Gate valve body seat ring hole detecting device and application method

A technology of valve body seat and gate valve, which is applied in the field of gate valve body seat ring hole inspection tool, and can solve the problems such as inability to read values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

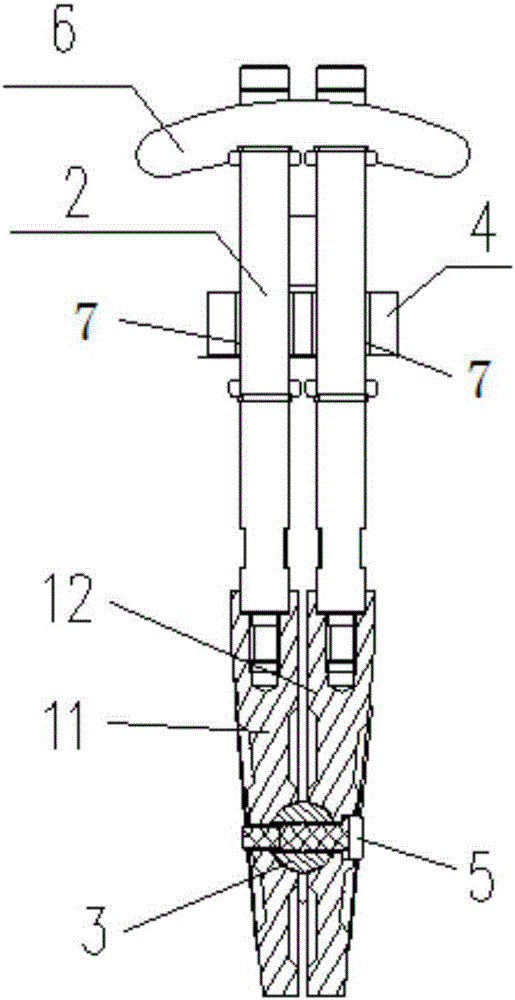

[0053] This embodiment provides a gate valve body seat ring hole inspection tool, which includes:

[0054] The oblique wedge 1, including a symmetrically arranged first oblique wedge 11 and a second oblique wedge 12;

[0055] Two measuring shafts 2, respectively connected to the top ends of the first oblique wedge 11 and the second oblique wedge 12, move synchronously with the first oblique wedge 11 and the second oblique wedge 12;

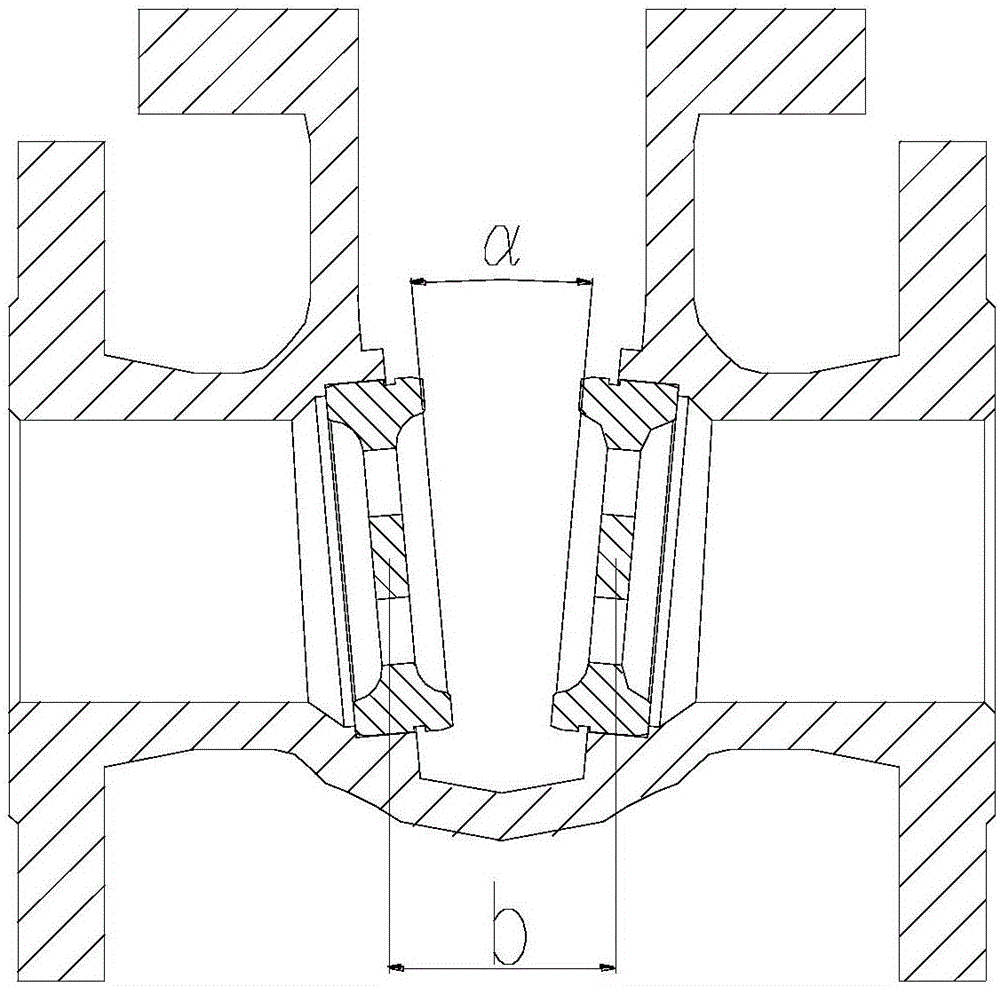

[0056] A steel ball 3 is provided between the first oblique wedge 11 and the second oblique wedge 12. Under the action of external force, the first oblique wedge 11 and the second oblique wedge 12 can use the steel ball 3 is the fulcrum rotation, which is pressed against the two seat rings adjacent to the first oblique wedge 11 and the second oblique wedge 12.

[0057] Such as image 3 As shown, the horizontal distance x between the two measuring shafts 2 is used to indicate the angle α between the two races. The larger the angle α between the races, the ...

Embodiment 2

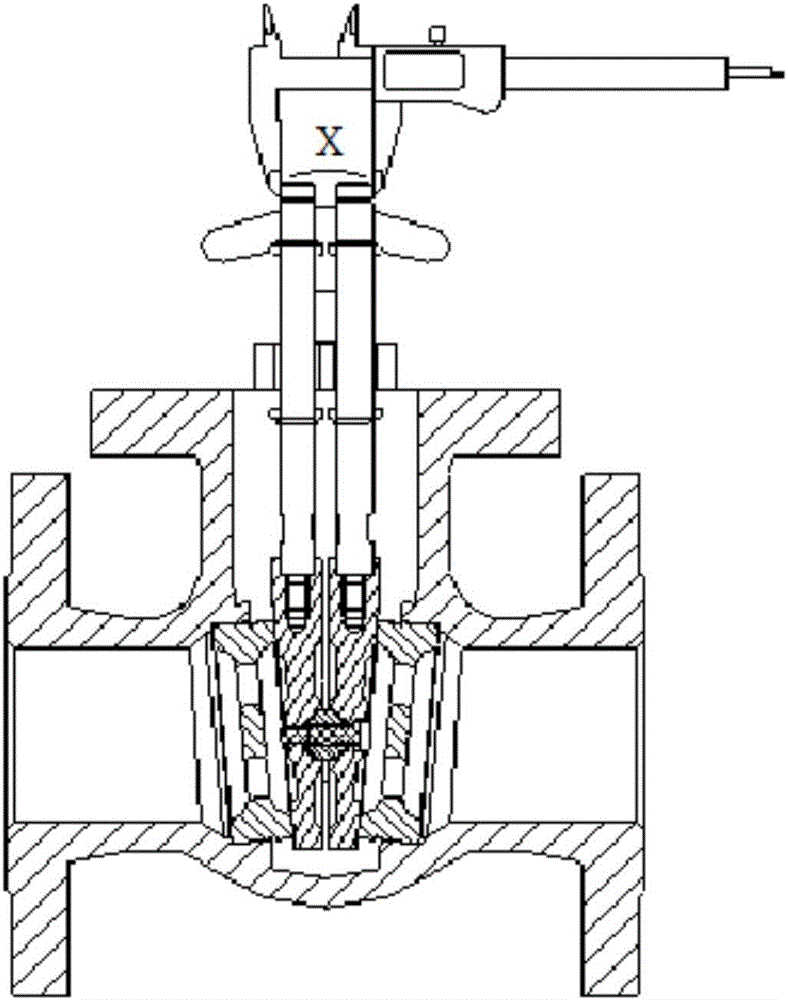

[0075] This embodiment provides a method for detecting a seat ring hole by the gate valve seat ring hole inspection tool, which includes the following steps:

[0076] Put the seat ring into the seat ring hole of the valve body along the inner cavity of the flange of the valve body;

[0077] Deepen the inspection tool along the flange end face of the valve body of the gate valve into the valve body;

[0078] The first oblique wedge 11 and the second oblique wedge 12 are tightly abutted on the two seat rings respectively, and the measuring plate 4 is abutted against the end surface of the middle flange in parallel;

[0079] Measure the horizontal distance x between the two measurement shafts 2 and / or measure the distance y between the top end of the measurement shaft 2 and the top end of the measurement board 4.

[0080] According to national standards or industry standards, the seat ring opening and the angle between the two sealing surfaces of the gate valve body have a certain theoreti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com