Floating monitoring system and monitoring method of formwork trolley in self-compacting concrete

A self-compacting concrete and formwork trolley technology, which is used in measuring devices, engine lubrication, liquid/fluid solid measurement, etc. It can solve the problem of uncertainty in test methods and positions, and the inability of eccentric force to react correctly and intuitively. The trolley floats degree, limitations and other problems, to achieve the effect of being beneficial to economy, ensuring the quality of molding and pouring, and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

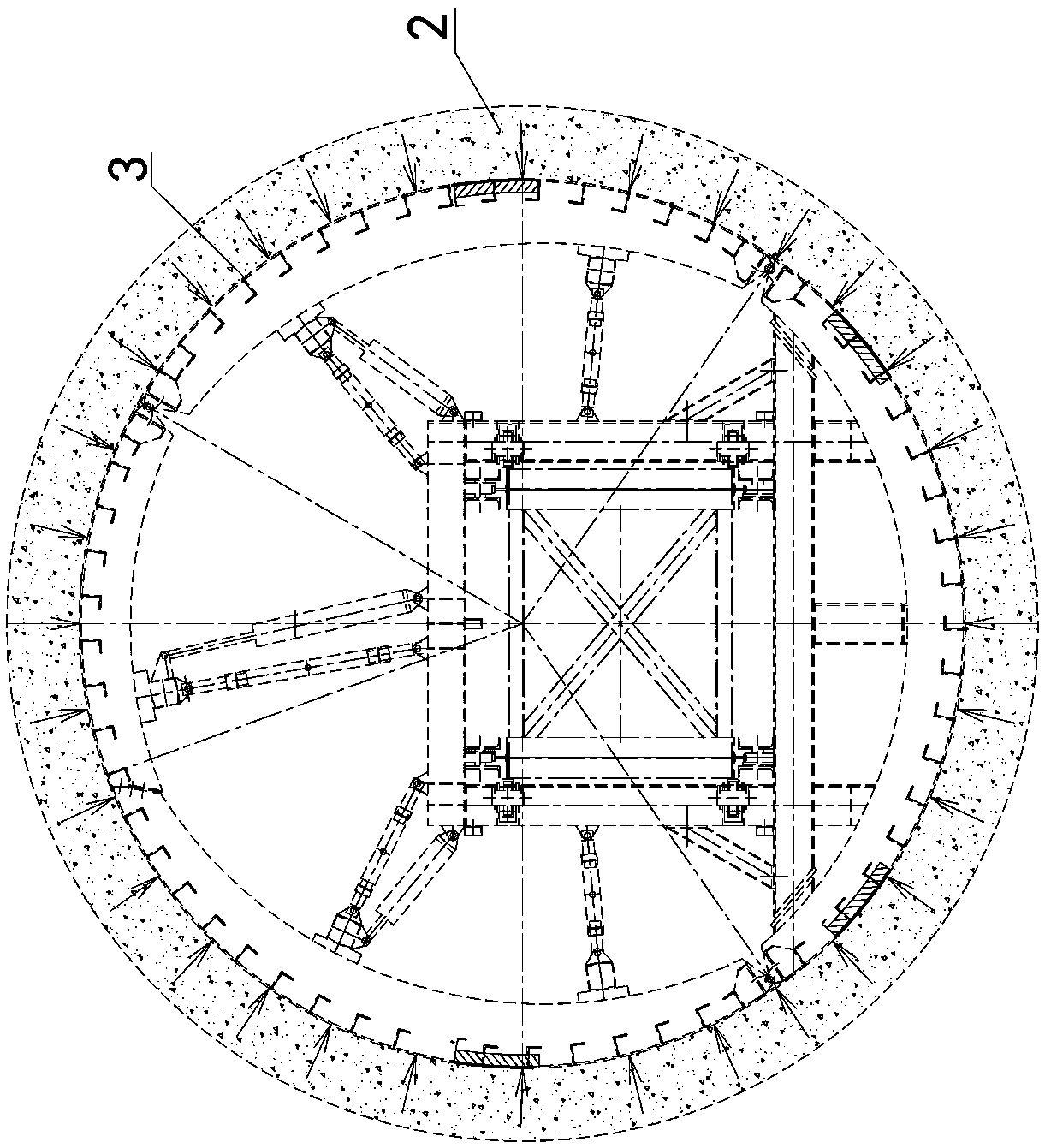

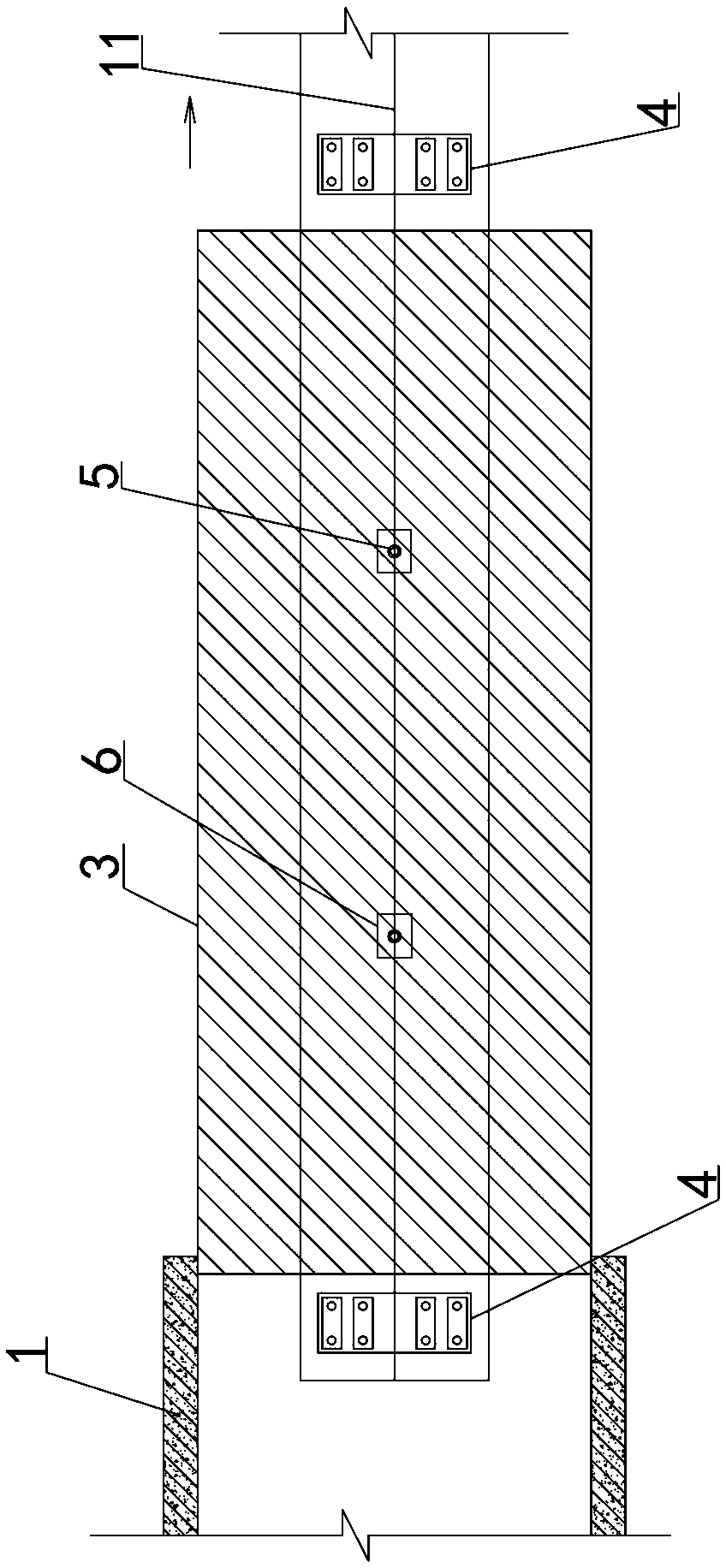

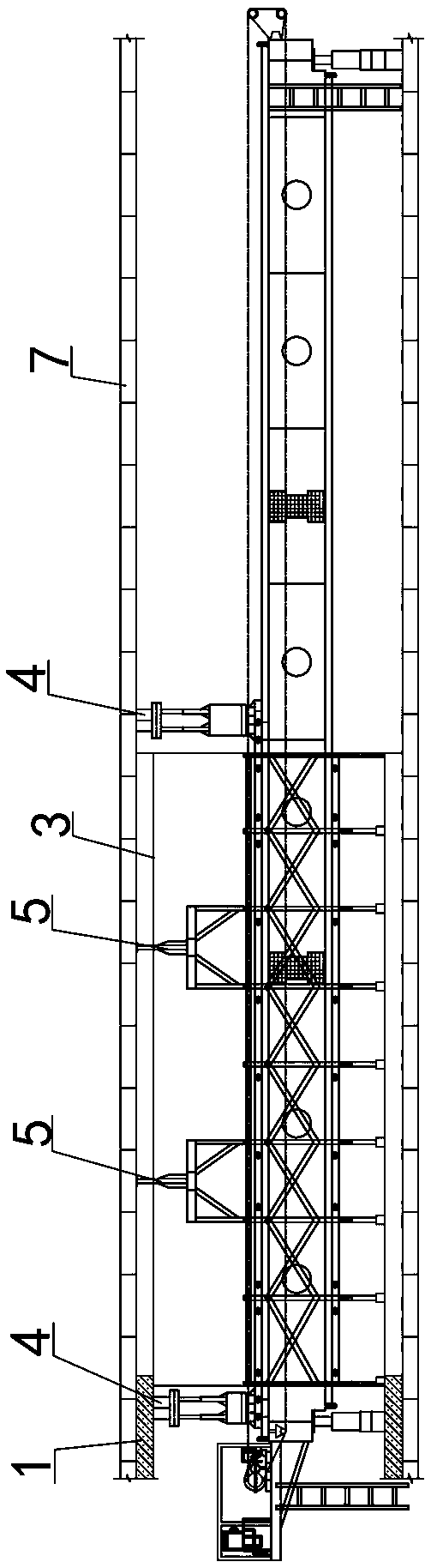

[0049] Examples see Figure 1-9 As shown, taking the construction of the second lining self-compacting concrete of the tunnel poured in the full-circle needle beam formwork trolley as an example, a floating monitoring system and monitoring method for the formwork trolley in the self-compacting concrete are provided. details as follows:

[0050] figure 1 It is a schematic diagram of the floating principle of the trolley. During the pouring process, since the self-compacting concrete 2 is in a fluid state, when the trolley formwork 3 is immersed in the self-compacting concrete 2, the concrete does not initially set, which conforms to Archimedes' principle, so that the trolley formwork 3 is subjected to the buoyancy of the fluid , as the concrete liquid level rises, the buoyancy gradually increases, which will cause the trolley to float up. In actual construction, in order to resist the floating of the trolley, anti-floating devices, namely, the end anti-floating device and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com