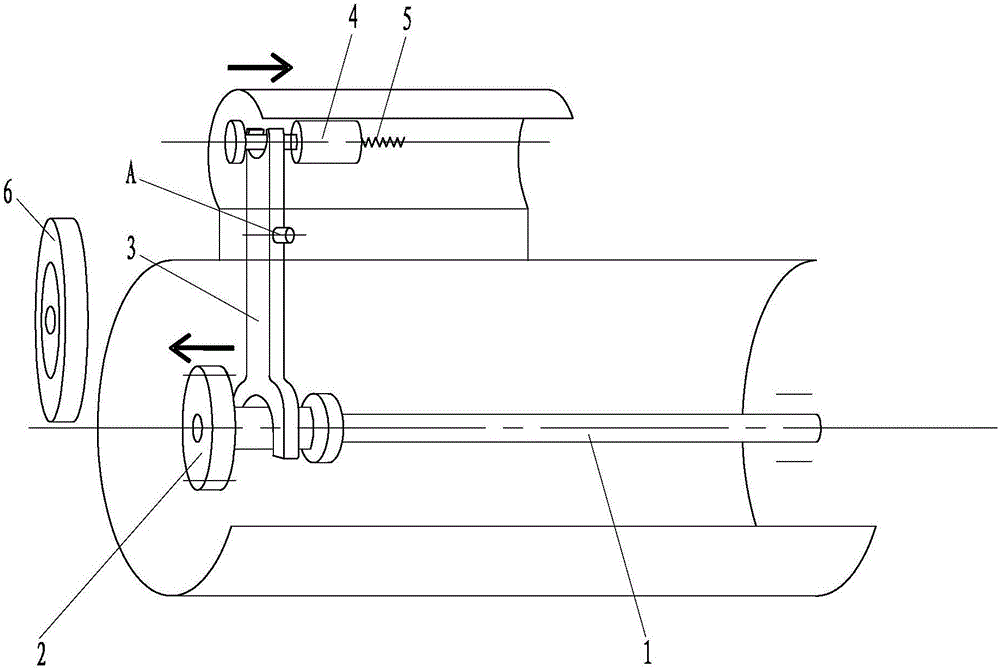

Electric motor starter with function of manual turning

A kind of starter and electric technology, applied in the direction of starting device with mechanical power storage, motor starting for engine, starting device with manual crank, etc., it can solve the problems of low efficiency, potential safety hazards, casualties and other problems, and achieve accurate The effect of positioning, improving efficiency, and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

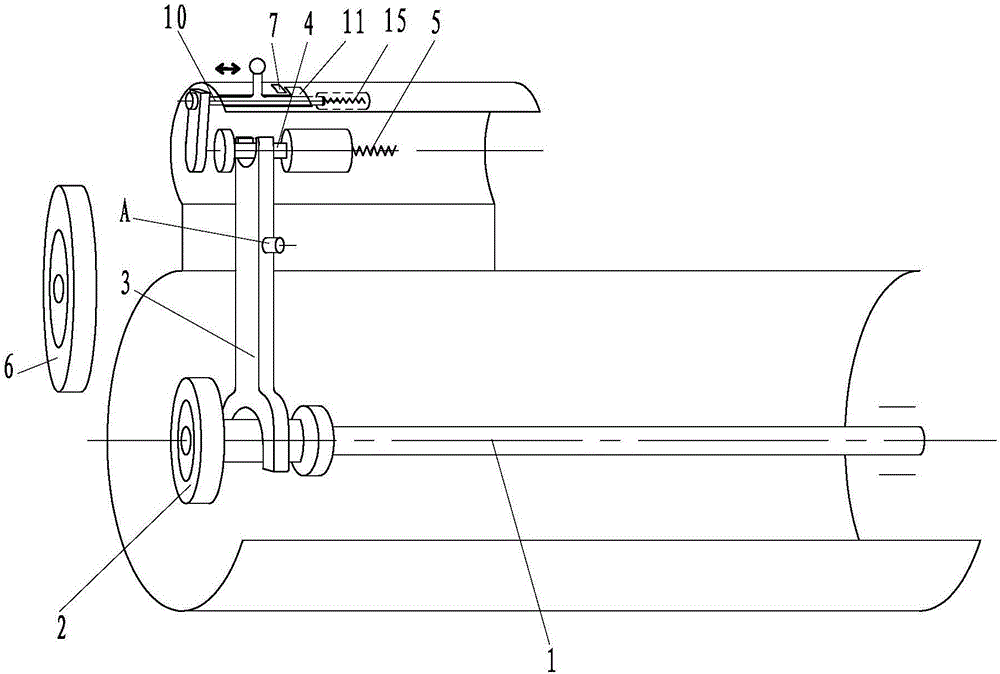

Embodiment 1

[0028] Such as figure 2 As shown, the shifting gear mechanism is composed of a push rod mechanism 10 , a normally closed switch 7 , a locking groove 11 and a second return spring 15 . The push rod mechanism 10 is used as a force-bearing member, the locking groove 11 is used as a positioning member, and the second return spring 15 is used as a first return member. The push rod mechanism 10 is located directly above the electromagnetic relay guide rod 4. The top of the push rod mechanism 10 has a toggle handle. The left end of the push rod mechanism 10 extends downward to form a push plate facing the electromagnetic relay guide rod 4, and the locking groove 3 on the electric starter housing, the second return spring 15 is installed on the right end of the push rod mechanism 10, and the electric starter housing is also provided with a chute for the toggle handle on the top of the push rod mechanism 10 to pass through.

[0029] The handle is moved by external force, and the push...

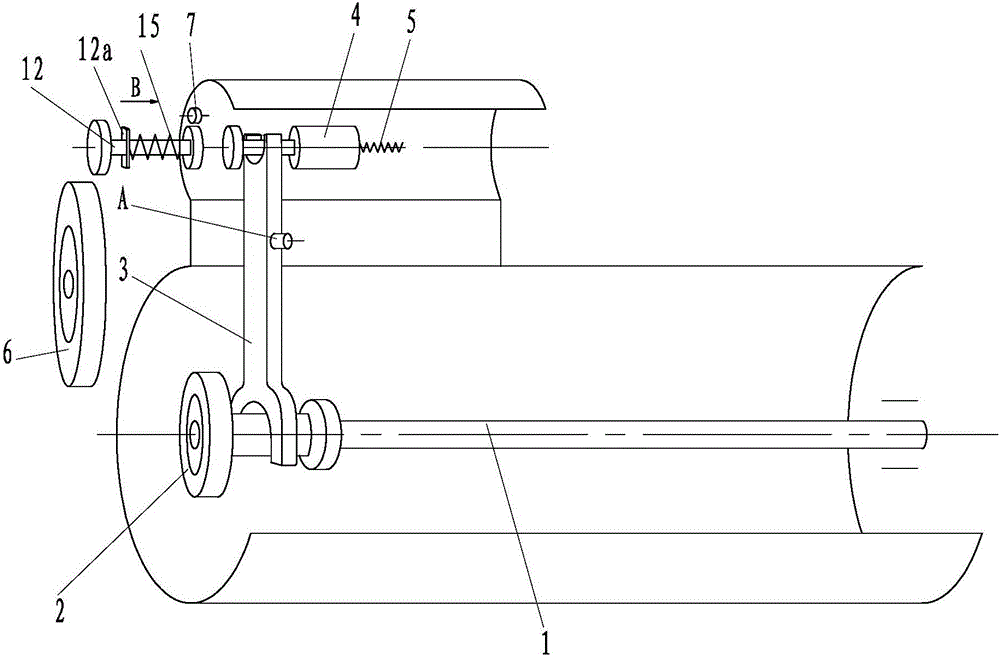

Embodiment 2

[0031] Such as image 3 , Figure 4 As shown, the gear shifting mechanism is composed of a push rod 12 , a normally closed switch 7 and a second return spring 15 . The push rod 12 is used as a force-bearing member. The locking clip 12a provided on the push rod 12 and the corresponding notch 16 on the electric starter housing form a positioning member, and the second return spring 15 serves as a first return member. The push rod 12 is located on the left side of the electromagnetic relay guide rod 4, the push rod 12 is provided with a locking clip 12a, the left end of the push rod 12 is provided with a pressing plate, the right end of the push rod 12 is provided with a push plate, and the electric starter shell is provided with a Facing the notch 16 of the locking clip 12a, the second return spring 15 is sleeved on the push rod 12 .

[0032]The external force presses the plate, and the push plate pushes the guide rod 4 of the electromagnetic relay to move to the right. When t...

Embodiment 3

[0034] Such as Figure 5 As shown, the shifting gear mechanism is composed of a clamping plate 14, a normally closed switch 7 and a shifting fork extension rod 13 formed by extending the top end of the shifting fork 3 upwards. The electric starter housing is provided with a chute for the toggle handle at the top of the shift fork extension rod 13 to pass through.

[0035] External force acts on the toggle handle at the top of the shift fork extension rod 13, and the toggle handle stretches out of the electric starter housing. The electromagnetic relay guide rod 4 is pushed to the right by the shift fork extension rod 13. When the shift fork extension rod 13 moves to the limit position, the shift fork extension rod 13 is locked after the clamp plate 14 is rotated, and the normally closed switch 7 cuts off the electric starter. The power supply makes the driving gear mechanism 2 mesh with the engine flywheel ring gear 6, and the shift fork extension rod 13 automatically returns...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com