Temperature field measurement experimenting device and method for break accident of liquid metal reactor heat exchanger

A technology of liquid metal and experimental device, which is used in the monitoring of reactors, nuclear reactors, and greenhouse gas reduction, etc., can solve the problems of endangering the safety of the reactor, blocking the flow of heat transfer tubes, and supercooling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific examples.

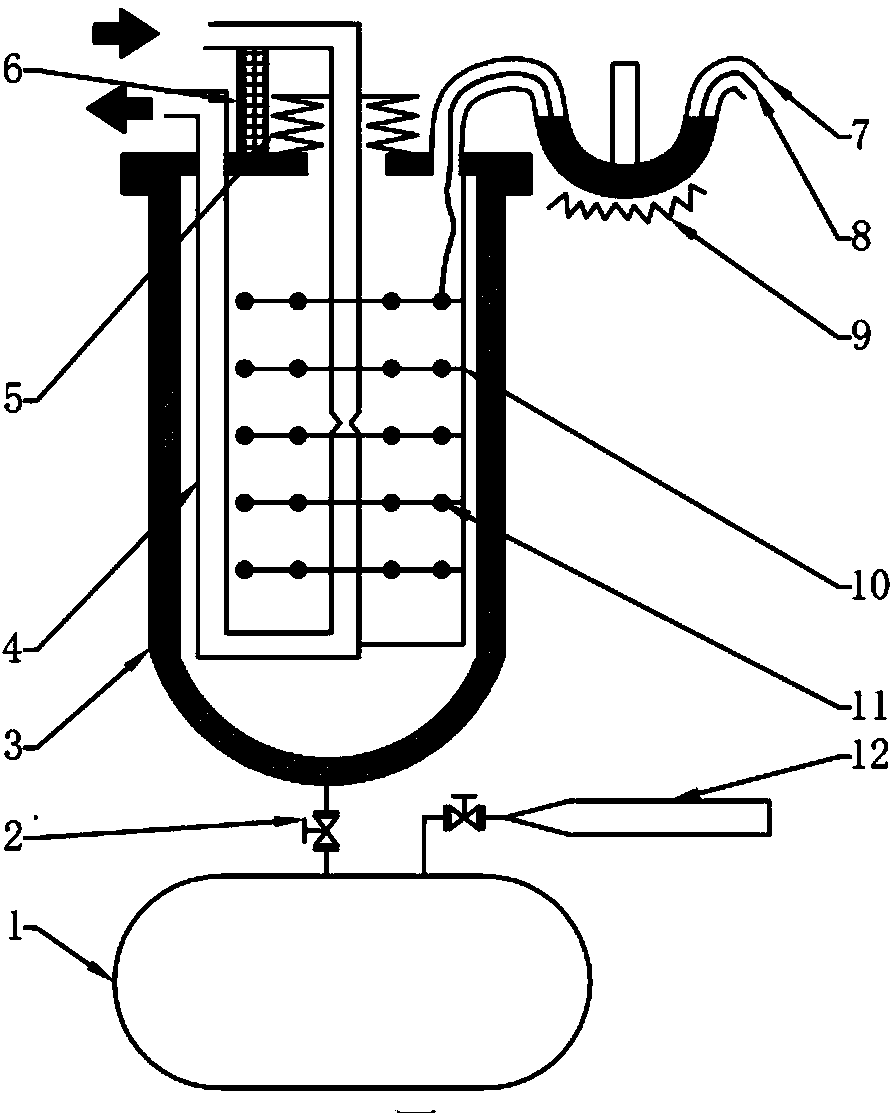

[0019] An experimental device for measuring the temperature field of a liquid metal reactor heat exchanger breach accident, the device consists of a liquid metal storage tank 1, a liquid metal valve 2, a reaction vessel 3, a high-pressure water pipeline 4, a thick-walled bellows 5, a pneumatic hydraulic The pump 6, the thermocouple conduit 7, the thermocouple bundle 8, the heating wire 9, the thermocouple suspension bracket 10, the thermocouple welding point 11 and the protective gas pipeline 12 are composed.

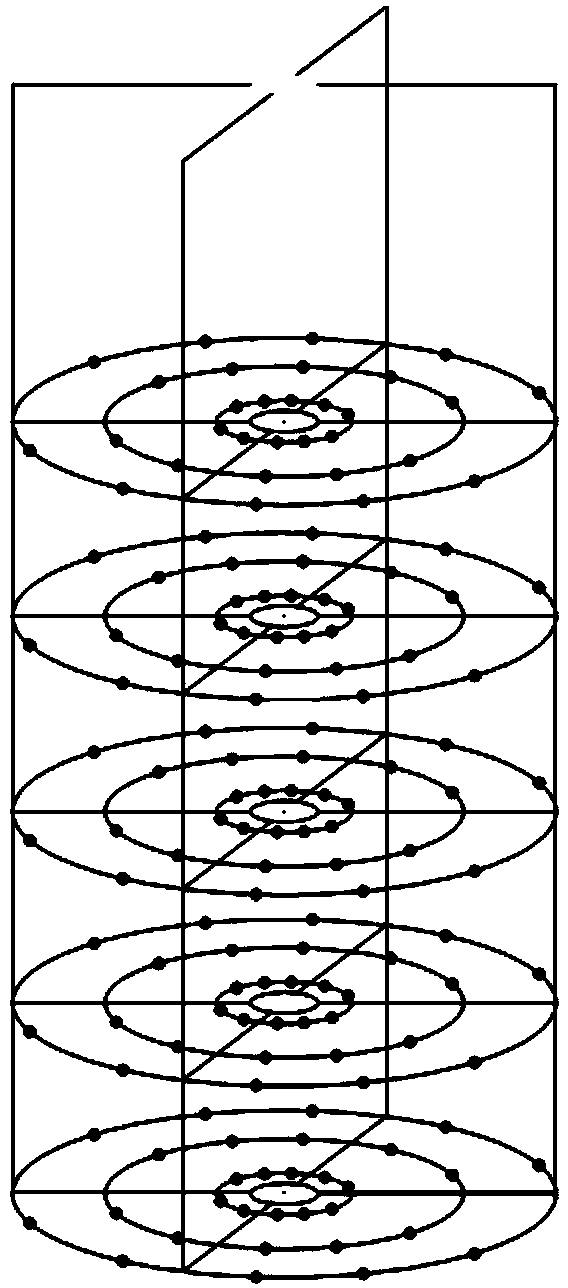

[0020] During the experiment, the thermocouple cluster penetrated into the reaction vessel 3 through the thermocouple conduit 7, and each thermocouple end was fixed on the thermocouple suspension bracket 10 by spot welding, and then the high-temperature lead-bismuth alloy (300° C.) was passed through the thermocouple conduit 7 The vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com