A method for evaluating the low temperature cracking resistance of asphalt

A technology of crack resistance and evaluation method, applied in measuring devices, instruments, scientific instruments, etc., can solve the problem that the correlation between creep performance and failure performance is not very good, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

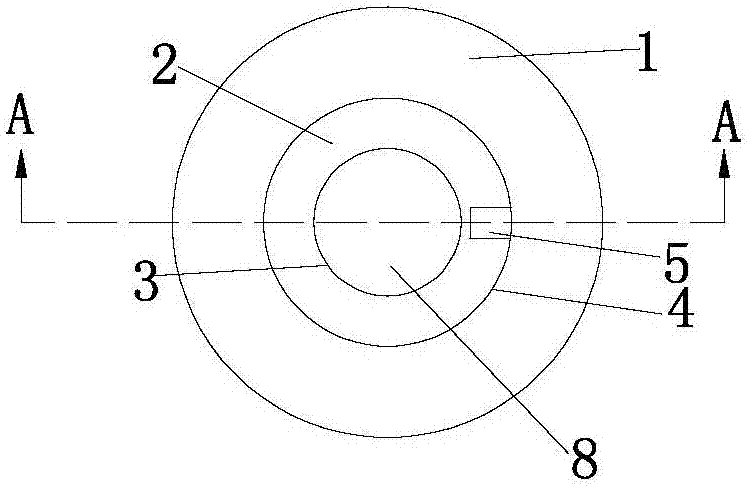

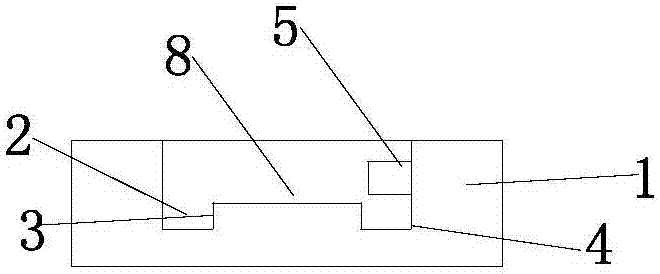

[0048] The invention relates to a ring crack freeze broken disc structure and an asphalt low temperature ring crack tester. An asphalt ring cracked and frozen disc structure includes a base 1 and an inflatable ring 6 . refer to figure 1 , figure 1 It is a top view of the base, the base 1 has an annular groove 2 in the middle, and the base 1 is provided with a synapse 5 on the outer ring wall 4 of the annular groove 2, refer to figure 2 , figure 2 for figure 1 In the cross-sectional view of A-A, the synapse 5 is a cylindrical synapse horizontally arranged on the outer ring wall 4 of the annular groove 2 . The middle of described base 1 is provided with a circular depression 8, and described circular depression 8 is concentric with described annular groove 2, and the radius of described circular depression 8 is equal to the inner ring wall 3 radius of described annular groove 2, and described The depth of the circular depression 8 is smaller than the depth of the annular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com