Intelligent chip-drive compensation type industrial water supply pipeline pressurization system

A technology for water supply pipelines and pressurization systems, which is applied in pipeline systems, machines/engines, and liquid variable-capacity machinery, etc. Normal production, improve the use effect and scope of application, shorten the time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

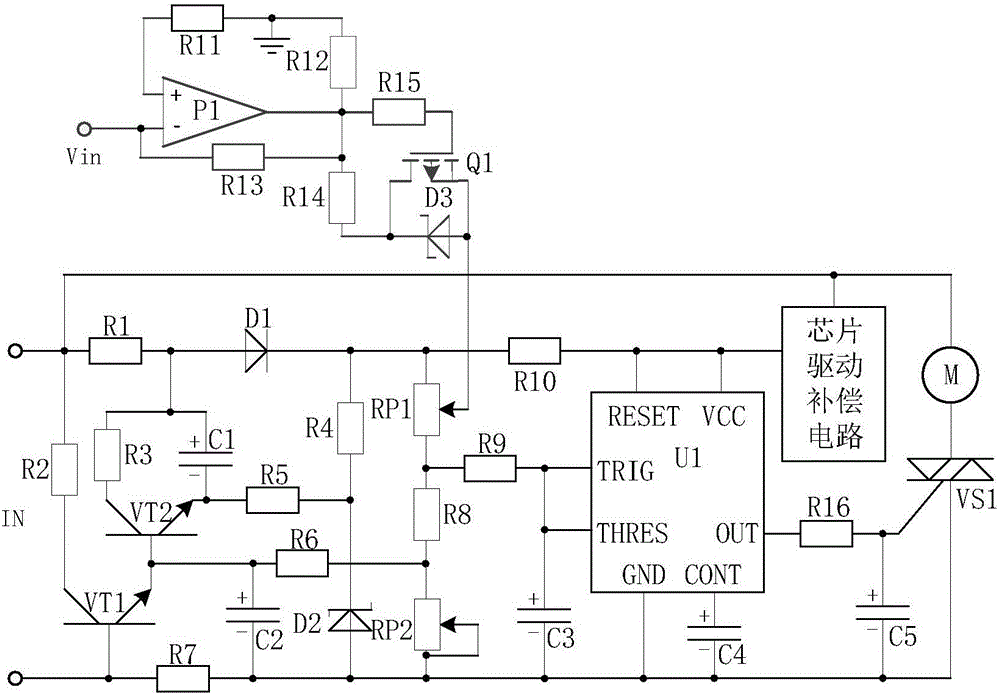

[0017] like figure 1 As shown, the chip-driven compensated industrial water supply pipeline intelligent booster system includes the control chip U1, the positive electrode is connected to the THRES pin and the TRIG pin of the control chip U1 at the same time, and the negative electrode is connected to the GND pin of the control chip U1. C3, the positive electrode is connected to the CONT pin of the control chip U1, and the negative electrode is connected to the GND pin of the control chip U1. Capacitor C4, the booster pump drive circuit connected to the control chip U1, and the power supply connected to the control chip U1 The input circuit is a signal processing input circuit connected to the control chip U1 and the power input circuit at the same time, and a chip drive compensation circuit connected to the control chip U1 and the power input circuit at the same time; wherein, the model of the control chip U1 is NE555.

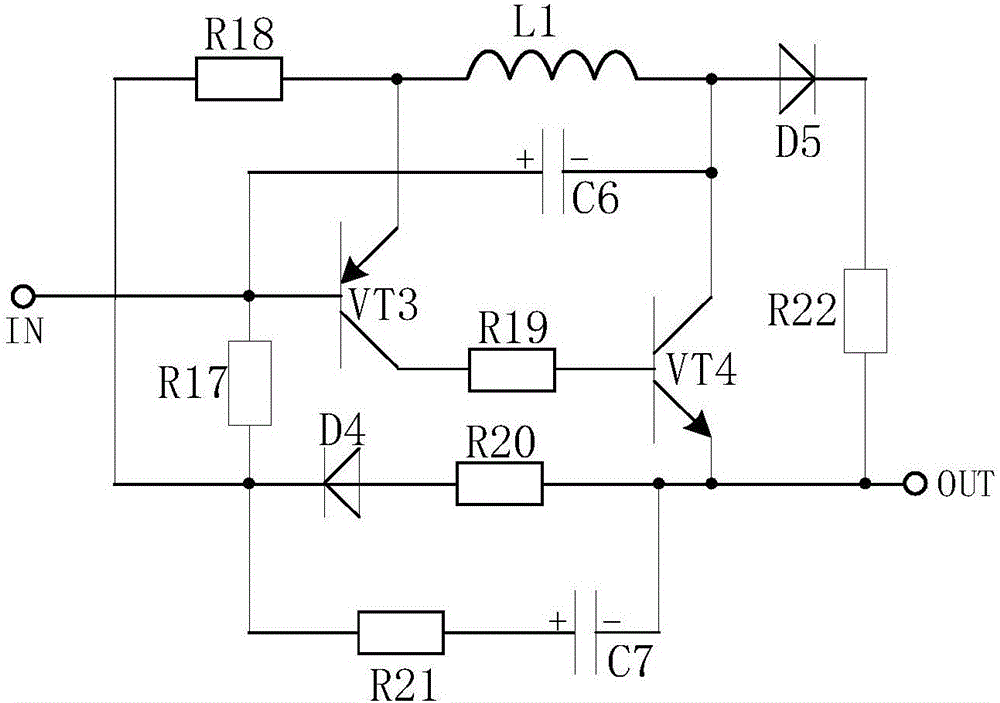

[0018] The power input circuit consists of transistor V...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com