Efficient running control method for water ring vacuum pump unit and control system

A water ring vacuum pump, high-efficiency operation technology, applied in the direction of pumps, mechanical equipment, machines/engines, etc., can solve the problems of water ring vacuum pump speed fluctuations, slow stabilization speed, and difficult pre-determined optimal water volume, etc., to achieve control stability Good, adaptable, power consumption reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below with reference to accompanying drawing, further say description:

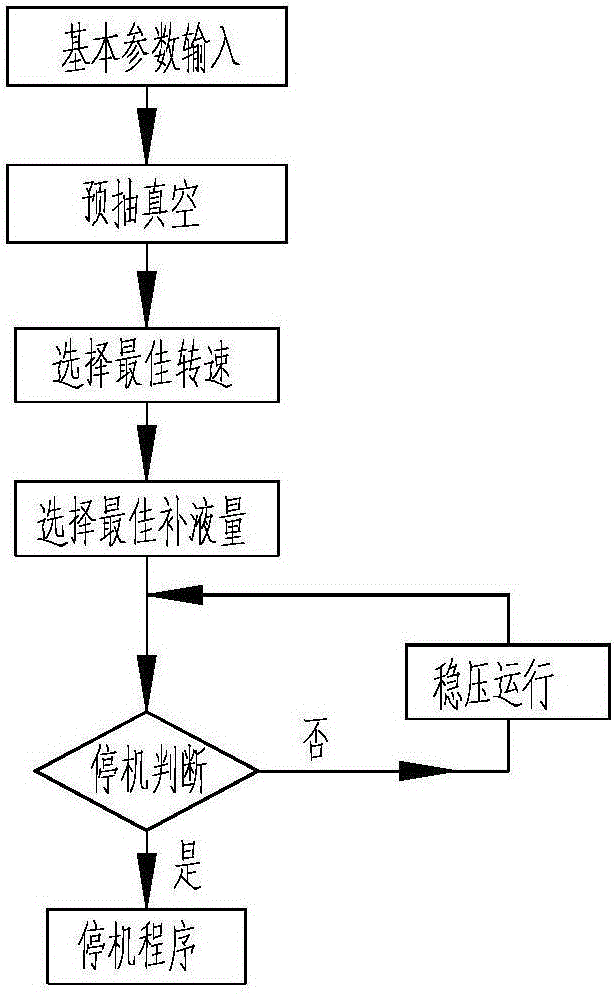

[0024] Such as figure 1 As shown, according to this patent, a method for controlling the efficient operation of a water ring vacuum pump unit includes steps such as pre-vacuumizing, selecting the optimal rotating speed, selecting the optimal liquid replenishment volume, stabilizing the operation, and judging the shutdown.

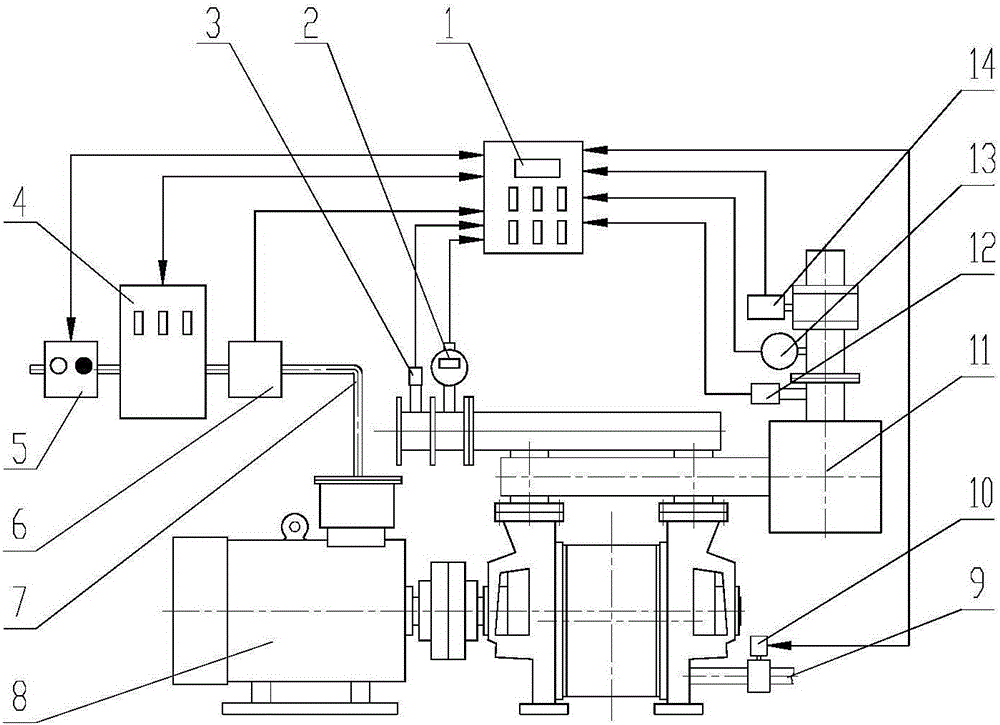

[0025] refer to figure 2 According to the present invention, a control system based on a high-efficiency operation control method for a water ring vacuum pump unit, wherein 1 is a control box, 2 is a suction pressure transmitter, 3 is a suction temperature transmitter, 4 is a frequency converter, and 5 is Switch, 6 is the power transmitter, 7 is the main cable, 8 is the water ring vacuum pump unit, 9 is the liquid inlet pipeline, 10 is the supplementary working fluid regulating valve, 11 is the gas-liquid separator, 12 is the exhaust temperature transmitter Device, 13 is an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com