Visual device for clearance control of air preheater

An air preheater and gap technology, applied in the field of visual devices, can solve problems such as whether the fan plate has been lifted in place and cannot be monitored, the air preheater motor overcurrent trips, and the environment is dusty, etc., to avoid inability to deal with it in time and reduce the number of lines The effect of connecting and solving complicated steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

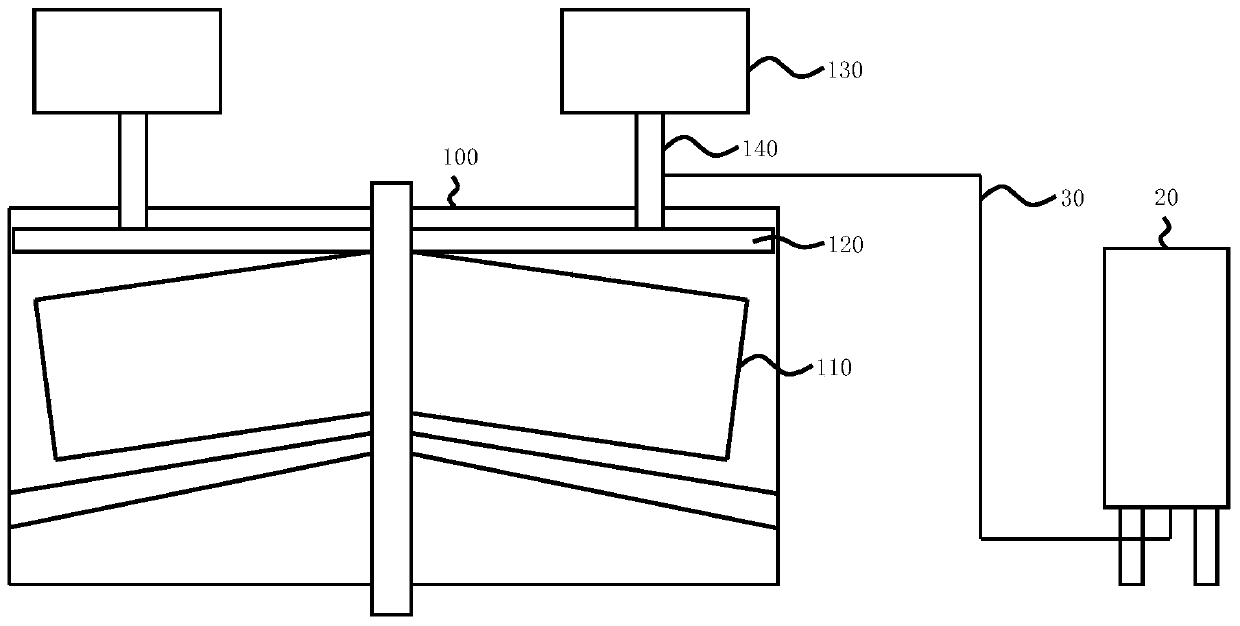

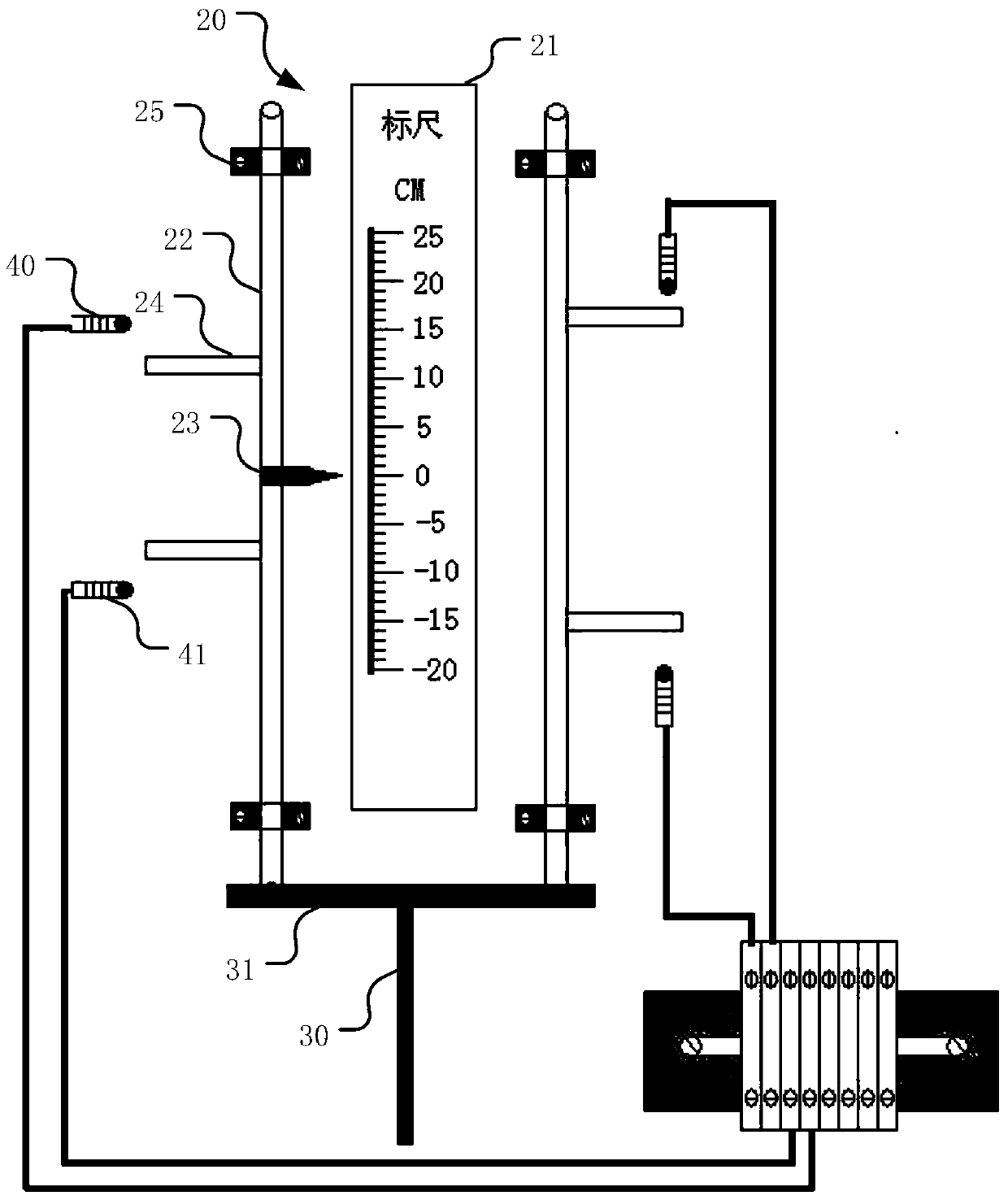

[0026] like Figure 1-3 As shown, the clearance control visual device of the embodiment of the present invention generally includes an upper fan-shaped plate 120 installed in the air preheater 100 to seal the upper end of the air preheater 100, and installed on the upper surface of the air preheater 100 according to The lifting device 130 for lifting the upper fan-shaped plate 120 in the air preheater 100 is instructed, and the monitoring device 20 is used for real-time response to the size of the gap between the upper fan-shaped plate 120 and the rotor 110 . The upper fan-shaped plate 120 may include a plurality of fan-shaped plates whose one end is connected with the rotating shaft of the rotor 110 and can be spliced into a circle; The lifting rod 140 connected to the fan-shaped plate 120; the monitoring device 20 may include an indicating device connected to the lifting device 130 and visually displaying the size of the gap between the upper fan-shaped plate 120 and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com