Quality measuring system for paralleling U-shaped tube

A quality measurement, U-shaped tube technology, applied in mass flow measurement devices, direct mass flow meters, measurement flow/mass flow, etc., can solve the problems of pipelines affecting the stability of flow signals, and achieve the effect of ensuring flow signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

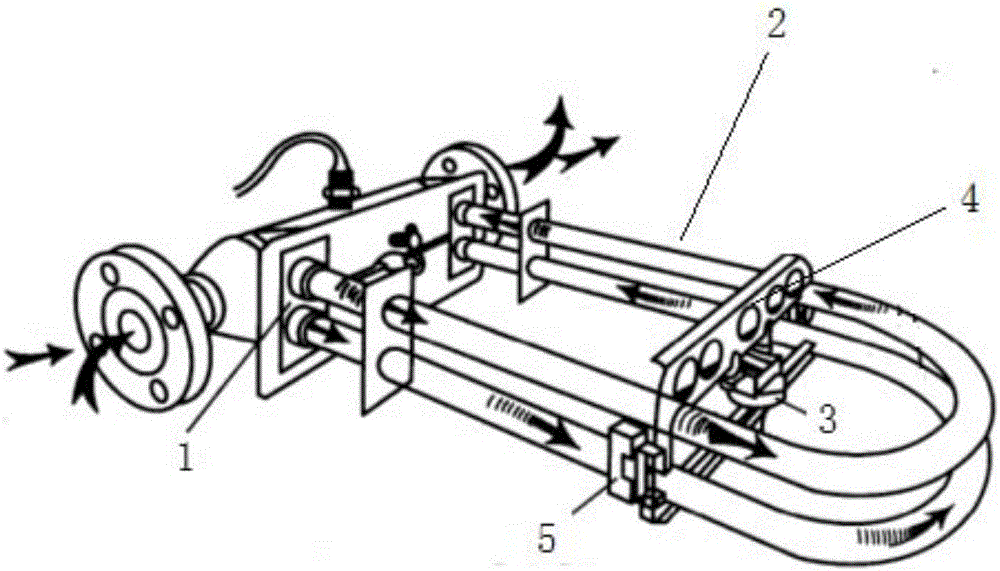

[0016] Example: Combine figure 1 : A parallel U-shaped tube quality measurement system, including parallel U-shaped tubes 2, flow distributor 1, electromagnetic vibrator 3, displacement signal sensor 5, the flow inflow end of parallel U-shaped tubes 2 and the inlet end of flow distributor 1 The flow outflow end of the parallel U-shaped tube 2 is connected with the outlet end of the flow distributor 1, the electromagnetic vibrator 3 is installed on the top of the parallel U-shaped tube 2, and there are two displacement signal sensors 5, two displacement signal sensors 5 They are respectively installed on both sides of the parallel U-shaped pipes 2.

[0017] Further, the displacement signal sensors 5 are respectively symmetrically installed at the tangent between the arc portion and the straight line portion at the top of the parallel U-shaped pipes 2 .

[0018] Further, a fixed bracket 4 is also included, and the fixed bracket 4 is installed between two displacement signal sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com