Simplified electric heating solid heat storage and thermal conversion device

A heat conversion and conversion device technology, which is applied in the field of electrothermal solid heat storage and heat conversion simplification devices, can solve the problem of high cost of hot water heating devices, save the cost of shutdown and heating, facilitate inspection and maintenance, and save input costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

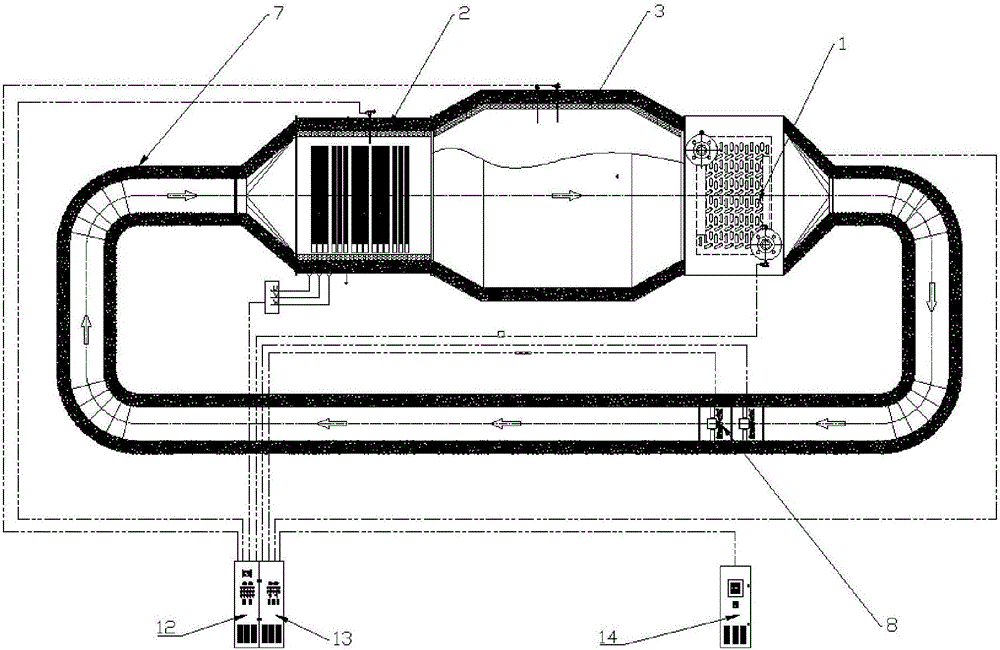

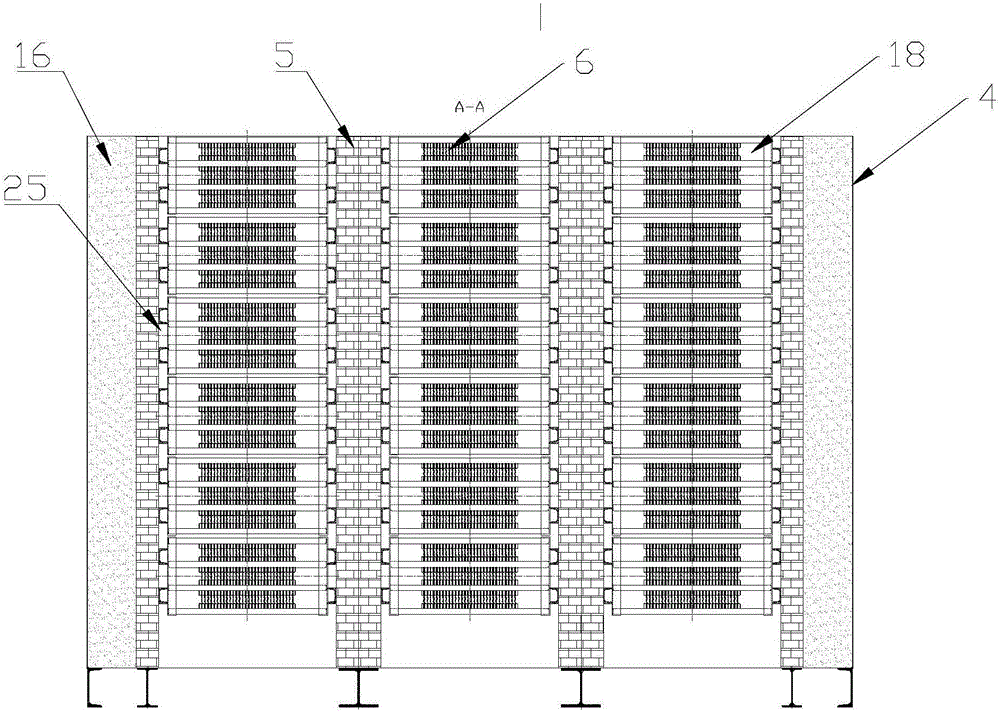

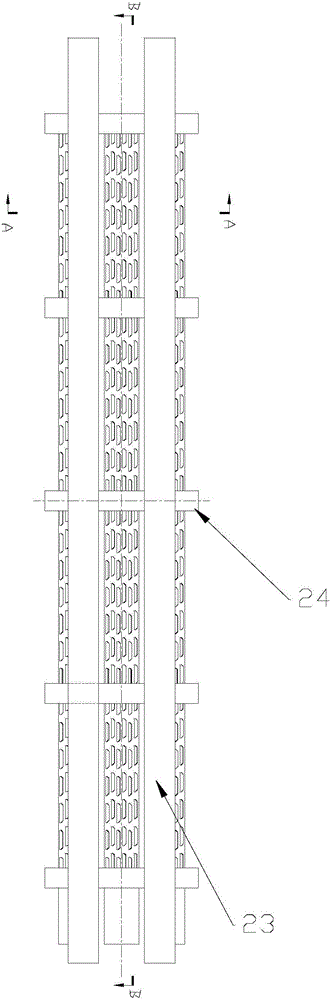

[0059] Such as Figure 1-8 As shown, an electrothermal solid heat storage and heat conversion facilitation device is provided in this embodiment, and the electrothermal solid heat storage and heat conversion facilitation device includes a high-voltage electric heat preservation furnace, a high-temperature circulating fan 8 and a heat exchange device 1; the high-voltage electric heat preservation heating furnace includes a heating furnace 2 and a heat preservation furnace 3; the heating furnace 2 includes a heating furnace body 4, and the heating furnace body 4 is provided with three passages 5 arranged side by side; Each of the passages 5 is provided with a plurality of electrothermal modules 6 placed side by side and insulated, and the plurality of electrothermal modules 6 are connected in series in sequence, and the plurality of electrothermal modules 6 are detachably connected to the channel 5 wall of the channel 5 ; A plurality of the electrothermal modules 6 in the three ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com