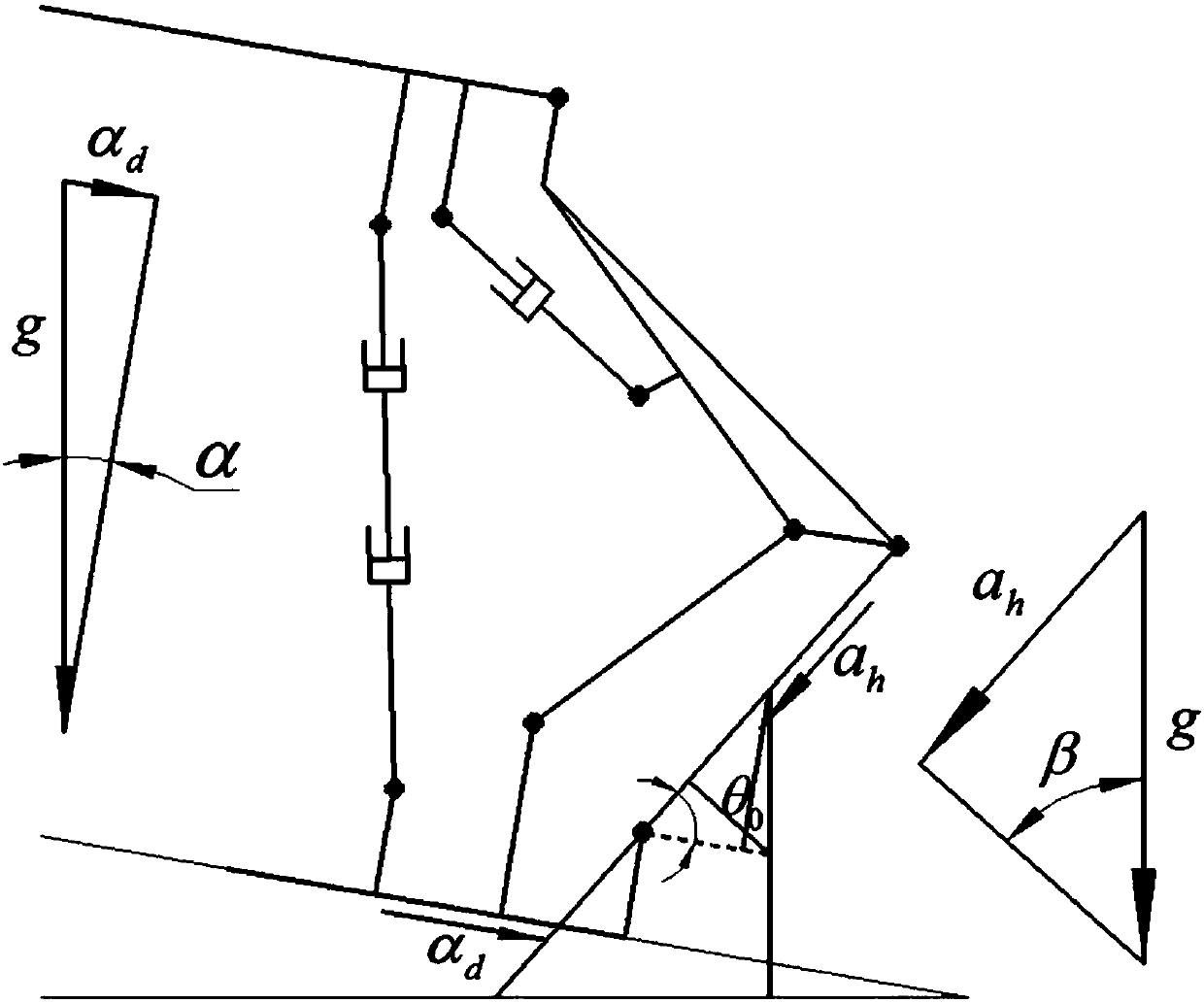

[0102] Such as Figure 3 to Figure 6 As shown, this embodiment provides a method for using the two-column hydraulic support pose detection and control system as described in Embodiment 1, including the following steps,

[0103] (1) Signal collection: the base acceleration measured by the first acceleration sensor, the rear link acceleration measured by the second acceleration sensor, the length of the hydraulic support balance jack measured by the stroke sensor, and the length of the column measured by the laser rangefinder are transmitted To the data acquisition device, the data acquisition device filters the received signal to obtain the original data of acceleration and length, and transmits the original data of acceleration and length to the MSP430F5438a microcontroller;

[0104] The filtering process refers to that the data acquisition device continuously samples N data, and then sorts the collected N data with the principle of heap sequence method, finds the maximum and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com