Method for improving thrust coefficient of pulse detonation engine and spraying pipe

A thrust coefficient and engine technology, which is applied in the direction of machines/engines, jet propulsion devices, etc., can solve problems such as inconsistent conclusions, and achieve the effects of improving the thrust coefficient, uniform control, and convenient thrust control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

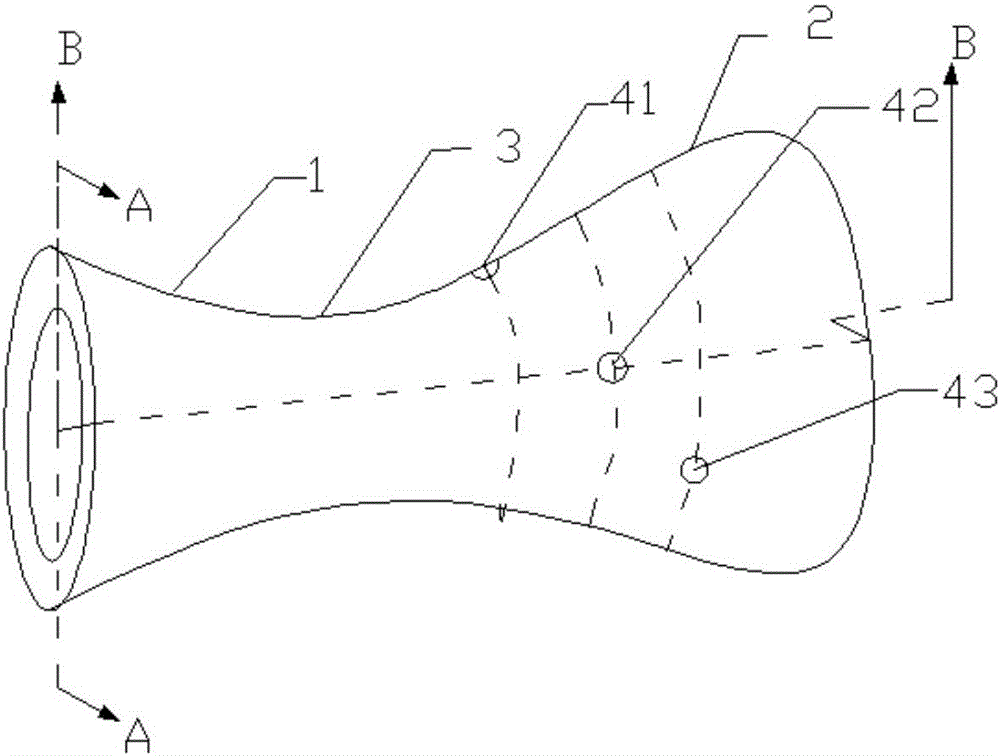

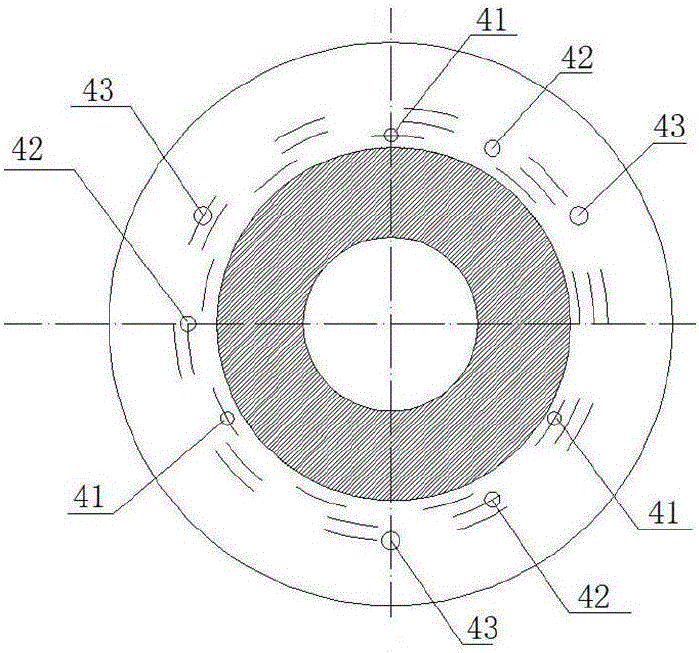

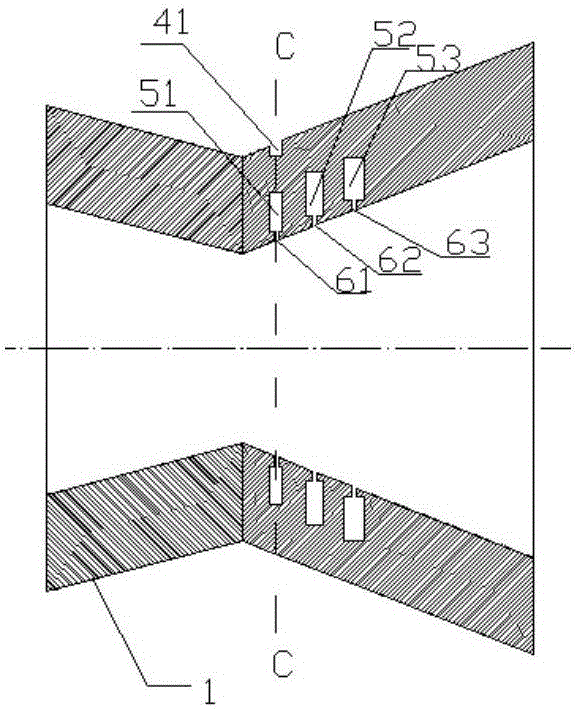

[0044] combine Figure 1-5 , three groups of annular jet flow holes are set in the pipe wall of the expansion section of the nozzle, and each group of jet flow holes is composed of an injection hole 4 , an annular channel 5 and an outflow annular hole 6 . Specifically, the first group of jet flow holes is composed of injection hole 41, annular channel 51 and outflow ring hole 61, the second group of jet flow holes is composed of injection hole 42, annular channel 52 and outflow ring hole 62, and the third group of jet flow holes is composed of injection hole 42, annular channel 52 and outflow ring hole 62. The group of jet flow holes is composed of injection holes 43, annular passages 53 and outflow annular holes 63. The annular passage 5 is an annular inner cavity in the pipe wall of the expansion section. A cylindrical hole communicating with the outside of the pipe, and the outflow ring hole 6 is a cylindrical hole uniformly distributed along the circumference that communic...

Embodiment 2

[0050] combine Figure 6-8 , three sets of annular jet flow holes are set between the inner and outer walls of the expanded section of the nozzle, and each set of jet flow holes is composed of cylindrical through holes 7 uniformly distributed along the circumference of the nozzle. The axial distance between the first group of jet flow holes 71 and the nozzle throat is 0.006-0.008m, and the axial distance between the second group of jet flow holes 72 and the first group of jet flow holes 71 is 0.006-0.008m Similarly, the third group of jet passage holes 73 has an axial distance from the second group of jet passage holes 72 of 0.006-0.008m.

[0051] Cylindrical through-holes 7 are provided along the radial direction of the nozzle, the diameter of cylindrical through-holes 7 is preferably 0.001-0.002m, and the distance between adjacent cylindrical through-holes in each group of jet through-holes is 0.002-0.004m, but it is certainly not limited thereto The distance, as long as th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com