Combined flow control method and structure for improving SERN for TBCC

A flow control and secondary flow technology, applied in the field of aero-engines, can solve problems such as increasing design costs, increasing engine weight, increasing radar reflection area, etc., and achieves the effects of improving pressure distribution, thrust performance, and thrust coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

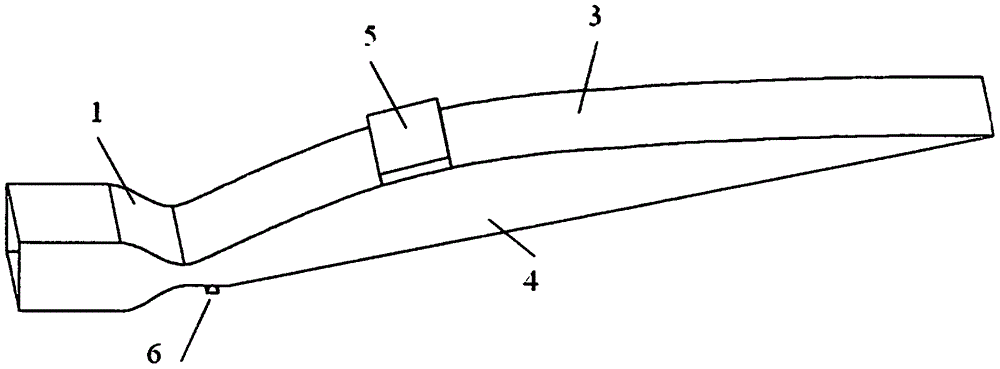

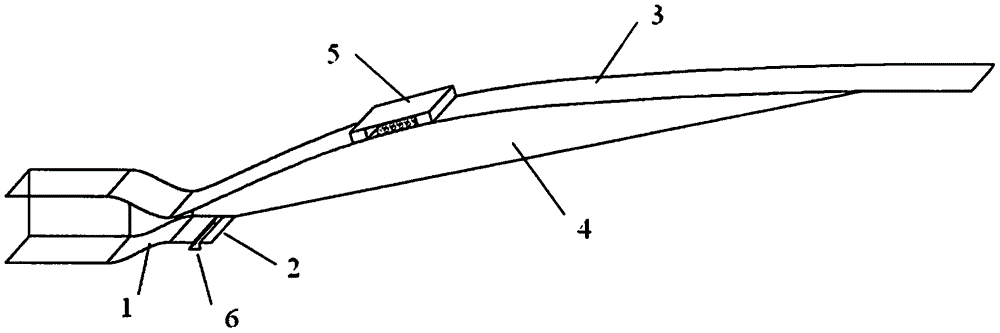

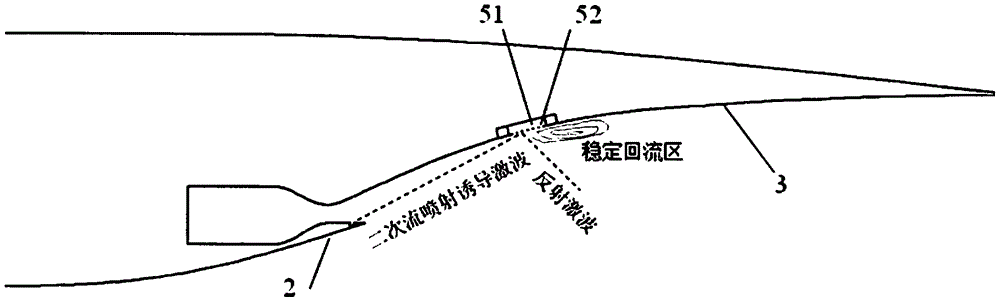

[0026] see Figure 1-7 As shown, in the present invention, a passive chamber structure is added to the upper expansion slope of the SERN, and a convergent secondary flow nozzle is opened on the lower slope of the SERN; under the premise of not significantly increasing the required control energy, a simple The passive cavity structure and the secondary flow injection device realize the control of the position of the oblique shock wave in the over-expansion state, thereby improving the pressure distribution of the nozzle on the single slope, increasing the thrust coefficient of the SERN in the over-expansion state, and improving the air-breathing high Thrust performance of a supersonic propulsion system in the transonic phase.

[0027] Please combine figure 1 As shown, the combined flow control structure o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com